What is a printer fuser? It’s a crucial component in any printer, responsible for the final step of the printing process: fusing toner to paper, making your prints permanent and ready to use. This comprehensive guide will delve into the intricacies of printer fusers, exploring their operation, types, maintenance, troubleshooting, and environmental impact.

In this guide, we’ll take a closer look at the different types of fusers, their advantages and disadvantages, and how to maintain and troubleshoot common fuser issues. We’ll also discuss the environmental considerations associated with fusers and provide tips for proper disposal.

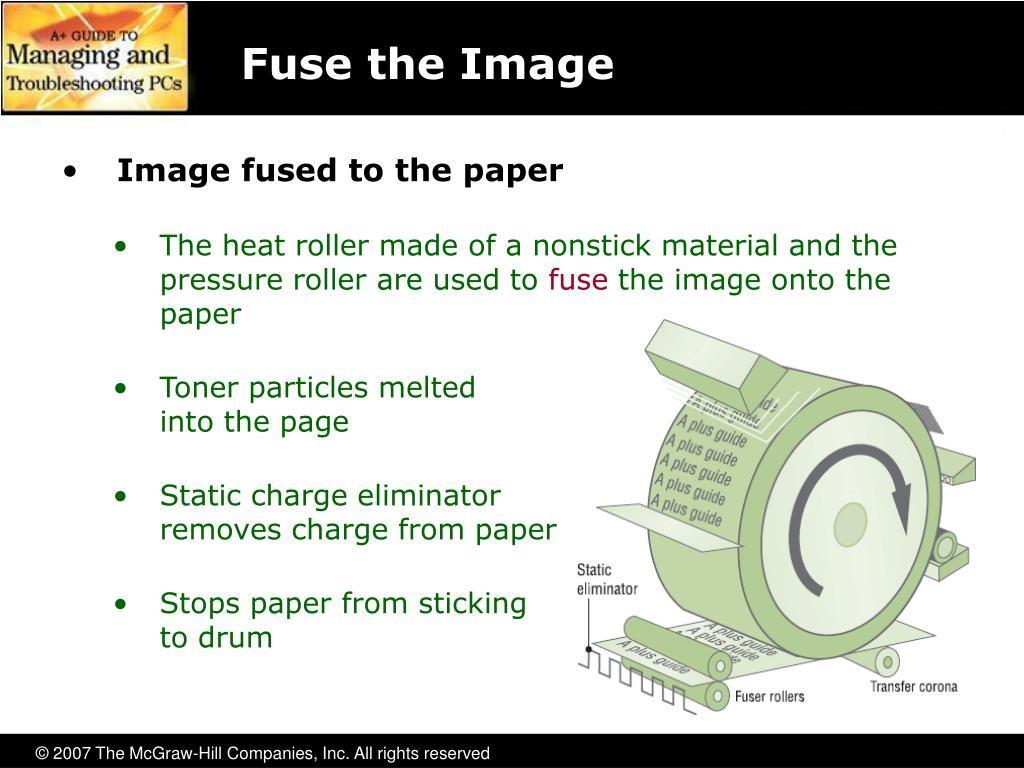

Provide a diagram or illustration of a fuser assembly, labeling the key components.

A fuser assembly is a critical component of a laser printer that bonds toner to paper. It consists of several key components that work together to apply heat and pressure to the toner, causing it to melt and adhere to the paper.

A printer fuser is a crucial component that bonds toner to paper during the printing process. Its primary function is to heat and press the toner onto the page, ensuring a permanent and durable print. If you encounter issues with your printer, it may be necessary to determine its IP address for troubleshooting purposes.

You can find the IP address by accessing the printer’s settings or utilizing online tools. For a detailed guide on how to find your printer’s IP address, refer to this comprehensive resource: how do you find ip address of printer.

Understanding the role of the printer fuser and its importance in the printing process can help you maintain and troubleshoot your printer effectively.

