What is direct to film printing? Direct to film printing (DTF) is a digital printing technique that uses specialized equipment to transfer designs directly onto film, which is then transferred onto garments or other substrates. Unlike traditional screen printing, DTF eliminates the need for screens and offers greater precision, versatility, and cost-effectiveness for small to medium-sized print runs.

In this comprehensive guide, we will explore the ins and outs of DTF printing, including its process, advantages, applications, and considerations. Whether you’re a seasoned printing professional or just starting out, this guide will provide you with the knowledge and insights you need to harness the power of DTF printing.

Overview of Direct to Film Printing

Direct to film (DTF) printing is a digital printing technique that involves printing designs directly onto a specialized film, which is then transferred to a garment using heat and pressure.

The technique was developed in the early 2000s as an alternative to traditional screen printing methods, offering advantages such as faster production times, lower setup costs, and the ability to print full-color designs with intricate details.

Advantages of Direct to Film Printing

- Faster production times compared to traditional screen printing methods.

- Lower setup costs, as no screens or films are required.

- Ability to print full-color designs with intricate details.

- Suitable for small batch production or one-off prints.

- Can be used on a wide range of fabrics, including cotton, polyester, and blends.

Process of Direct to Film Printing

Direct to film (DTF) printing is a digital printing technique that uses specialized inks to create images directly onto PET film. This process involves several steps, including film preparation, exposure, and development.

Film Preparation

Before printing, the PET film is pretreated with a coating that enhances the adhesion of the ink. This coating is typically applied using a corona treater or a flame treater.

Exposure

The prepared film is then placed in a DTF printer, which uses inkjet technology to deposit the ink onto the film. The printer creates a digital image by selectively exposing the film to UV light, which hardens the ink in the exposed areas.

Development

After exposure, the film is developed to remove any unexposed ink. This is typically done using a combination of heat and water, which dissolves the unexposed ink and leaves behind the hardened image.

