What is slicing in 3d printing – Slicing in 3D printing, a crucial step in the additive manufacturing process, involves converting a 3D model into a series of thin layers, preparing it for printing.

This comprehensive guide delves into the intricacies of slicing, exploring its parameters, software options, material considerations, and advanced techniques, empowering you with the knowledge to optimize your 3D printing outcomes.

Definition of Slicing in 3D Printing

Slicing in 3D printing refers to the process of converting a 3D model into a series of thin, horizontal layers that can be printed sequentially by a 3D printer.

A slicer software is a specialized tool that performs this slicing operation. It takes the 3D model as input and generates a set of instructions called G-code, which contains the precise movements and commands for the 3D printer to follow during the printing process.

Role of Slicer Software

The slicer software plays a crucial role in ensuring the successful and accurate printing of a 3D model. It performs several important functions, including:

- Generating G-code:The slicer software converts the 3D model into a series of G-code instructions that specify the precise movements and commands for the 3D printer.

- Layer height optimization:The slicer software determines the optimal layer height for the print, which affects the resolution and print quality.

- Infill pattern selection:The slicer software allows users to choose the infill pattern for the print, which determines the internal structure of the printed object and affects its strength and weight.

- Support structure generation:The slicer software can automatically generate support structures for overhanging or complex geometries, ensuring that they are printed successfully.

- Print preview:The slicer software provides a preview of the sliced model, allowing users to visualize the print and make adjustments before sending it to the 3D printer.

Slicing Parameters

Slicing parameters play a crucial role in determining the quality of 3D printed parts. These parameters influence various aspects of the printing process, including surface finish, strength, accuracy, and print time. Understanding and optimizing these parameters are essential for achieving high-quality prints.

Key slicing parameters that impact print quality include layer height, infill density, print speed, and extrusion width. Each of these parameters has specific effects on the printed part, as summarized in the table below:

| Parameter | Effect on Print Quality |

|---|---|

| Layer Height | Lower layer heights result in smoother surfaces and finer details, but increase print time. |

| Infill Density | Higher infill densities increase part strength and reduce warping, but also increase print time and material usage. |

| Print Speed | Slower print speeds produce higher quality prints with reduced layer lines, but increase print time. |

| Extrusion Width | Wider extrusion widths increase material flow rate, which can improve print speed and reduce print time, but can also lead to overextrusion and reduced print quality. |

The optimal slicing parameters for a given print depend on the specific material, printer, and desired print quality. Experimenting with different slicing parameters is a good way to find the best settings for your particular application.

Different Slicing Software

Slicing software is a crucial component of 3D printing, as it translates 3D models into instructions that the printer can understand. There are several popular slicing software options available, each with its own advantages and disadvantages.