Here is a diagram of a typical fuser assembly, with the key components labeled:

- Fuser roller:A heated roller that melts the toner.

- Pressure roller:A roller that applies pressure to the paper, pressing it against the fuser roller.

- Thermistor:A sensor that measures the temperature of the fuser roller.

- Fuser lamp:A light source that helps to heat the fuser roller.

- Fuser drive motor:A motor that rotates the fuser roller.

Operation of a Printer Fuser

Purpose and Location of the Fuser

The fuser, also known as a fusing unit, is a crucial component in the printing process. Its primary purpose is to permanently bond the toner particles to the paper, creating a durable and legible print. The fuser is typically located towards the end of the printer’s paper path, after the toner has been transferred to the paper from the imaging drum.

Stages of the Printing Process Involving the Fuser

The fuser is involved in the final stages of the printing process, which typically includes the following steps:

- Imaging:The printer creates an electrostatic image of the document on the imaging drum.

- Toner Transfer:The toner particles are attracted to the charged areas on the imaging drum and transferred to the paper.

- Fusing:The fuser applies heat and pressure to the toner particles, fusing them to the paper.

- Cooling:The fused toner is cooled down to prevent smudging or smearing.

Heating and Pressure Mechanisms

The fuser uses a combination of heat and pressure to fuse the toner particles to the paper. The heating element, typically a metal roller or lamp, generates heat that melts the toner particles. The pressure roller, made of a durable material like rubber or silicone, applies pressure to the heated toner, pressing it into the paper fibers and creating a permanent bond.

Factors Affecting the Fusing Process

Several factors can impact the quality of the fusing process, including:

- Paper Type:Different types of paper have varying heat resistance, which can affect the fusing temperature and pressure required.

- Toner Type:Different toner formulations may have different melting points, requiring adjustments in the fuser temperature.

- Environmental Conditions:Humidity and temperature can influence the fusing process, affecting the adhesion of the toner to the paper.

Fuser Temperature Control

The fuser temperature is precisely controlled to ensure optimal fusing without damaging the paper or toner. Most fusers have a built-in temperature sensor that monitors the temperature and adjusts the heating element accordingly. Additionally, some fusers have multiple temperature settings to accommodate different paper types and toner formulations.

Safety Mechanisms

Printer fusers incorporate various safety mechanisms to prevent overheating or damage to the printer or user. These mechanisms may include:

- Thermal Fuses:Thermal fuses are designed to blow if the fuser temperature exceeds a safe limit, disconnecting power to the heating element.

- Overheating Sensors:Overheating sensors detect excessive temperatures and trigger an alarm or shut down the printer to prevent damage.

- Paper Jam Detection:Paper jam sensors can detect when paper is stuck in the fuser, preventing damage to the fuser or printer.

Types of Printer Fusers

Printer fusers come in various types, each with unique technologies and designs. The primary categories of fusers are:

- Heat Roller Fusers

- Film Fusers

- Pressure Roller Fusers

- Nipper Roller Fusers

Heat Roller Fusers

Heat roller fusers utilize two heated rollers to fuse toner particles onto paper. The rollers rotate in opposite directions, pressing the paper between them and melting the toner. Heat roller fusers are known for their cost-effectiveness and efficiency.

Film Fusers

Film fusers employ a heated film to melt toner onto paper. The film transfers heat to the toner, creating a permanent bond with the paper. Film fusers offer high-quality prints and are durable, but they are more expensive than heat roller fusers.

Pressure Roller Fusers

Pressure roller fusers use pressure and heat to fuse toner onto paper. A heated roller presses the paper against a pressure roller, melting the toner and creating a bond. Pressure roller fusers are commonly found in low-end printers due to their low cost.

A printer fuser is a device that uses heat and pressure to bond toner particles to paper in a laser printer. The fuser roller is heated to a high temperature, and the paper is passed between the fuser roller and a pressure roller.

This process causes the toner particles to melt and adhere to the paper. A street prints wallpaper is a type of street art that uses a printer to create designs on walls and other surfaces. The printer fuser is an essential part of this process, as it is responsible for bonding the toner particles to the surface.