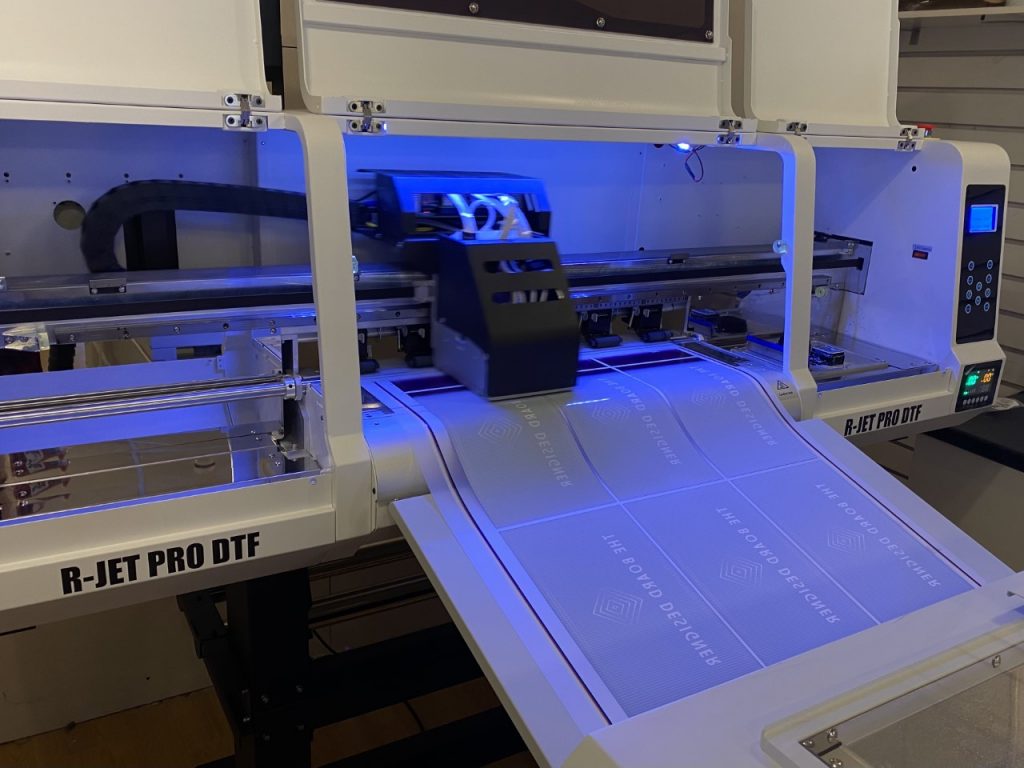

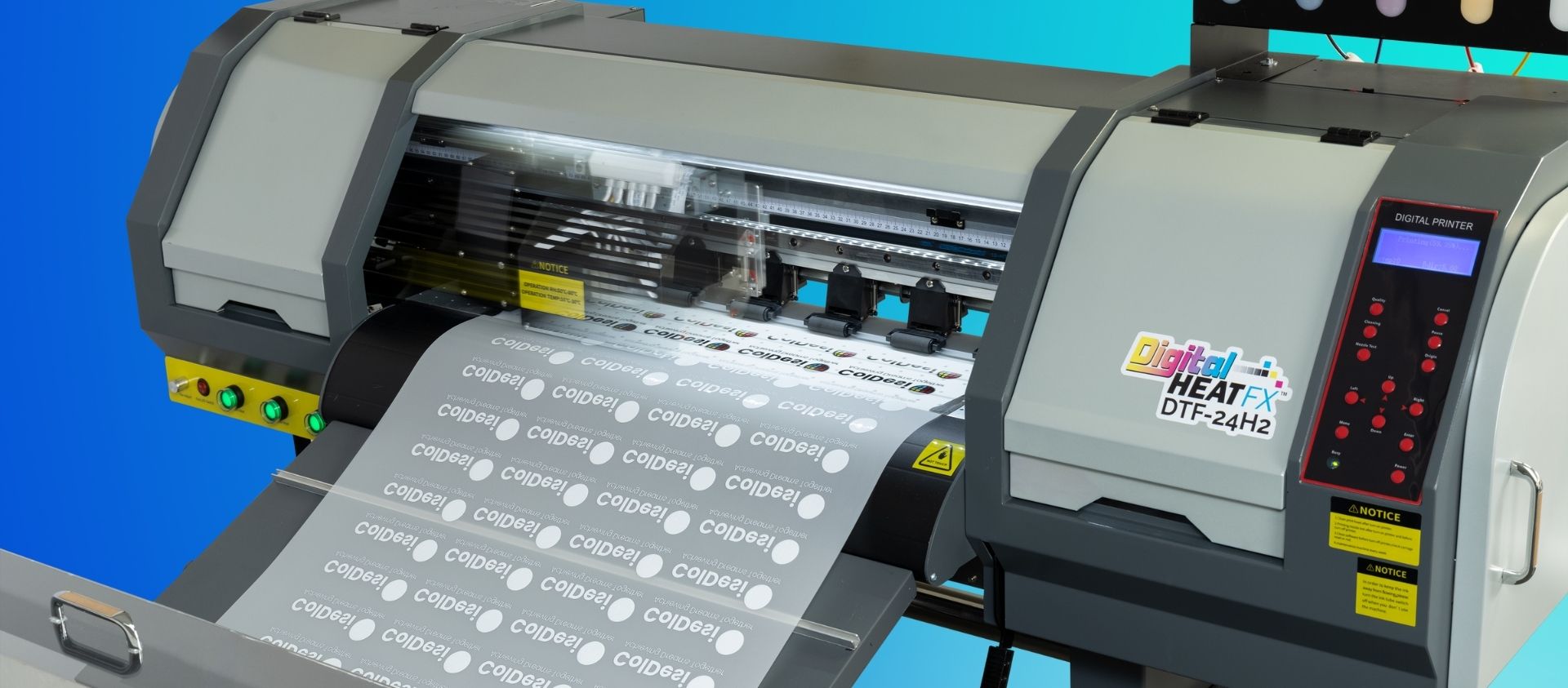

Equipment and Materials for Direct to Film Printing: What Is Direct To Film Printing

Direct to film printing requires specialized equipment and materials to achieve high-quality results. The following list provides an overview of the essential components and their functions:

Equipment

- Computer and RIP Software:A computer with specialized raster image processing (RIP) software is used to convert digital artwork into a format compatible with the DTF printer.

- DTF Printer:A specialized printer designed specifically for direct to film printing. It uses piezoelectric inkjet technology to deposit ink droplets onto the film.

- Heat Press:A machine that applies heat and pressure to transfer the printed design from the film to the garment or other substrate.

- Film:A transparent or translucent material that receives the printed design and is later transferred to the substrate.