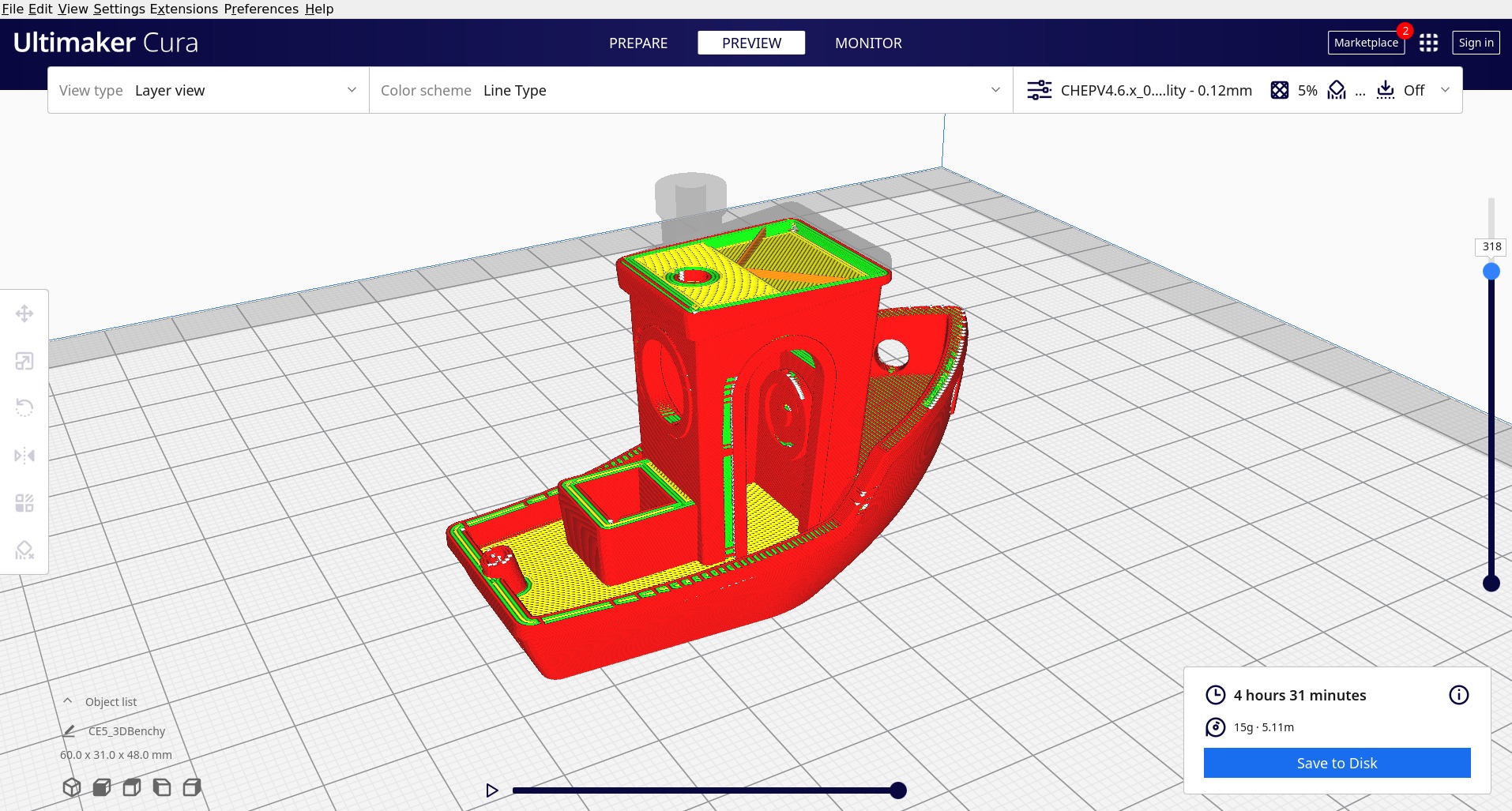

Cura

Cura is a free and open-source slicing software developed by Ultimaker. It is widely used due to its user-friendly interface, extensive features, and active community support. Cura offers a wide range of settings, allowing users to fine-tune their prints for optimal quality.

Simplify3D

Simplify3D is a commercial slicing software known for its advanced features and reliability. It offers a wide range of customization options, including the ability to create custom support structures and fine-tune printing parameters. Simplify3D is particularly popular among experienced users who demand the highest quality prints.

