What is printer ink made of? This question delves into the composition of printer ink, exploring its primary components, their roles, and the manufacturing process. Understanding the chemistry behind printer ink is essential for optimizing print quality, maintaining printers, and reducing environmental impact.

The composition of printer ink involves a blend of pigments, dyes, solvents, and resins. Pigments are insoluble particles that provide color and opacity, while dyes are soluble and offer a wider color gamut. Solvents dissolve and disperse the other components, ensuring smooth ink flow.

Resins bind the ink components together, affecting its durability and printability.

Composition of Printer Ink: What Is Printer Ink Made Of

Printer ink is a complex mixture of pigments, dyes, solvents, and resins. These components work together to create the desired color, opacity, and durability of the printed image.

Pigments and Dyes

Pigments are insoluble particles that give ink its color. They are typically made of inorganic materials, such as carbon black or titanium dioxide. Dyes, on the other hand, are soluble in the ink solvent and are typically made of organic materials.

Both pigments and dyes can be used to create a wide range of colors, but pigments are generally more lightfast and durable than dyes.

Solvents

Solvents are used to dissolve the pigments and dyes in ink. They also help to control the ink’s viscosity and surface tension. Common solvents used in printer ink include water, alcohol, and glycol ethers.

Resins

Resins are used to bind the pigments and dyes together and to create a durable film on the printed surface. They can also be used to control the ink’s gloss and flexibility.

Types of Printer Ink

Printer inks come in various types, each with its unique characteristics and applications. Understanding the different types of printer ink helps users make informed choices based on their printing needs and preferences.

Dye-Based Ink

Dye-based inks are commonly used in inkjet printers. They contain water-soluble dyes that produce vibrant colors and smooth transitions. Dye-based inks are relatively inexpensive and offer high-quality prints for everyday use, such as documents, photos, and marketing materials.

Advantages:

- Vibrant colors and smooth transitions

- Cost-effective

- Widely available

Disadvantages:

- Lower durability compared to pigment-based inks

- Susceptible to fading and water damage

- May not be suitable for professional or archival applications

Pigment-Based Ink

Pigment-based inks utilize insoluble pigments suspended in a carrier fluid. These inks offer superior durability and resistance to fading and water damage, making them ideal for professional printing, archival documents, and outdoor applications.

Advantages:

- Excellent durability and resistance to fading

- Suitable for professional and archival applications

- Produces sharp and detailed prints

Disadvantages:

- Less vibrant colors compared to dye-based inks

- Higher cost than dye-based inks

- May require specialized printers

Solid Ink

Solid ink, also known as phase-change ink, is a unique type of ink used in solid ink printers. It consists of solid wax-like sticks that melt and solidify on the paper during the printing process. Solid ink produces high-quality prints with excellent durability and resistance to fading.

Advantages:

- Exceptional durability and fade resistance

- Produces sharp and vibrant prints

- Compact and portable printers

Disadvantages:

- Higher cost compared to other ink types

- Limited availability of printers and inks

- May not be suitable for high-volume printing

Manufacturing Process of Printer Ink

The manufacturing process of printer ink involves several key steps to ensure consistent performance and reliability. These steps include raw material preparation, mixing, filtration, and packaging.

Raw Material Preparation

The first step in the manufacturing process is the preparation of raw materials. These materials include pigments, resins, solvents, and additives. Pigments provide the color to the ink, while resins bind the pigments together and give the ink its viscosity.

Solvents dissolve the pigments and resins, and additives improve the ink’s performance and stability.

Mixing

Once the raw materials are prepared, they are mixed together in a controlled environment. The mixing process is critical to ensure that the ink has the desired properties, such as color, viscosity, and surface tension. The mixing process can be done in a variety of ways, depending on the type of ink being manufactured.

Filtration

After mixing, the ink is filtered to remove any impurities or undissolved particles. Filtration is important to ensure that the ink is free of contaminants that could clog the printer nozzles or affect the print quality.

Packaging

The final step in the manufacturing process is packaging. The ink is packaged in cartridges or bottles that are designed to protect the ink from air and light. The packaging also includes information about the ink, such as the color, type, and shelf life.

Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the consistent performance and reliability of the ink. These measures include:

- Raw material testing: The raw materials are tested to ensure that they meet the required specifications.

- Process monitoring: The manufacturing process is monitored to ensure that it is operating within the specified parameters.

- Finished product testing: The finished ink is tested to ensure that it meets the desired performance and quality standards.

Environmental Impact of Printer Ink

Printer ink production and disposal raise environmental concerns due to the emission of volatile organic compounds (VOCs), wastewater generation, and improper cartridge disposal leading to soil contamination.

Sustainable practices like refillable ink cartridges, cartridge recycling, and printers with built-in ink tanks reduce the environmental footprint. Opting for low-VOC inks and proper waste management practices further minimize the impact.

Air Pollution from VOCs

VOCs released during ink production and cartridge disposal contribute to air pollution. These compounds react with sunlight to form ground-level ozone, a harmful pollutant that can cause respiratory issues and damage vegetation.

Water Pollution from Wastewater, What is printer ink made of

Wastewater generated during ink production and disposal contains pollutants that can contaminate water bodies. These pollutants include heavy metals, solvents, and other chemicals that can harm aquatic life and disrupt ecosystems.

Soil Contamination from Improper Disposal

Improper disposal of ink cartridges in landfills can lead to soil contamination. The cartridges contain toxic substances that can leach into the soil and groundwater, posing risks to human health and the environment.

Sustainable Practices for Reducing Environmental Impact

- Refillable Ink Cartridges:Reusing cartridges reduces waste and the production of new cartridges, conserving resources and minimizing landfill waste.

- Recycling Used Ink Cartridges:Recycling programs collect and process used cartridges, recovering materials for reuse and reducing the need for raw material extraction.

- Printers with Built-in Ink Tanks:These printers eliminate the need for disposable cartridges, significantly reducing waste and the environmental impact of cartridge production and disposal.

- Low-VOC Inks:Choosing inks with low VOC emissions minimizes air pollution during production and disposal, improving air quality.

- Proper Waste Management Practices:Implementing proper waste management practices, such as designated recycling bins for ink cartridges, ensures proper disposal and reduces the risk of soil contamination.