Nipper Roller Fusers

Nipper roller fusers combine pressure and heat to fuse toner onto paper. A heated roller presses the paper against a nipper roller, which applies additional pressure. Nipper roller fusers offer high-quality prints and are durable, but they are more expensive than other types of fusers.

| Type | Cost | Efficiency | Durability | Print Quality |

|---|---|---|---|---|

| Heat Roller Fusers | Low | High | Moderate | Good |

| Film Fusers | High | High | High | Excellent |

| Pressure Roller Fusers | Low | Low | Low | Poor |

| Nipper Roller Fusers | High | High | High | Excellent |

The most common type of fuser used in modern printers is the heat roller fuser due to its cost-effectiveness, efficiency, and overall reliability.

Maintenance and Troubleshooting

Maintaining printer fusers is crucial to ensure optimal performance and longevity. Regular cleaning and lubrication are essential, and addressing common issues promptly can prevent costly repairs.

Routine Maintenance Procedures

Routine maintenance involves cleaning the fuser assembly and applying lubricant to designated points. Cleaning removes dust, paper particles, and toner residue that can accumulate over time. Lubrication reduces friction and wear, extending the life of moving parts.

- Cleaning:Use a soft, lint-free cloth or compressed air to remove debris from the fuser rollers, pressure roller, and surrounding areas.

- Lubrication:Apply a thin layer of high-temperature lubricant to the bearings, gears, and other moving parts as per the manufacturer’s instructions.

Common Fuser Issues and Troubleshooting

Common fuser issues include error codes, paper jams, and image quality problems. Error codes indicate specific problems, and their meanings can be found in the printer’s manual. Paper jams can occur due to worn rollers, misaligned fusers, or foreign objects.

Image quality issues, such as ghosting or fading, may be caused by uneven heat distribution or dirty fuser rollers.

Troubleshooting involves identifying the issue, determining its cause, and implementing the appropriate solution.

Troubleshooting Flowchart

A troubleshooting flowchart can assist in diagnosing and resolving fuser issues. It provides a step-by-step guide, eliminating potential causes and leading to the most likely solution.

Flowchart Steps:

- Check for error codes and consult the printer’s manual.

- Inspect for paper jams and remove any obstructions.

- Examine the fuser assembly for damage or misalignment.

- Clean the fuser rollers and pressure roller.

- Lubricate moving parts as per the manufacturer’s instructions.

- Reset the printer and try printing again.

Common Fuser Issues, Symptoms, and Solutions

The following table summarizes common fuser issues, their symptoms, and recommended solutions:

| Issue | Symptoms | Solution |

|---|---|---|

| Error Code | Printer displays an error code | Refer to the printer’s manual for the specific error code’s meaning |

| Paper Jam | Paper is stuck in the fuser area | Remove jammed paper and check for obstructions |

| Ghosting or Fading | Printed images appear faint or have ghosting | Clean fuser rollers or adjust fuser temperature |

| Wrinkled or Melted Paper | Paper becomes wrinkled or melted during printing | Check fuser temperature or replace worn rollers |

| Uneven Fusing | Parts of the printed page are not fused properly | Clean fuser rollers or adjust fuser pressure |

Video Demonstrations or Animated GIFs

Video demonstrations or animated GIFs can provide visual guidance for maintenance and troubleshooting procedures. They can illustrate cleaning techniques, lubrication points, and how to resolve common issues.

Safety Considerations

Printer fusers are essential components in laser printers, but they also pose potential hazards that must be addressed for safe handling and servicing.

The primary hazard associated with fusers is their high operating temperature. During normal operation, fusers can reach temperatures up to 350 degrees Celsius (662 degrees Fahrenheit), which can cause burns or fires if mishandled.

Electrical Hazards

- Fusers operate on high-voltage electricity, which can cause electrical shocks or electrocution if proper precautions are not taken.