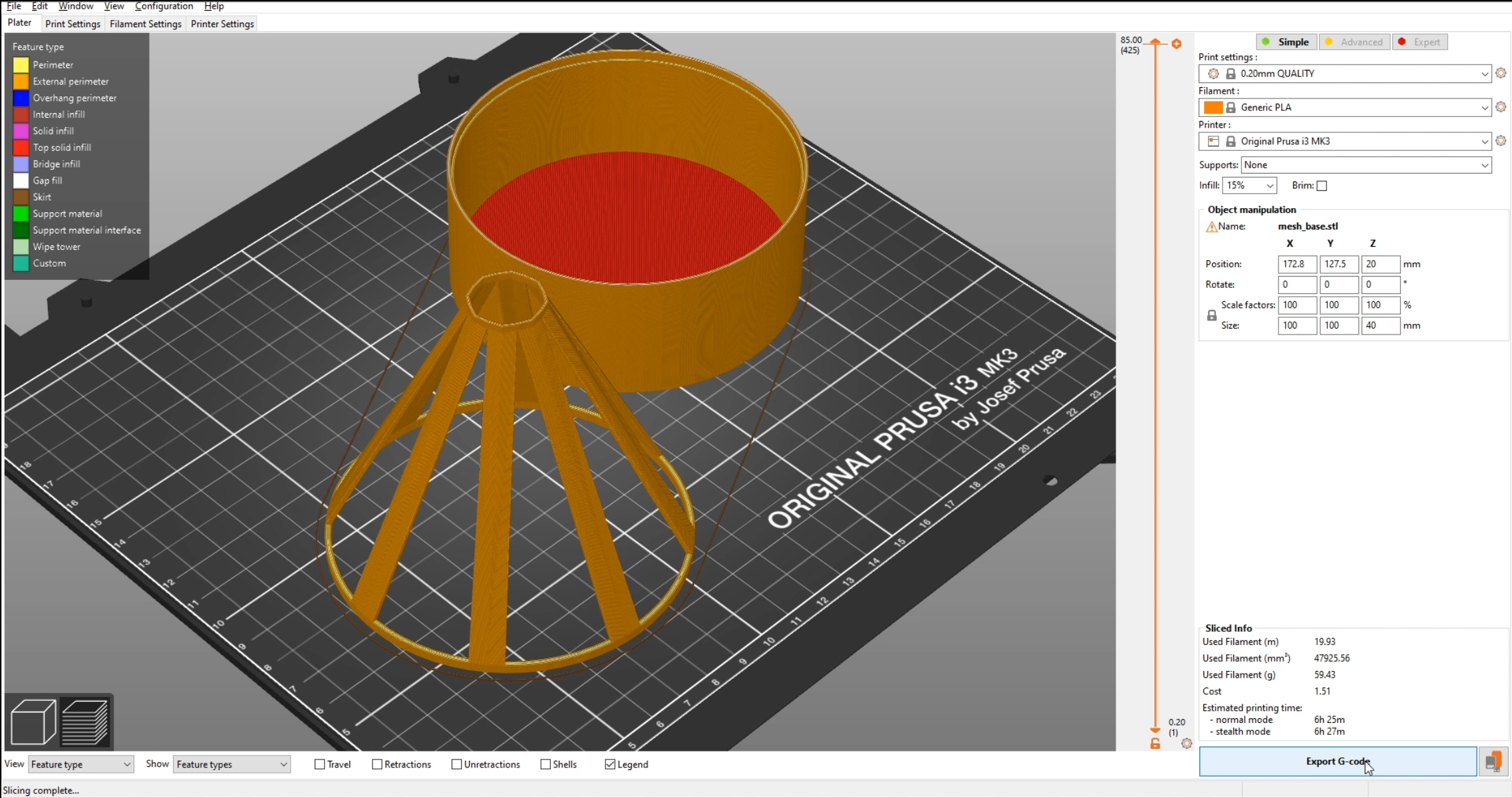

PrusaSlicer

PrusaSlicer is a free and open-source slicing software developed by Prusa Research. It is designed specifically for Prusa printers but can be used with other printers as well. PrusaSlicer offers a user-friendly interface and a range of features tailored to Prusa printers, such as automatic bed leveling and filament profiles.

Comparison of Features

| Feature | Cura | Simplify3D | PrusaSlicer |

|---|---|---|---|

| Price | Free | Commercial | Free |

| Interface | User-friendly | Advanced | User-friendly |

| Customization options | Extensive | Very extensive | Tailored to Prusa printers |

| Community support | Active | Good | Excellent |

| Target audience | Beginners to experienced users | Experienced users | Prusa printer users |

Unique Features and Target Audience

Cura is suitable for both beginners and experienced users due to its user-friendly interface and extensive features. Simplify3D is best suited for experienced users who demand the highest quality prints and are willing to pay for advanced features. PrusaSlicer is ideal for Prusa printer users as it offers tailored features and excellent community support.

Recommendations

For beginners or those looking for a free and user-friendly option, Cura is a great choice. For experienced users who prioritize advanced features and reliability, Simplify3D is recommended. PrusaSlicer is the best choice for Prusa printer users who want tailored features and excellent community support.