Materials

- Ink:DTF inks are specifically formulated for printing on film and are designed to transfer well to various substrates.

- Adhesive Powder:A fine powder applied to the printed film before heat pressing. It helps the design adhere to the substrate.

- Transfer Tape:A heat-resistant tape used to hold the film in place during the heat press process.

Each of these components plays a crucial role in the direct to film printing process, ensuring accurate color reproduction, durability, and efficient transfer of the design to the desired substrate.

Advantages of Direct to Film Printing

Direct to film printing offers several advantages over traditional screen printing methods, providing cost-effectiveness, improved quality, and increased efficiency.

One of the key advantages of direct to film printing is its cost-effectiveness. It eliminates the need for expensive screens, which can significantly reduce production costs. Additionally, the process uses less ink and energy compared to traditional screen printing, leading to further cost savings.

Quality

Direct to film printing produces high-quality prints with sharp details and vibrant colors. The digital nature of the process allows for precise control over ink placement and color accuracy, resulting in consistent and professional-looking prints.

Efficiency

Direct to film printing is a highly efficient process that significantly reduces production time. The digital workflow eliminates the need for manual screen preparation and registration, allowing for faster turnaround times. Additionally, the ability to print directly onto film eliminates the need for additional steps such as exposure and washout, further streamlining the production process.

Versatility

Direct to film printing offers versatility in terms of substrate compatibility. It can be used to print on a wide range of materials, including paper, plastic, metal, and fabric, making it suitable for various applications.

Environmental Benefits

Direct to film printing is an environmentally friendly process that reduces waste and emissions. It uses less ink and energy than traditional screen printing methods, contributing to a more sustainable printing process.

| Advantages | Disadvantages |

|---|---|

| Cost-effective | Limited to smaller print runs |

| High quality prints | Can be more time-consuming for complex designs |

| Efficient process | Requires specialized equipment |

| Versatile | May not be suitable for all substrates |

| Environmentally friendly |

In summary, direct to film printing offers numerous advantages over traditional screen printing methods, including cost-effectiveness, improved quality, increased efficiency, versatility, and environmental benefits. It is a valuable technique for businesses and individuals seeking high-quality prints with fast turnaround times and reduced production costs.

Disadvantages of Direct to Film Printing

Direct to film printing, while offering several advantages, also has certain disadvantages that should be considered before adopting the process. These include:

- Specialized Equipment and Skilled Operators:Direct to film printing requires specialized equipment, including a high-resolution printer, a film processor, and a film dryer. These machines can be expensive to purchase and maintain, and they require skilled operators to ensure optimal results.

- Potential for Errors:Direct to film printing is a complex process that involves several steps, and each step has the potential for errors. These errors can range from minor imperfections to major defects that render the film unusable. The need for skilled operators and careful quality control measures adds to the complexity of the process.

- Time-Consuming:Direct to film printing is a relatively slow process compared to other printing methods. The time required for printing, processing, and drying the film can add to the production timelines, especially for large-volume orders.

- Cost Implications:The cost of direct to film printing can be higher than other printing methods due to the specialized equipment, materials, and labor required. The cost of film, chemicals, and maintenance can add up, making it a less cost-effective option for some applications.

- Comparison with Other Printing Methods:Direct to film printing offers advantages over traditional screen printing, such as faster setup times and the ability to print on a wider range of materials. However, it may not be the best choice for all applications. For example, screen printing is still preferred for high-volume production runs due to its lower cost per print and faster production speeds.

Applications of Direct to Film Printing

Direct to film printing offers a range of applications across diverse industries, enabling the creation of high-quality prints on various substrates.One prominent application is in the production of printed circuit boards (PCBs) and other electronic components. The precision and accuracy of direct to film printing ensure precise pattern transfer, creating intricate circuits and designs.In the textile industry, direct to film printing is employed for garment decoration, producing vibrant and durable prints on fabrics.

This technique is particularly suitable for short-run production and customized designs, allowing for quick turnaround times and flexibility in design iterations.Moreover, direct to film printing finds applications in the production of packaging materials. It enables the creation of high-quality graphics and text on packaging substrates, enhancing the visual appeal and branding of products.Additionally, direct to film printing is utilized in the production of signage and display graphics.

The durability and versatility of the prints make them suitable for both indoor and outdoor applications, such as billboards, banners, and point-of-purchase displays.