- Always unplug the printer before servicing the fuser or any other electrical components.

- Wear insulated gloves and use insulated tools when working on the fuser.

Heat Hazards

- Fusers generate high heat, which can cause burns or fires if mishandled.

- Allow the fuser to cool down completely before touching it or performing any maintenance.

- Keep flammable materials away from the printer while it is in operation.

Fumes and Emissions

- Fusers can emit fumes and gases during operation, which can be harmful if inhaled.

- Ensure proper ventilation in the area where the printer is located.

- Do not breathe in the fumes directly.

Environmental Impact

Printer fusers can have a significant environmental impact due to the materials used in their construction and the energy they consume during operation. The disposal of fusers also poses environmental challenges.

Fusers typically contain a variety of materials, including metals, plastics, and ceramics. These materials can be harmful to the environment if not disposed of properly. For example, metals can leach into groundwater and contaminate soil, while plastics can take hundreds of years to decompose.

Eco-Friendly Practices and Regulations

- Many countries have regulations in place to govern the disposal of fusers and other electronic waste. These regulations typically require that fusers be recycled or disposed of in a manner that minimizes their environmental impact.

- Some manufacturers offer recycling programs for fusers. These programs allow users to return their old fusers to the manufacturer for proper disposal.

- Users can also choose to purchase fusers that are made from recycled materials. This helps to reduce the demand for new materials and the environmental impact of fuser production.

Best Practices for Reducing Environmental Impact

- Recycle fusers whenever possible.

- Dispose of fusers in accordance with local regulations.

- Purchase fusers that are made from recycled materials.

- Use fusers that are energy-efficient.

- Turn off fusers when not in use.

By following these best practices, users can help to reduce the environmental impact of printer fusers.

History and Evolution

The history of printer fuser technology can be traced back to the early days of printing itself. The first fusers were simple devices that used heat to bond toner particles to paper. Over time, fusers have evolved to become more efficient and reliable, and they now play a critical role in the printing process.

One of the most significant advancements in fuser technology was the development of the heated roller fuser. This type of fuser uses a heated roller to melt the toner particles and bond them to the paper. Heated roller fusers are more efficient than older fuser designs, and they produce higher-quality prints.

Another important advancement in fuser technology was the development of the film fuser. Film fusers use a thin film of heated plastic to melt the toner particles and bond them to the paper. Film fusers are even more efficient than heated roller fusers, and they produce even higher-quality prints.

Today, fusers are an essential part of the printing process. They play a critical role in producing high-quality prints that are durable and long-lasting.

Key Innovations

- Development of the heated roller fuser

- Development of the film fuser

- Introduction of new materials and coatings

- Improved temperature control

- Increased efficiency and reliability

Comparison to Other Printer Components

A printer fuser is an integral part of a laser printer system, working in conjunction with other key components such as the toner cartridge and imaging drum to produce high-quality printed documents.

The toner cartridge contains fine particles of toner powder, which are electrostatically charged and transferred to the imaging drum. The imaging drum is then exposed to a laser beam, which creates an electrostatic image of the document on its surface.

The fuser assembly, located at the end of the printing process, plays a crucial role in fusing the toner particles to the paper. It consists of two heated rollers that press the paper between them, applying heat and pressure to bond the toner particles permanently to the paper fibers.

The fuser works in coordination with the toner cartridge and imaging drum to ensure that the printed image is clear, crisp, and resistant to smudging or fading. Without the fuser, the toner particles would remain loose on the paper, resulting in poor print quality.

Case Studies and Applications

Printer fusers play a vital role in various industries, enabling efficient and high-quality printing for diverse applications.

Healthcare

In healthcare, fusers are essential for producing high-resolution medical images, patient records, and diagnostic reports. The reliability and durability of fusers are crucial in ensuring accurate and timely diagnosis and treatment.

Education

Educational institutions rely on printers for handouts, assignments, and presentations. Fusers with high-volume printing capabilities and durability can handle the demands of student printing while maintaining consistent quality.