Specific Examples of Sustainable Practices

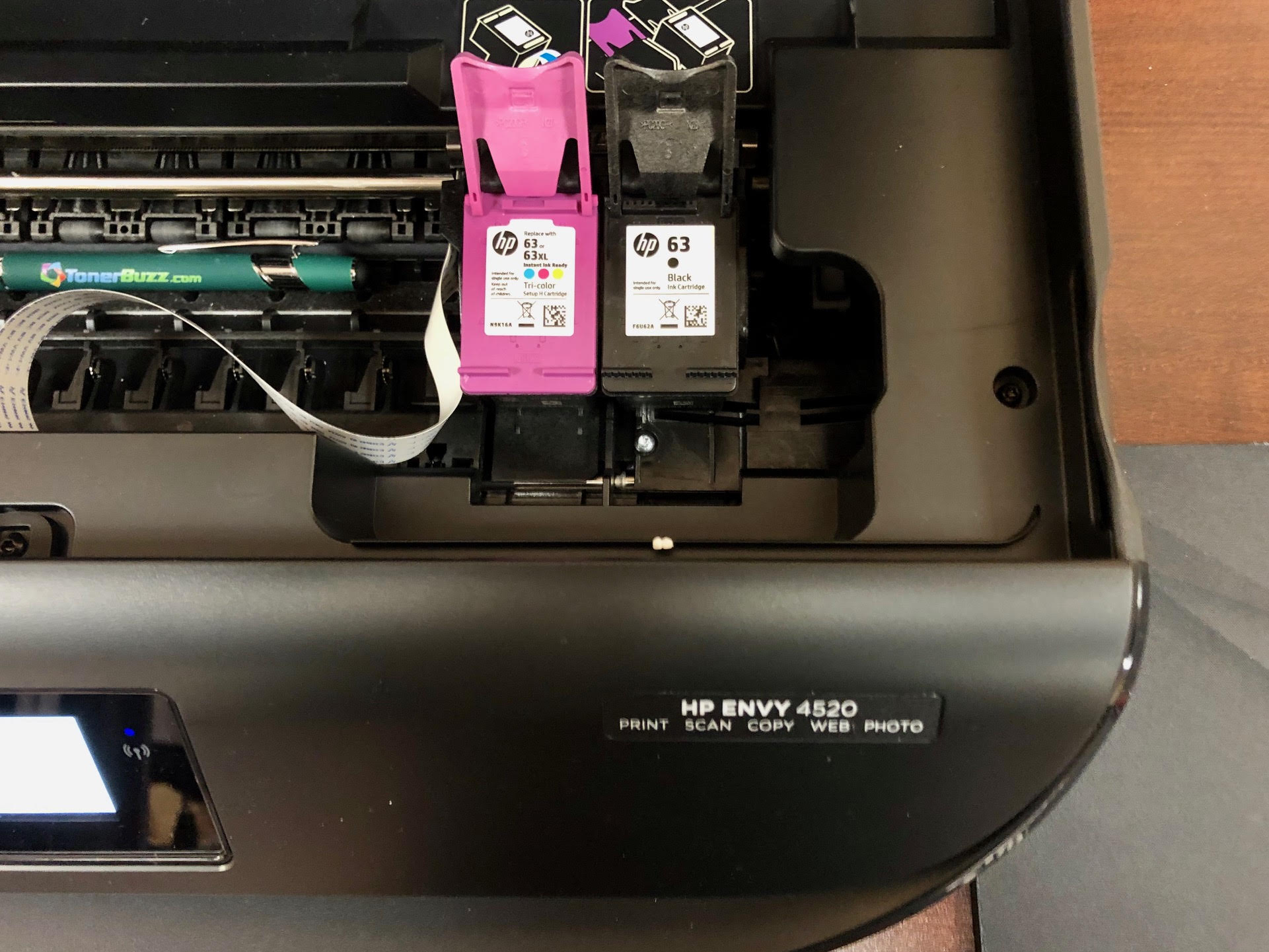

Several companies offer refillable ink cartridges and recycling programs for used cartridges. For instance, HP’s Instant Ink program provides refillable cartridges and recycling services, reducing waste and environmental impact.

Printers with built-in ink tanks, such as Epson’s EcoTank printers, eliminate the need for disposable cartridges, significantly reducing waste and the environmental impact of cartridge production and disposal.

Colorants Used in Printer Ink

Colorants are the pigments or dyes that give printer ink its color. They are available in a wide range of colors, from basic black and white to vibrant hues. The type of colorant used in an ink will affect its properties, such as color strength, lightfastness, and transparency.

Pigments

Pigments are insoluble particles that are suspended in the ink. They are typically made of inorganic materials, such as metal oxides or carbon black. Pigments are very color-stable and resistant to fading, but they can be more expensive than dyes.

Dyes

Dyes are soluble molecules that dissolve in the ink. They are typically made of organic materials, such as azo dyes or anthraquinone dyes. Dyes are less color-stable than pigments, but they are more affordable and can produce a wider range of colors.

Solvents in Printer Ink

Solvents are a crucial component of printer ink, serving as the liquid medium that dissolves and disperses other components, ensuring the ink flows smoothly through the printer nozzle. They play a vital role in determining the ink’s viscosity, drying time, and overall performance.

Types of Solvents in Printer Ink

Different types of solvents are used in printer ink, each with its unique properties:

Water-based solvents

Water is the primary solvent in water-based inks, making them environmentally friendly and non-toxic. They are commonly used in inkjet printers and provide good color vibrancy.

Oil-based solvents

Oil-based solvents, such as mineral oil or vegetable oil, are used in oil-based inks. These inks are water-resistant and produce sharp, detailed prints. They are often used in offset printing and flexography.

Alcohol-based solvents

Alcohol-based solvents, like isopropyl alcohol or ethanol, are used in solvent-based inks. These inks dry quickly and produce durable prints. They are commonly used in screen printing and industrial applications.The choice of solvent depends on the desired properties of the ink, the printing process, and the compatibility with the printer components.

– Elaborate on the specific characteristics of each resin type, such as flexibility, water resistance, and temperature resistance.