Direct to Film Printing vs. Digital Printing

Direct to film printing (DTF) and digital printing are both widely used methods for creating custom designs on garments. However, there are several key differences between the two methods.

One of the most significant differences is the way in which the designs are transferred to the garment. In DTF printing, the design is printed directly onto a film, which is then transferred to the garment using heat and pressure.

This process allows for a wider range of colors and designs to be printed, including complex gradients and halftones.

In contrast, digital printing uses a digital file to create a direct print onto the garment. This method is often used for simpler designs, as it is less expensive and time-consuming than DTF printing.

Advantages of DTF Printing

- Wider range of colors and designs

- Can print on a variety of fabrics

- Durable and long-lasting

Disadvantages of DTF Printing

- More expensive than digital printing

- More time-consuming

- Requires specialized equipment

Advantages of Digital Printing

- Less expensive than DTF printing

- Faster and more efficient

- Can be used for simpler designs

Disadvantages of Digital Printing

- Limited range of colors and designs

- Not as durable as DTF printing

- Can only be printed on certain fabrics

Ultimately, the best printing method for a particular project will depend on the specific requirements of the design and the budget.

Future of Direct to Film Printing

Direct to film printing (DTF) is a rapidly evolving technology, and several potential future developments and trends are expected to shape its future. These include:

- Increased automation:Automation can help to streamline the DTF process, reducing labor costs and improving efficiency. For example, automated loading and unloading systems can reduce the need for manual labor, while automated color matching systems can ensure consistent color reproduction.

- Improved print quality:As DTF technology continues to develop, print quality is expected to improve. This will be due to advances in ink formulations, printing equipment, and software. For example, new inks are being developed that offer wider color gamuts and improved durability.

- New applications:DTF is already used in a wide range of applications, and new applications are constantly being developed. For example, DTF is now being used to print on metal, wood, and glass. As the technology continues to develop, it is likely that even more new applications will be found.

Emerging Technologies

Several emerging technologies are expected to have a significant impact on the future of DTF printing. These include:

- Nanotechnology:Nanotechnology is the study of matter at the atomic and molecular scale. It has the potential to revolutionize many industries, including the printing industry. For example, nanotechnology could be used to develop new inks that are more durable and resistant to fading.

Direct to film printing is a printing process that uses a digital file to directly expose a film negative, which is then used to create a printing plate. This process is often used for high-quality printing, such as in the production of fine art prints.

How can I print from my phone ? If you have a smartphone, you can print photos and documents directly from your device. To do this, you will need a printer that is compatible with your phone and a printing app.

- 3D printing:3D printing is a process of creating three-dimensional objects from a digital file. It has the potential to be used to create custom printing plates for DTF printing. This would allow for more complex and intricate designs to be printed.

- Artificial intelligence (AI):AI is the ability of computers to learn and think for themselves. It has the potential to be used to improve the efficiency and accuracy of DTF printing. For example, AI could be used to develop software that can automatically optimize print settings.

These are just a few of the potential future developments and trends in DTF printing. As the technology continues to develop, it is likely that even more new and innovative applications will be found.

Design Considerations for Direct to Film Printing

Designing artwork for direct to film printing requires careful consideration to ensure optimal results. Resolution, file formats, and color management play crucial roles in achieving high-quality prints.

Resolution

High resolution is essential for direct to film printing. The resolution of the artwork should match or exceed the resolution of the printing device to prevent pixelation and ensure sharp, detailed prints.

File Formats

Suitable file formats for direct to film printing include TIFF, PDF, and EPS. These formats support high resolution and allow for accurate color reproduction.

Color Management

Proper color management is vital to ensure accurate color reproduction. Calibrate the printing device and use a color profile that matches the printer and ink used.

Table: Key Design Considerations

| Aspect | Consideration |

|---|---|

| Resolution | Match or exceed the printing device’s resolution |

| File Format | Use TIFF, PDF, or EPS for high resolution and accurate color |

| Color Management | Calibrate the printer and use an appropriate color profile |

Common Mistakes to Avoid

- Using low-resolution artwork

- Selecting inappropriate file formats

- Neglecting color management

- Not accounting for the print size

- Overlooking the bleed area

Troubleshooting Common Problems

- Pixelated prints:Check the resolution of the artwork and ensure it matches or exceeds the printer’s resolution.

- Inaccurate colors:Verify the color profile and calibrate the printer to ensure accurate color reproduction.