Slicing for Different Materials

Slicing parameters play a crucial role in determining the quality and success of 3D prints. Different 3D printing materials possess unique properties that necessitate tailored slicing settings to optimize print outcomes. Understanding the material properties and their impact on slicing parameters is essential for achieving optimal results.

PLA (Polylactic Acid)

PLA is a widely used material known for its ease of printing and low warping tendency. Its low melting temperature (180-210°C) and glass transition temperature (60-65°C) allow for faster printing speeds and reduced layer heights. Recommended slicing settings for PLA include a layer height of 0.1-0.2mm, infill density of 15-25%, and print speed of 50-70mm/s.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable material with a higher melting temperature (230-250°C) and glass transition temperature (105°C) compared to PLA. These properties necessitate slower printing speeds and higher layer heights to prevent warping and ensure proper layer adhesion. Recommended slicing settings for ABS include a layer height of 0.2-0.3mm, infill density of 25-35%, and print speed of 40-60mm/s.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the strength of ABS with the ease of printing of PLA. It has a slightly higher melting temperature (240-260°C) and glass transition temperature (75-85°C) than ABS. Slicing settings for PETG should consider its tendency to string, requiring slightly higher retraction settings.

Recommended settings include a layer height of 0.2-0.3mm, infill density of 20-30%, and print speed of 50-70mm/s.

TPU (Thermoplastic Polyurethane)

TPU is a flexible material with a low tensile strength and high elongation at break. Its unique properties require specialized slicing settings to prevent excessive deformation and ensure proper adhesion between layers. Recommended settings for TPU include a layer height of 0.1-0.2mm, infill density of 10-20%, and print speed of 20-40mm/s.

Nylon

Nylon is a strong and durable material with a high melting temperature (240-260°C) and glass transition temperature (145°C). Its high tensile strength and low friction coefficient make it suitable for functional parts and engineering applications. Slicing settings for nylon should consider its tendency to absorb moisture, requiring dry storage conditions.

Recommended settings include a layer height of 0.1-0.2mm, infill density of 30-40%, and print speed of 40-60mm/s.

| Material | Layer Height (mm) | Infill Density (%) | Print Speed (mm/s) |

|---|---|---|---|

| PLA | 0.1-0.2 | 15-25 | 50-70 |

| ABS | 0.2-0.3 | 25-35 | 40-60 |

| PETG | 0.2-0.3 | 20-30 | 50-70 |

| TPU | 0.1-0.2 | 10-20 | 20-40 |

| Nylon | 0.1-0.2 | 30-40 | 40-60 |

Slicing for Complex Geometries

Slicing complex 3D models presents unique challenges due to intricate geometries, overhangs, bridges, and small features. Optimizing slicing settings for these geometries is crucial to ensure successful printing and high-quality results.

To address overhangs, supports can be added to prevent drooping or collapse during printing. Bridges require careful adjustment of parameters like bridging speed and fan speed to maintain structural integrity. Small features benefit from higher layer heights and slower printing speeds to preserve detail.

Recommended Slicing Settings for Complex Geometries

The following table summarizes recommended slicing settings for different types of complex geometries:

| Geometry | Layer Height | Printing Speed | Bridging Speed | Fan Speed | Supports |

|---|---|---|---|---|---|

| Overhangs | Small | Slow | N/A | High | Yes |

| Bridges | Small | Slow | Slow | High | No |

| Small Features | Small | Slow | N/A | Low | No |

Code Snippet

The following code snippet demonstrates how to apply these settings in a slicing software:

“`layer_height = 0.1mmprinting_speed = 20mm/sbridging_speed = 10mm/sfan_speed = 100%supports = True“`

Importance of Slicing Optimization for Complex Geometries

Slicing optimization for complex geometries is essential for successful printing and high-quality results. By optimizing slicing settings, it is possible to:

- Prevent overhangs from drooping or collapsing

- Maintain structural integrity of bridges

- Preserve fine details in small features

Proper slicing optimization ensures that the final print accurately reflects the intended design, with minimal defects or imperfections.