Resins are polymers that are used in printer ink to provide flexibility, water resistance, and temperature resistance. The specific characteristics of each resin type vary depending on its chemical composition.

Some of the most common types of resins used in printer ink include:

- Acrylic resinsare known for their flexibility and water resistance. They are often used in inks for outdoor applications, such as billboards and signs.

- Polyester resinsare known for their high temperature resistance. They are often used in inks for industrial applications, such as metal coatings and automotive parts.

- Polyurethane resinsare known for their flexibility and toughness. They are often used in inks for packaging applications, such as food and beverage containers.

The choice of resin affects the overall performance and durability of the printed ink. For example, an ink that is made with an acrylic resin will be more flexible and water-resistant than an ink that is made with a polyester resin.

However, the polyester resin will be more resistant to high temperatures.

Printer ink is a complex mixture of pigments, dyes, resins, and solvents. These components work together to create the vibrant colors and sharp images that we see on printed pages. While the exact composition of printer ink varies depending on the manufacturer, most inks contain a base of water or oil.

The pigments and dyes in the ink provide the color, while the resins and solvents help to bind the ink to the paper and prevent it from smudging. So, if you’re wondering can i print a kindle book , the answer is yes, you can, as long as you have a printer that is compatible with your Kindle device.

The process of printing a Kindle book is similar to printing any other document, and you can use the same type of printer ink that you would use for printing photos or other documents.

The environmental impact of different resins also varies. Some resins, such as acrylic resins, are biodegradable. Others, such as polyester resins, are not. It is important to consider the environmental impact of a resin before using it in a printer ink.

Disposal methods

The disposal methods for resins vary depending on the type of resin. Some resins can be disposed of in landfills, while others must be incinerated. It is important to follow the manufacturer’s instructions for disposing of resins.

Examples of use

Resins are used in a variety of printer ink applications, including:

- Archival prints: Resins are used in archival prints to protect the ink from fading and discoloration. Archival prints are often used in museums and libraries to preserve important documents and artwork.

- Outdoor signage: Resins are used in outdoor signage to protect the ink from the elements. Outdoor signage is often exposed to rain, snow, and sunlight, so it is important to use a resin that is resistant to these conditions.

- Industrial coatings: Resins are used in industrial coatings to protect metal and other surfaces from corrosion and wear. Industrial coatings are often used in manufacturing and construction.

The following table summarizes the key properties and applications of different resin types used in printer ink:

| Resin Type | Key Properties | Applications |

|---|---|---|

| Acrylic | Flexibility, water resistance | Outdoor applications, such as billboards and signs |

| Polyester | High temperature resistance | Industrial applications, such as metal coatings and automotive parts |

| Polyurethane | Flexibility, toughness | Packaging applications, such as food and beverage containers |

Viscosity of Printer Ink

Viscosity is a crucial property of printer ink, influencing its flowability and printability. It measures the resistance of ink to flow and is expressed in units of centipoise (cP) or millipascal-seconds (mPa·s). Optimal viscosity ensures smooth ink flow through the printer’s nozzles, preventing smudging or clogging.

Viscosity is influenced by several factors, including:

Temperature

Viscosity decreases with increasing temperature. As ink heats up during printing, it becomes less viscous, improving its flowability.

Solvent Content

The amount of solvent in ink affects viscosity. Higher solvent content reduces viscosity, making the ink flow more easily.

Resin Concentration

The concentration of resin in ink impacts viscosity. Higher resin concentration increases viscosity, making the ink thicker.

Describe the role of surface tension in printer ink and how it affects the ink’s ability to spread on paper.

Surface tension is a key factor that influences the behavior of printer ink on paper. It refers to the tendency of a liquid’s surface to contract and form a spherical shape, minimizing its surface area. In the context of printer ink, surface tension affects the ink’s ability to spread and adhere to the paper surface.

When the surface tension of an ink is high, it forms a more cohesive unit, resisting spreading and resulting in poor wetting of the paper. This can lead to uneven ink distribution, blotches, and poor image quality. Conversely, a lower surface tension allows the ink to spread more easily, leading to better wetting and sharper images.

Factors Influencing Surface Tension

Several factors influence the surface tension of printer ink, including:

- Surfactant additives:Surfactants are chemicals that reduce surface tension by altering the interactions between the ink and the paper surface. They allow the ink to spread more easily and improve wetting.