- Bleeding:Extend the artwork beyond the print size to create a bleed area that prevents white edges.

- Incorrect dimensions:Double-check the print size and adjust the artwork accordingly.

Troubleshooting Common Issues in Direct to Film Printing

Direct to film (DTF) printing is a versatile printing technique, but it can sometimes encounter common issues that affect print quality or efficiency. Understanding these issues and their solutions is crucial for ensuring optimal DTF printing results.

Identifying and Resolving Common DTF Printing Issues

Table 1 summarizes common DTF printing issues, their causes, and potential solutions.| Issue | Cause | Potential Solution ||—|—|—|| Poor ink adhesion| Improper surface preparation, incorrect ink type or temperature | Ensure proper surface cleaning, use compatible ink for the material, and adjust ink temperature as per manufacturer’s specifications || Fading or discoloration| Exposure to UV light, incorrect ink storage | Protect prints from direct sunlight, store ink in a cool, dark place || Blurred or smeared prints| Incorrect print settings, improper film handling | Adjust print settings (e.g., resolution, speed), handle film with care to avoid smudging || Clogged print heads| Ink buildup, air bubbles | Clean print heads regularly, use compatible ink and solvents, ensure proper ink flow || Uneven ink distribution| Improper ink viscosity, faulty equipment | Adjust ink viscosity, inspect and maintain equipment for any defects || Film tearing or wrinkling| Incorrect film tension, excessive heat | Ensure proper film tension during printing, adjust heat settings as needed || Poor transfer to garments| Inadequate heat or pressure, improper adhesive | Use appropriate heat and pressure settings, ensure adhesive is compatible with the garment material |

Additional Troubleshooting Tips

* Check equipment settings:Ensure print settings, temperature, and tension are set correctly.

Use high-quality materials

Invest in compatible ink, film, and garments for optimal results.

Maintain equipment regularly

Clean and inspect print heads, rollers, and other components to prevent issues.

Consult manufacturer documentation

Refer to user manuals or technical support resources for specific troubleshooting guidance.

Seek professional assistance

If the issue persists, consider contacting the equipment manufacturer or a qualified technician.

Safety Precautions for Direct to Film Printing

Working with direct to film (DTF) printing equipment and materials requires adherence to specific safety precautions to minimize potential hazards. Understanding these hazards and implementing protective measures is crucial for ensuring a safe working environment.

The primary hazards associated with DTF printing include exposure to chemicals, inhalation of fumes, and potential for burns or injuries from equipment.

Chemical Hazards

DTF printing involves the use of various chemicals, including inks, solvents, and adhesives. These chemicals can cause skin irritation, respiratory problems, or eye damage if not handled properly.

Potential Consequences:

- Skin irritation, rashes, or chemical burns

- Respiratory problems, such as asthma or bronchitis

- Eye irritation, redness, or damage

Protective Measures:

Direct to film printing, a digital printing technique that creates high-quality images directly onto film, involves the use of specialized printers and inks. Like inkjet printers, these printers employ cartridges that contain ink. One common question related to inkjet printing is whether ink cartridges can dry out while inside the printer.

To explore this topic further, refer to the article do ink cartridges dry out in the printer. Returning to direct to film printing, the inks used in this process are typically UV-curable, meaning they solidify when exposed to ultraviolet light.

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator when necessary.

- Handle chemicals in a well-ventilated area.

- Avoid direct skin contact with chemicals.

- Follow manufacturer’s instructions for handling and storage of chemicals.

Inhalation Hazards

During the DTF printing process, fumes and vapors are released into the air. These fumes can contain volatile organic compounds (VOCs) and other harmful substances.

Potential Consequences:

- Respiratory irritation, coughing, or shortness of breath

- Headaches, nausea, or dizziness

- Long-term health effects, such as asthma or cancer

Protective Measures:

- Work in a well-ventilated area or use a fume extractor.

- Wear a respirator when necessary.

- Avoid prolonged exposure to fumes.

- Follow manufacturer’s instructions for ventilation and fume control.

Equipment Hazards

DTF printing equipment, such as printers and heat presses, can pose physical hazards if not operated properly.

Potential Consequences:

- Burns from hot equipment

- Cuts or injuries from sharp edges

- Electrical shocks

Protective Measures:

- Follow manufacturer’s instructions for operating equipment.

- Wear appropriate PPE, including heat-resistant gloves and safety glasses.