Manufacturing

In manufacturing, fusers are used for printing technical drawings, production schedules, and quality control documents. The ability to withstand high temperatures and heavy workloads is critical for fusers in this industry.

Retail

Retail businesses use printers for receipts, invoices, and marketing materials. Fusers with energy-efficient features and fast warm-up times are ideal for high-volume printing in retail environments.

Challenges and Solutions

Specific challenges and solutions related to fuser performance include:

- High-volume printing requirements:Fusers with high-capacity and robust designs can handle large print volumes without compromising quality or reliability.

- Durability and longevity concerns:Durable fusers with long lifespans reduce maintenance costs and ensure consistent printing performance over time.

- Environmental regulations and energy efficiency:Energy-efficient fusers comply with environmental regulations and reduce operating costs.

Case Studies

Case studies demonstrate the benefits of fuser technology in real-world scenarios:

- A healthcare provider implemented fusers with high-resolution printing capabilities, resulting in improved diagnostic accuracy and reduced patient wait times.

- An educational institution upgraded to fusers with high-volume printing capacity, leading to reduced printing costs and improved productivity.

- A manufacturing plant replaced its old fusers with energy-efficient models, resulting in significant cost savings and reduced environmental impact.

“The performance of printer fusers is crucial for ensuring efficient and reliable printing operations. Selecting the right fuser technology can improve productivity, reduce costs, and enhance the overall printing experience.”- Industry Expert

Technical Specifications

Printer fusers have various technical specifications that determine their performance and capabilities. These specifications include temperature range, pressure, and power consumption, among others.

Temperature Range

The temperature range of a fuser refers to the range of temperatures at which it can operate. Different types of fusers have different temperature ranges, depending on the materials used and the desired output quality.

- Laser fusers:Typically operate in the range of 150-250 degrees Celsius (300-480 degrees Fahrenheit).

- LED fusers:Operate at lower temperatures compared to laser fusers, typically around 100-180 degrees Celsius (210-360 degrees Fahrenheit).

- Inkjet fusers:Operate at even lower temperatures, typically around 50-120 degrees Celsius (120-250 degrees Fahrenheit).

Pressure

The pressure applied by the fuser is another important specification. Pressure helps to fuse the toner particles to the paper and create a permanent bond. Different types of fusers use different pressure levels.

- Laser fusers:Typically apply pressure in the range of 1-5 kilograms per square centimeter (14-70 pounds per square inch).

- LED fusers:Apply lower pressure compared to laser fusers, typically around 0.5-2 kilograms per square centimeter (7-28 pounds per square inch).

- Inkjet fusers:Apply the least amount of pressure, typically around 0.1-0.5 kilograms per square centimeter (1-7 pounds per square inch).

Power Consumption

The power consumption of a fuser refers to the amount of electrical power it consumes during operation. Power consumption can vary depending on the size and type of fuser.

- Laser fusers:Typically consume the most power, ranging from 100 to 500 watts.

- LED fusers:Consume less power compared to laser fusers, typically ranging from 50 to 200 watts.

- Inkjet fusers:Consume the least amount of power, typically ranging from 10 to 50 watts.

Troubleshooting Guide

Printer fusers can encounter various issues that affect their performance and output quality. To assist users in diagnosing and resolving common fuser problems, the following troubleshooting guide provides step-by-step instructions and potential solutions.

Before attempting any troubleshooting steps, ensure that the printer is properly connected, powered on, and has sufficient paper and toner. Additionally, check the fuser unit for any visible damage or debris that may be causing the issue.

Fuser Not Heating Up

- Check power supply:Ensure that the printer is receiving power and that the fuser unit is properly connected to the power source.

- Inspect fuser film:The fuser film may be damaged or worn, preventing proper heating. Inspect the film for any tears, wrinkles, or other damage and replace it if necessary.

- Clean fuser contacts:Dirty or corroded fuser contacts can prevent proper electrical connection. Clean the contacts with a cotton swab dipped in isopropyl alcohol.