- Solvent composition:The composition of the solvents used in the ink can also affect surface tension. Solvents with lower surface tension can reduce the overall surface tension of the ink.

Drying Time of Printer Ink

The drying time of printer ink is a crucial factor that affects the quality and efficiency of printing. Various factors influence the drying time, including ink composition, paper type, temperature, humidity, and air flow. Understanding these factors is essential for optimizing the printing process and achieving desired results.

The drying time of printer ink is primarily determined by the evaporation rate of the solvent. Solvents are volatile liquids that carry the colorants and other components of the ink. As the solvent evaporates, the ink solidifies and adheres to the paper.

The rate of evaporation is influenced by several factors, including:

- Ink composition:The type and concentration of solvents used in the ink affect the evaporation rate. Inks with higher solvent content tend to dry faster than those with lower solvent content.

- Paper type:The porosity and absorbency of the paper play a significant role in the drying time. Porous papers, such as newsprint, absorb the ink more quickly, leading to faster drying times. Non-porous papers, such as coated papers, have a slower absorption rate, resulting in longer drying times.

- Temperature:Higher temperatures accelerate the evaporation process, leading to shorter drying times. Conversely, lower temperatures slow down evaporation, resulting in longer drying times.

- Humidity:High humidity levels in the air can slow down the evaporation process by reducing the vapor pressure gradient between the ink and the air. This can lead to longer drying times.

- Air flow:Good air circulation helps to remove the evaporated solvent from the printing area, facilitating faster drying times. Poor air circulation can trap the evaporated solvent around the printed material, leading to slower drying times.

In addition to evaporation, other mechanisms can also contribute to the drying of printer ink. These include:

- Absorption:Some of the ink components, such as colorants and resins, can be absorbed into the paper fibers. This absorption process can help to solidify the ink and reduce the drying time.

- Oxidation:In the presence of oxygen, some ink components, such as unsaturated oils, can undergo oxidation. This process can lead to the formation of a film on the surface of the ink, which can contribute to faster drying times.

The drying time of printer ink can vary significantly depending on the specific combination of factors involved. For example, a water-based ink on porous paper in a warm, dry environment will typically dry much faster than an oil-based ink on non-porous paper in a cold, humid environment.

Understanding the factors that affect the drying time of printer ink is essential for optimizing the printing process. By controlling these factors, it is possible to achieve desired drying times, improve print quality, and increase productivity.

| Factor | Typical Range |

|---|---|

| Ink composition | Varies depending on the type of ink |

| Paper type | Porous to non-porous |

| Temperature | Room temperature to high temperatures |

| Humidity | Low to high |

| Air flow | Good to poor |

Troubleshooting Tips for Reducing the Drying Time of Printer Ink:

- Use inks with a high solvent content.

- Print on porous paper.

- Print in a warm, dry environment.

- Ensure good air circulation around the printed material.

- Consider using a fan or hair dryer to accelerate the drying process.

By following these tips, it is possible to reduce the drying time of printer ink and improve the efficiency of the printing process.

Color Gamut of Printer Ink

The color gamut of a printer ink refers to the range of colors that it can produce. It is an important factor to consider when choosing an ink for a particular application, as it determines the accuracy and vibrancy of the printed colors.

The color gamut of a printer ink is influenced by several factors, including the number of ink cartridges used, the ink’s color profile, and the type of paper being used.

Number of Ink Cartridges

The number of ink cartridges used in a printer has a significant impact on the color gamut. Printers with more ink cartridges can produce a wider range of colors than printers with fewer cartridges.

For example, a printer with four ink cartridges (cyan, magenta, yellow, and black) can produce a wider range of colors than a printer with only two ink cartridges (black and white).

Ink’s Color Profile

The ink’s color profile is another important factor that influences the color gamut. The color profile is a set of data that defines the colors that the ink can produce.

There are many different color profiles available, each of which is designed for a specific type of paper and printing application.

Type of Paper

The type of paper being used can also affect the color gamut of the printed colors. Different types of paper have different surface textures and absorbency rates, which can affect the way that the ink is absorbed and reflected.