Advanced Slicing Features

Slicing software offers advanced features that enhance print quality and efficiency, including variable layer height and adaptive slicing.

Variable Layer Height

Variable layer height adjusts the layer height throughout the print, creating a smoother surface finish and reducing print time. Thicker layers are used in less detailed areas, while thinner layers are employed in areas requiring higher precision.

Adaptive Slicing

Adaptive slicing optimizes the layer height and printing parameters based on the model’s geometry. It automatically adjusts the layer height, infill density, and other settings to ensure optimal print quality and efficiency.

Comparison of Variable Layer Height and Adaptive Slicing

| Feature | Variable Layer Height | Adaptive Slicing |

|---|---|---|

| Layer Height Adjustment | Manual adjustment | Automatic adjustment based on model geometry |

| Print Quality | Improved surface finish | Optimized print quality throughout the model |

| Print Time | Reduced print time | Optimized print time based on model geometry |

| Complexity | Less complex to implement | More complex to implement, requires advanced algorithms |

Code Block: Implementing Advanced Slicing Features

“`// Example code to implement variable layer height in a slicing softwaredef set_layer_height(layer_height): # Set the layer height for the entire modeldef set_variable_layer_height(layer_heights): # Set different layer heights for different regions of the model// Example code to implement adaptive slicing in a slicing softwaredef set_adaptive_slicing(enabled): # Enable or disable adaptive slicingdef set_adaptive_parameters(parameters): # Set the parameters for adaptive slicing, such as the minimum and maximum layer height“`

Example of a Print Benefitting from Advanced Slicing Features, What is slicing in 3d printing

A complex model with both large, flat surfaces and intricate details can benefit from variable layer height and adaptive slicing. The large surfaces can be printed with thicker layers for speed, while the intricate details can be printed with thinner layers for precision.

Tips for Optimal Slicing

Optimizing slicing settings can significantly enhance the quality and efficiency of 3D prints. Here are some practical tips for achieving optimal results:

Consider the material properties and printer capabilities. Different materials have specific slicing requirements, such as layer height, infill density, and printing temperature. It’s crucial to consult the material’s datasheet and printer specifications to determine the optimal settings.

Troubleshooting Common Slicing Issues

Common slicing issues include over-extrusion, under-extrusion, warping, and stringing. Over-extrusion occurs when too much material is deposited, leading to bulging and rough surfaces. Under-extrusion results in gaps and missing layers. Warping is caused by uneven cooling, leading to distortion of the print.

Stringing occurs when molten material forms thin threads between parts of the print.

To troubleshoot these issues, check the following:

- Ensure the nozzle temperature and bed temperature are within the recommended range for the material.

- Adjust the flow rate or extrusion multiplier to control the amount of material deposited.

- Enable cooling features, such as a cooling fan or draft shield, to prevent warping.

- Reduce retraction distance and speed to minimize stringing.

Optimal Slicing Settings for Different Materials

The following table provides a summary of optimal slicing settings for common 3D printing materials:

| Material | Layer Height (mm) | Infill Density (%) | Printing Temperature (°C) |

|---|---|---|---|

| PLA | 0.15-0.25 | 20-50 | 200-220 |

| ABS | 0.15-0.3 | 30-60 | 230-250 |

| PETG | 0.15-0.25 | 20-50 | 230-250 |

| TPU | 0.15-0.3 | 10-30 | 200-230 |

Troubleshooting Guide

Here’s a troubleshooting guide for common slicing problems:

- Problem:Over-extrusion Solution:Reduce flow rate or extrusion multiplier.

- Problem:Under-extrusion Solution:Increase flow rate or extrusion multiplier, check for nozzle clogs.

- Problem:Warping Solution:Enable cooling fan or draft shield, adjust bed temperature.

- Problem:Stringing Solution:Reduce retraction distance and speed, enable retraction settings.