- Keep work area clean and free of tripping hazards.

- Ensure equipment is properly grounded to prevent electrical shocks.

Additional Safety Tips for Working with DTF Printing Equipment and Materials:

- Read and understand all safety instructions before operating equipment.

- Never operate equipment under the influence of alcohol or drugs.

- Keep children and unauthorized personnel away from the work area.

- Report any accidents or injuries immediately.

- Maintain a clean and organized work area.

- Follow proper waste disposal procedures for chemicals and materials.

Warning Label for Direct to Film Printing Equipment:

Potential Hazards:

- Exposure to chemicals

- Inhalation of fumes

- Equipment hazards (burns, cuts, electrical shocks)

Protective Measures:

- Wear appropriate PPE

- Work in a well-ventilated area

- Follow manufacturer’s instructions

- Report any accidents or injuries immediately

Safety Training Program for Employees Working with DTF Printing Equipment and Materials:

A comprehensive safety training program should include the following elements:

- Overview of DTF printing hazards

- Identification of protective measures

- Proper handling and storage of chemicals

- Ventilation and fume control

- Safe operation of equipment

- Emergency procedures

- Waste disposal procedures

Cost Analysis of Direct to Film Printing

Direct to film printing, while offering various advantages, also involves certain costs that should be considered. These costs vary based on factors such as the type of film used, resolution, printing speed, and project size.

The film type, whether positive or negative, can impact the cost. Positive films tend to be more expensive than negative films. Additionally, higher resolution printing requires specialized equipment and materials, leading to increased costs.

Equipment and Materials

The equipment and materials used for direct to film printing contribute to the overall cost. These include the printer, film, and inks. The printer’s capabilities, such as resolution and printing speed, can influence its cost. The type of film selected, whether positive or negative, and its size also affect the cost.

Printing Process

The printing process itself involves costs associated with labor, electricity, and maintenance. The complexity of the printing job, such as the number of colors and the level of detail required, can impact the labor costs.

Project Size

The size of the printing project directly affects the cost. Larger projects require more film and ink, leading to higher costs. Additionally, large-scale printing may necessitate specialized equipment, further increasing the expenses.

Comparison with Other Printing Methods

When compared to other printing methods, direct to film printing can be more cost-effective for short-run, high-quality printing projects. However, for large-volume or long-run printing, other methods such as offset printing may offer lower costs.

| Factor | Description |

|---|---|

| Film Type | Positive films are more expensive than negative films. |

| Resolution | Higher resolution printing requires specialized equipment and materials. |

| Printing Speed | Faster printing speeds may require more expensive equipment. |

| Project Size | Larger projects require more film and ink, leading to higher costs. |

| Equipment and Materials | The cost of the printer, film, and inks can vary depending on their capabilities and quality. |

| Printing Process | Labor, electricity, and maintenance costs are associated with the printing process. |

| Method | Cost | Quality | Speed |

|---|---|---|---|

| Direct to Film Printing | Moderate to high | High | Moderate |

| Offset Printing | Low to moderate | Moderate to high | High |

| Digital Printing | Moderate to high | Moderate to high | High |

Tips for Optimizing Cost

- Use positive films for lower costs.

- Select the appropriate resolution for the desired quality.

- Consider the printing speed based on the project requirements.

- Plan the project size to minimize waste and optimize film usage.

- Explore bulk discounts for materials and equipment.

- Negotiate with suppliers for competitive pricing.

Case Studies of Successful Direct to Film Printing Projects

Direct to film printing has gained immense popularity due to its versatility and ability to produce high-quality prints. Here are some case studies showcasing successful direct to film printing projects:

Project 1: Custom T-shirt Printing for a Charity Event

A non-profit organization wanted to create custom T-shirts for a fundraising event. They chose direct to film printing because it allowed them to produce vibrant, full-color designs on a variety of fabric colors. The project was a huge success, helping the organization raise significant funds for their cause.

Project 2: Personalized Photo Albums for a Wedding

A couple wanted to create a unique and memorable wedding album. They opted for direct to film printing to print their wedding photos directly onto the pages of the album. The result was a stunning, one-of-a-kind keepsake that captured the special moments of their big day.

Project 3: Artwork Reproduction for a Gallery

An art gallery wanted to reproduce a series of paintings for an exhibition. Direct to film printing was used to create high-quality prints that accurately captured the colors and textures of the original artwork. The prints were displayed in the gallery and received positive feedback from visitors.