Fuser Overheating

- Check ventilation:Ensure that the printer is in a well-ventilated area with adequate airflow to prevent overheating.

- Inspect fuser fan:The fuser fan helps dissipate heat from the unit. Check if the fan is running properly and clean any dust or debris that may be obstructing its operation.

- Replace fuser assembly:If the overheating issue persists, it may be necessary to replace the entire fuser assembly.

Paper Jams or Wrinkles

- Check paper type:Ensure that the paper being used is compatible with the printer and fuser unit. Some paper types may be too thick or thin for the fuser to handle properly.

- Adjust fuser pressure:The fuser pressure may need to be adjusted to ensure proper contact with the paper. Consult the printer’s user manual for instructions on adjusting the pressure.

- Clean fuser rollers:Paper dust and debris can accumulate on the fuser rollers, causing paper jams or wrinkles. Clean the rollers with a soft, lint-free cloth.

Future Trends: What Is A Printer Fuser

The printer fuser technology is continuously evolving, with ongoing research and development efforts aimed at improving performance, efficiency, and sustainability.

One emerging trend is the development of fusers that operate at lower temperatures. This can reduce energy consumption and extend the life of fuser components. Another trend is the use of new materials and coatings that improve durability and reduce wear and tear.

Advancements in Fuser Design

Researchers are exploring innovative fuser designs to enhance print quality and productivity. One such advancement is the use of multiple fuser rollers, which can provide more even heating and reduce the risk of paper jams.

Additionally, there is a growing interest in the development of self-cleaning fusers. These fusers would eliminate the need for manual cleaning, reducing maintenance costs and downtime.

Sustainability and Environmental Impact

The environmental impact of printer fusers is also a key area of focus. Manufacturers are developing fusers that use less energy and produce fewer emissions.

One promising approach is the use of induction heating, which can significantly reduce energy consumption compared to traditional fuser technologies.

Glossary of Terms

This comprehensive glossary provides clear definitions and explanations of technical terms related to printer fusers, helping users understand the concepts and terminology used in the industry. The glossary is organized into categories for easy reference, including “Fuser Components”, “Fuser Processes”, and “Fuser Troubleshooting”.

Examples and illustrations enhance understanding, and a search function allows users to quickly find specific terms.

Fuser Components

- Fuser Film:A thin, heat-resistant material that transfers toner to paper.

- Fuser Roller:A heated roller that applies pressure and heat to fuse toner to paper.

- Pressure Roller:A roller that applies pressure to the paper as it passes through the fuser.

- Thermistor:A temperature sensor that monitors the temperature of the fuser roller.

- Fuser Lamp:A heat source that generates heat for the fuser roller.

Fuser Processes

- Fusing:The process of bonding toner to paper using heat and pressure.

- Fixation:The final stage of the printing process where toner is permanently attached to paper.

- Glazing:A process that gives the printed image a glossy finish.

- Scoring:A process that creates creases in the paper to facilitate folding.

Fuser Troubleshooting, What is a printer fuser

- Wrinkled Paper:Can be caused by incorrect fuser temperature or pressure.

- Toner Smearing:Can be caused by worn or damaged fuser components.

- Fuser Jam:Can be caused by foreign objects or paper debris.

- Fuser Overheating:Can be caused by a faulty thermistor or fuser lamp.

Q&A

What is the role of a printer fuser?

The fuser is responsible for fusing toner particles to paper, making the print permanent.

What are the different types of printer fusers?

There are several types of fusers, including heat roller fusers, film fusers, pressure roller fusers, and nipper roller fusers.

How can I maintain my printer fuser?

Regular cleaning and lubrication can help extend the lifespan of your fuser.

What are some common fuser issues?

Common fuser issues include paper jams, toner smudging, and ghosting.

How can I troubleshoot fuser issues?

Troubleshooting fuser issues involves identifying the problem and implementing appropriate solutions.