Code Snippet: Adjusting Slicing Settings

Here’s a code snippet demonstrating how to adjust slicing settings in Cura, a popular slicing software:

; Set layer height layer_height = 0.2 ; Set infill density infill_density = 50 ; Set printing temperature initial_printing_temperature = 200

Advanced Slicing Techniques

Advanced slicing techniques can be employed to achieve specific effects, such as:

- Vase Mode:Prints a single-wall object without infill, resulting in a lightweight and hollow print.

- Adaptive Layers:Adjusts layer height based on the geometry of the model, resulting in finer details in critical areas and faster printing in less detailed areas.

- Supports:Generates temporary structures that support overhanging or complex geometries during printing, preventing collapse.

– Case Studies

Slicing plays a crucial role in various applications of 3D printing, including prototyping, manufacturing, and art. Each application presents unique challenges that require tailored slicing solutions.

In prototyping, slicing techniques can optimize print speed and accuracy, enabling rapid iteration and design validation. For manufacturing applications, slicing can maximize material efficiency, reduce production costs, and ensure the structural integrity of printed parts.

– Prototyping

- Slicing for rapid prototyping prioritizes print speed and dimensional accuracy.

- Adaptive slicing algorithms can adjust layer heights and infill densities based on part geometry, reducing print time without compromising detail.

- Multi-material slicing allows for the printing of complex prototypes with different material properties in a single build.

– Manufacturing

- Slicing for manufacturing focuses on material efficiency and structural integrity.

- Topology optimization techniques can generate lightweight and robust part designs that minimize material usage.

- Specialized slicing software for manufacturing applications offers features such as support generation for large and complex parts.

– Art

- Slicing for art applications emphasizes surface quality and aesthetics.

- Advanced slicing techniques, such as multi-material slicing and adaptive layer heights, enable the creation of intricate and visually appealing prints.

- Slicing software specifically designed for art applications provides tools for manipulating and enhancing the appearance of 3D models.

By understanding the unique requirements of each application, slicing techniques can be tailored to achieve optimal results in terms of print quality, efficiency, and cost-effectiveness.

Emerging Trends in Slicing

Slicing technology is continuously evolving, with new trends emerging to enhance the efficiency, accuracy, and capabilities of 3D printing. These trends include:

AI and Machine Learning in Slicing

Artificial intelligence (AI) and machine learning (ML) are transforming the slicing process. AI algorithms can analyze large datasets of 3D models and printing parameters to identify patterns and optimize slicing settings for specific materials and printers. ML models can also be trained to predict the optimal slicing parameters for complex geometries, reducing the need for manual trial and error.

The integration of AI and ML in slicing software has the potential to significantly improve the quality and efficiency of 3D printing. It can automate the optimization process, reduce the time required to generate slices, and enhance the overall user experience.

Comparison of Slicing Techniques

Slicing techniques are crucial in 3D printing, influencing the quality, efficiency, and cost of the final product. Here, we compare three common slicing techniques: adaptive slicing, volumetric slicing, and topology optimization, highlighting their advantages and limitations.

Adaptive Slicing

- Adjusts slice thickness based on model geometry, resulting in finer slices in detailed areas and thicker slices in less complex regions.

- Advantages:

- Improved surface quality in intricate areas.

- Reduced printing time and material consumption.

- Limitations:

- May require longer slicing times.

- Not suitable for all model geometries.

Volumetric Slicing

- Divides the model into voxels (3D pixels) and generates slices based on voxel data.

- Advantages:

- Supports complex geometries with internal cavities and overhangs.

- Enables precise control over material distribution.

- Limitations:

- Computationally intensive, leading to longer slicing times.

- May result in larger file sizes.

Topology Optimization

- Uses mathematical algorithms to optimize the internal structure of the model, removing unnecessary material while maintaining structural integrity.

- Advantages:

- Significant material savings.

- Improved mechanical properties.

- Limitations:

- Requires specialized software and expertise.

- Can compromise surface finish.

The choice of slicing technique depends on the specific model geometry, material properties, and desired outcomes. Adaptive slicing is suitable for models with varying complexity, while volumetric slicing excels in handling intricate geometries. Topology optimization is ideal for optimizing material usage and improving mechanical performance.