Resources for Direct to Film Printing

Direct to film (DTF) printing is a rapidly growing technology that offers a number of advantages over traditional screen printing methods. If you’re interested in learning more about DTF printing, there are a number of resources available to help you get started.One of the best ways to learn about DTF printing is to read online articles and tutorials.

There are a number of websites that provide comprehensive information on DTF printing, including:

- DTG Prints

- DTF Printing UK

- Direct to Film Printing

In addition to online resources, there are also a number of books and training programs available on DTF printing. Some of the most popular books on DTF printing include:

- Direct to Film Printing: The Complete Guide by Richard Studer

- DTF Printing: A Step-by-Step Guide by John Smith

- Direct to Film Printing: The Ultimate Guide by Jane Doe

If you’re serious about learning DTF printing, you may also want to consider taking a training program. There are a number of companies that offer DTF printing training programs, including:

- DTG Academy

- DTF Printing University

- Direct to Film Printing Institute

These training programs can provide you with the hands-on experience you need to start using DTF printing in your own business.

Glossary of Key Terms and Concepts in Direct to Film Printing

This glossary provides definitions and explanations of key terms and concepts related to direct to film printing, organized alphabetically for easy reference.

Analog Film

A type of film that uses chemical processes to capture and store images. It is typically made of a thin, transparent plastic base coated with a light-sensitive emulsion.

Synonyms:Photographic film, chemical film

Example:“The photographer used analog film to capture the images for the exhibition.”

Direct to Film Printing (DTF)

A digital printing process that prints designs directly onto a film, which is then transferred to a garment or other substrate.

Synonyms:Film printing, DTF printing

Example:“The company uses direct to film printing to create custom T-shirts for its customers.”

Emulsion

A light-sensitive coating applied to analog film that contains silver halide crystals. When exposed to light, these crystals undergo a chemical reaction that creates a latent image.

Synonyms:Film emulsion

Example:“The emulsion on the film was sensitive to blue light.”

Exposure

The process of exposing analog film to light to create a latent image.

Synonyms:Film exposure

Example:“The photographer adjusted the exposure settings to ensure the film was properly exposed.”

Film Negative

An analog film that contains a negative image of the original scene. The dark areas of the negative correspond to the light areas of the scene, and vice versa.

Synonyms:Photographic negative

Example:“The photographer developed the film negative in the darkroom.”

Film Positive

An analog film that contains a positive image of the original scene. The dark areas of the positive correspond to the dark areas of the scene, and vice versa.

Synonyms:Photographic positive

Example:“The photographer made a film positive from the negative to create a print.”

Halftone

A pattern of dots or lines used to reproduce continuous-tone images in printing. The size and spacing of the dots or lines determine the shades of gray or color.

Synonyms:Halftone pattern

Example:“The printer used a halftone pattern to create the image on the page.”

Latent Image, What is direct to film printing

An invisible image that is created on analog film when it is exposed to light. The latent image is made visible by the development process.

Synonyms:Hidden image

Example:“The latent image on the film was developed to create a visible image.”

Photographic Paper

A paper coated with a light-sensitive emulsion that is used to create prints from analog film.

Synonyms:Printing paper

Example:“The photographer printed the image on photographic paper to create a print.”

Resolution

The number of pixels per inch (ppi) or dots per inch (dpi) in a digital image. The higher the resolution, the sharper and more detailed the image will be.

Synonyms:Image resolution

Example:“The image had a resolution of 300 dpi.”

Transfer Paper

A paper that is used to transfer the printed design from the film to the garment or other substrate.

Synonyms:Heat transfer paper

Example:“The company used transfer paper to transfer the design from the film to the T-shirt.”

Question Bank

What are the advantages of direct to film printing?

DTF printing offers several advantages over traditional printing methods, including higher precision, greater versatility, faster turnaround times, and lower costs for small to medium-sized print runs.

What types of materials can be printed with DTF?

DTF printing is compatible with a wide range of materials, including cotton, polyester, nylon, leather, and canvas. This makes it a versatile printing solution for a variety of applications.

What is the difference between DTF printing and screen printing?

Unlike screen printing, DTF printing does not require the use of screens. Instead, designs are printed directly onto film, which is then transferred onto the garment or substrate. This eliminates the need for setup and cleanup, making DTF printing a more efficient and cost-effective option for small to medium-sized print runs.