For example, glossy paper will produce more vibrant colors than matte paper.

Shelf Life of Printer Ink

Printer ink has a limited shelf life, which is affected by several factors. Understanding these factors and implementing proper storage practices can help maximize the lifespan and performance of printer ink.

Temperature

Temperature plays a crucial role in the shelf life of printer ink. High temperatures can cause the ink to evaporate and become thick, while low temperatures can make the ink more viscous and difficult to flow. The ideal storage temperature for printer ink is between 59°F (15°C) and 77°F (25°C).

Printer ink is typically composed of a combination of pigments, dyes, solvents, and resins. Pigments are solid particles that provide color, while dyes are soluble and can be dissolved in a solvent. Solvents are used to dissolve the pigments and dyes, and resins are used to bind the pigments and dyes to the paper.

To locate a printer’s IP address, follow the steps outlined in how to find an ip address for a printer. Returning to the composition of printer ink, the specific ingredients used can vary depending on the type of printer and the desired print quality.

Light Exposure

Light exposure can also degrade printer ink. Ultraviolet (UV) rays can break down the ink’s pigments and cause the colors to fade. It is recommended to store printer ink in a cool, dark place, away from direct sunlight.

Air Exposure

Air exposure can lead to the evaporation of solvents in the ink, causing it to become thicker and more difficult to use. Additionally, air can introduce contaminants into the ink, which can affect its performance. To prevent air exposure, keep printer ink cartridges sealed when not in use.

Storage Recommendations

To maximize the shelf life of printer ink, follow these storage recommendations:

- Store printer ink in a cool, dark place, away from direct sunlight.

- Keep printer ink cartridges sealed when not in use.

- Avoid storing printer ink in extreme temperatures, both high and low.

- Use printer ink within the recommended shelf life.

Troubleshooting Printer Ink Issues

Printer ink issues can be frustrating and time-consuming to resolve. However, by understanding the common problems and their solutions, you can quickly get your printer back up and running smoothly.

Common Printer Ink Issues

Some of the most common printer ink issues include:

- Smudging: This occurs when the ink is not properly absorbed by the paper, resulting in a blurred or smeared appearance.

- Fading: This occurs when the ink loses its color over time, resulting in a washed-out or faded appearance.

- Streaking: This occurs when the ink is not evenly distributed across the paper, resulting in lines or streaks of color.

Troubleshooting Tips

To resolve these issues, you can try the following troubleshooting tips:

- Clean the print head: The print head is responsible for delivering the ink to the paper. If the print head is clogged, it can cause smudging, fading, or streaking.

- Adjust the ink settings: The ink settings can affect the quality of the print. If the ink settings are not correct, it can cause smudging, fading, or streaking.

- Replace the ink cartridges: If the ink cartridges are empty or low, it can cause smudging, fading, or streaking.

Emerging Trends and Advancements in Printer Ink Technology

The printing industry is constantly evolving, with new innovations emerging all the time. In the realm of printer ink, several key trends are shaping the future of printing.

One of the most exciting developments is the use of nanotechnology in printer ink. Nanoparticles can be used to create inks with unique properties, such as increased durability, water resistance, and color gamut. This technology has the potential to revolutionize the printing industry, enabling the production of high-quality prints that are resistant to fading and wear.

Sustainable Inks

Another important trend is the development of sustainable inks. Traditional printer inks often contain harmful chemicals that can damage the environment. Sustainable inks are made from renewable resources and are biodegradable, making them much more environmentally friendly.

Personalized Color Matching

Personalized color matching is another emerging trend in printer ink technology. This technology allows users to create custom colors that are perfectly matched to their specific needs. This is a valuable tool for artists, designers, and anyone else who needs to print accurate colors.

User Queries

What are the main components of printer ink?

The main components of printer ink are pigments, dyes, solvents, and resins.

What is the difference between pigment ink and dye ink?

Pigment ink uses insoluble particles for color, while dye ink uses soluble dyes. Pigment ink is more durable and fade-resistant, while dye ink offers a wider color gamut.

What is the role of solvents in printer ink?

Solvents dissolve and disperse the other components of ink, ensuring smooth ink flow and preventing clogging.