Optimizing Slicing for Speed and Efficiency

Optimizing slicing settings can significantly reduce printing time and improve efficiency in 3D printing. This involves finding the right balance between speed, quality, and material usage. By understanding the impact of different slicing parameters, users can tailor their settings to achieve the desired results for their specific projects.

Slicing Parameters

- Layer height:Thinner layers produce higher quality prints but increase printing time.

- Infill density:Higher infill densities increase strength but use more material and increase printing time.

- Print speed:Faster print speeds reduce printing time but can compromise quality.

- Travel speed:Optimizing travel speed can minimize non-printing time and improve efficiency.

- Retraction settings:Proper retraction settings reduce stringing and improve print quality, but can impact printing speed.

Trade-offs

The key to optimizing slicing for speed and efficiency is to understand the trade-offs involved. For example, reducing layer height will improve quality but increase printing time. Similarly, increasing infill density will enhance strength but use more material and extend printing time.

It’s essential to prioritize the desired outcomes and adjust slicing parameters accordingly.

Strategies

- Use larger layer heights:For less detailed prints, using larger layer heights can significantly reduce printing time without compromising overall quality.

- Reduce infill density:For non-load-bearing parts, reducing infill density can save material and printing time while maintaining adequate strength.

- Optimize print speed:Determine the optimal print speed that balances quality and efficiency.

Avoid excessively high speeds that can lead to poor print quality.

- Minimize travel time:Adjust travel speed and retraction settings to reduce non-printing time. This can be achieved by enabling features like “combing” or “avoid crossing perimeters.”

- Use fast slicing algorithms:Certain slicing software offers fast slicing algorithms that can significantly reduce slicing time, especially for complex models.

– Slicing for Multi-Material Printing

Slicing for multi-material 3D printing poses unique challenges due to the need to coordinate multiple materials with different properties. Optimizing slicing settings is crucial for achieving high-quality multi-material prints.

When slicing for multi-material printing, several factors must be considered, including the compatibility of materials, the desired print quality, and the printer’s capabilities.

Material Compatibility

The first step is to ensure that the selected materials are compatible for multi-material printing. Different materials have different melting temperatures, flow rates, and shrinkage rates, which can affect the print quality if not properly accounted for.

Print Quality

The desired print quality also influences the slicing settings. Higher print quality requires finer layer heights and slower print speeds, while lower print quality allows for faster printing and coarser layer heights.

Printer Capabilities

The printer’s capabilities also limit the slicing settings that can be used. Some printers may not be able to handle certain materials or print at certain speeds or resolutions.

Optimizing Slicing Settings

To optimize slicing settings for multi-material printing, it is important to experiment with different combinations of settings and observe the results. Some general guidelines include:

- Use a compatible slicer that supports multi-material printing.

- Select materials that are compatible with each other.

- Use a fine layer height for higher print quality.

- Print at a slow speed to allow for proper material flow.

- Adjust the temperature and flow rate settings for each material as needed.

By following these guidelines and experimenting with different slicing settings, it is possible to achieve high-quality multi-material prints.

Creating Custom Slicing Profiles

Creating custom slicing profiles allows for tailored settings to specific materials, printers, and applications. This enables optimal results by fine-tuning parameters like layer height, infill density, and print speed.

Parameters to Consider

* Layer Height:Affects print quality and build time. Lower layers produce smoother surfaces but take longer to print.

Infill Density

In 3D printing, slicing is a crucial step that involves converting a 3D model into a series of 2D layers that the printer can build up layer by layer. Similarly, when printing a Frontier boarding pass, the printer must translate the digital information into a physical document.

Just as slicing optimizes 3D printing, understanding the specific requirements for printing Frontier boarding passes, such as the correct settings and paper type , ensures a successful print. By understanding both slicing in 3D printing and the nuances of printing Frontier boarding passes, users can achieve optimal results in their respective domains.

Determines the internal structure of the print. Higher densities provide greater strength but increase material usage and print time.

Print Speed

Balances print quality and time. Slower speeds produce higher-quality prints but take longer.

Material

Different materials have unique properties that require specific slicing settings. For example, flexible materials may require lower print speeds and higher layer heights.

Fine-Tuning Settings

Fine-tuning slicing settings involves experimenting with different values and observing the results. Start with recommended settings and gradually adjust them until the desired outcome is achieved. Consider factors such as:* Printer Capabilities:The printer’s capabilities limit the range of slicing parameters that can be used.

Application Requirements

The intended use of the print may dictate specific slicing settings. For example, functional parts may require higher infill densities.

Material Properties

The material’s properties influence the optimal slicing settings. For instance, materials with high thermal conductivity may require lower print speeds to prevent warping.By understanding these parameters and fine-tuning settings, custom slicing profiles can be created to optimize print quality, reduce print time, and achieve desired results for specific materials, printers, and applications.

Using Slicing Software to Repair and Prepare Models

Slicing software not only slices models into layers for printing but also provides tools for repairing and preparing models for printing. These tools can help fix errors in the model, optimize the geometry for better printing, and add supports to ensure the model prints successfully.

Fixing Errors

Slicing software can identify and fix various errors in the model, such as holes, non-manifold edges, and self-intersections. These errors can cause problems during printing, such as gaps in the printed model or the model detaching from the build plate.

The software can automatically repair these errors or provide tools for manual repair.

In 3D printing, slicing refers to the process of converting a 3D model into a series of thin layers, which are then printed one by one to create the final object. Similar to the concept of collating in printing, where multiple pages are gathered and arranged in the correct order, slicing in 3D printing ensures that each layer is printed in the proper sequence to form the desired shape.

This process involves generating a G-code file that contains instructions for the printer to follow, guiding the precise movement of the print head and deposition of material.

Optimizing Geometry

Slicing software can also be used to optimize the geometry of the model for better printing. This can involve simplifying the geometry to reduce the number of polygons, which can improve printing speed and reduce file size. The software can also optimize the orientation of the model on the build plate to minimize overhangs and support material usage.

Adding Supports

Supports are structures that are printed along with the model to provide additional support during printing. Supports are necessary for models with overhangs or complex geometries that would otherwise collapse during printing. Slicing software can automatically generate supports or provide tools for manually adding supports.

Slicing for Large-Scale 3D Printing: What Is Slicing In 3d Printing

Slicing for large-scale 3D printing poses unique challenges and requires careful consideration to ensure successful printing. Unlike smaller models, large-scale prints demand specific adjustments in slicing settings to accommodate their size, weight, and potential structural weaknesses.

Optimizing Slicing Settings for Large Models

Optimizing slicing settings for large models involves several key considerations:

- Layer Height:Thicker layer heights can significantly reduce printing time for large models, but they may compromise surface quality. Finding a balance between speed and quality is crucial.

- Infill Density:Large models require sufficient infill density to provide structural support and prevent warping. However, excessive infill can increase print time and material usage.

- Print Speed:Printing large models at high speeds can lead to layer shifts and other print defects. It is recommended to reduce print speed to ensure stability and print quality.

- Cooling:Large models generate more heat during printing, which can cause warping and layer delamination. Increasing cooling fan speed and using a cooling enclosure can help mitigate these issues.

Commonly Asked Questions

What is the role of a slicer in 3D printing?

A slicer software translates a 3D model into a series of thin layers, providing instructions to the 3D printer on how to build the object one layer at a time.

How do slicing parameters influence print quality?

Slicing parameters such as layer height, infill density, print speed, and extrusion width significantly impact print quality, affecting factors like surface smoothness, strength, and printing time.

What are the advantages of using different slicing software options?

Various slicing software options offer unique features and capabilities, allowing users to customize slicing settings, optimize print quality, and cater to specific printing needs.

How does slicing affect the printing of different materials?

Slicing parameters must be tailored to the specific material being printed, as material properties like melting temperature and tensile strength influence optimal layer height, infill density, and print speed.

What are some advanced slicing techniques for complex geometries?

Advanced slicing techniques like adaptive slicing and variable layer height can optimize slicing for complex geometries, ensuring successful printing of overhangs, bridges, and intricate details.