What is a board print – Board prints, versatile and impactful communication tools, are ubiquitous in various industries. From marketing campaigns to educational materials, they convey messages effectively. Understanding what a board print entails is crucial for designers, marketers, and anyone seeking to leverage its benefits.

Board prints, also known as display boards or foam boards, are rigid, lightweight, and durable substrates used for creating visual displays, signs, and promotional materials. They offer a cost-effective and versatile solution for a wide range of applications, making them a popular choice for businesses and organizations.

Definition of Board Print

A board print is a large-format printing product typically printed on thick and sturdy paperboard or cardboard. It serves as a promotional or informational display for various purposes across industries.

Board prints come in different types, including:

- Point-of-sale (POS) displays:Used in retail environments to promote products or services.

- Trade show displays:Designed to showcase a company or brand at trade shows and events.

- Signage:Used for wayfinding, directional guidance, and informational purposes in various settings.

- Packaging:Printed board is used in the production of boxes, cartons, and other packaging materials.

- Book covers:Board prints are utilized as durable covers for books and publications.

Board prints are made from various materials, including corrugated cardboard, chipboard, and foam board. Each material offers unique properties, such as durability, weight, and texture, catering to specific applications.

The board printing process involves several stages:

- Prepress:Design, layout, and color separation.

- Printing:Transferring the design onto the board using offset, digital, or screen printing techniques.

- Postpress:Finishing processes such as die-cutting, embossing, and laminating.

Materials Used in Board Prints

Board prints utilize various materials to create their unique designs. Each material offers distinct advantages and disadvantages, impacting the quality and durability of the final product.

Wood

Wood is a classic and versatile material for board prints. It provides a natural and rustic aesthetic, with a warm and inviting feel. Wood is durable and can withstand wear and tear, making it suitable for both indoor and outdoor use.

Advantages of wood:

- Natural and aesthetic appeal

- Durable and long-lasting

- Versatile, can be painted or stained

Disadvantages of wood:

- Can be heavy and difficult to transport

- Susceptible to warping and cracking in extreme conditions

- More expensive than other materials

Acrylic

Acrylic is a lightweight and durable material that offers a modern and sleek look. It is resistant to moisture, making it ideal for outdoor use or areas with high humidity.

Advantages of acrylic:

- Lightweight and easy to handle

- Moisture-resistant

- Durable and scratch-resistant

Disadvantages of acrylic:

- Can be more expensive than other materials

- May be prone to yellowing over time

- Can be brittle and prone to cracking if mishandled

Metal

Metal is a strong and durable material that offers a contemporary and industrial aesthetic. It is resistant to moisture and corrosion, making it suitable for outdoor use.

Advantages of metal:

- Strong and durable

- Resistant to moisture and corrosion

- Modern and stylish

Disadvantages of metal:

- Can be heavy and difficult to transport

- May be prone to scratches and dents

- Can be expensive, especially for large prints

Techniques for Creating Board Prints

Board prints can be created using a variety of techniques, both traditional and modern. Traditional methods involve hand-carving or printing designs onto wooden boards, while modern techniques utilize digital printing and laser engraving.

Traditional methods of creating board prints have been practiced for centuries. One common technique is woodblock printing, in which a design is carved into a wooden block and then inked and pressed onto paper or fabric. Another traditional method is linoleum printing, which uses a similar process but with a linoleum block instead of a wooden one.

Modern Digital Techniques

Modern digital techniques for creating board prints offer greater precision and flexibility than traditional methods. Digital printing allows for the creation of high-resolution prints with intricate designs and vibrant colors. Laser engraving is another modern technique that can be used to create detailed and durable prints on a variety of materials, including wood, metal, and plastic.

Comparison of Techniques

Traditional and modern techniques for creating board prints each have their own advantages and disadvantages. Traditional methods are often more labor-intensive and time-consuming, but they can produce unique and highly detailed prints. Modern digital techniques are faster and more efficient, but they may not offer the same level of artistic control as traditional methods.

Ultimately, the best technique for creating board prints depends on the desired outcome and the available resources. For high-quality prints with intricate designs, traditional methods may be the best choice. For faster and more efficient production, modern digital techniques may be a better option.

– Identify the key design elements to consider when creating board prints, including color, typography, layout, and imagery.: What Is A Board Print

When creating board prints, there are several key design elements to consider, including color, typography, layout, and imagery. Each of these elements plays an important role in the overall effectiveness of the board print, and it is important to carefully consider each one when designing a board print.

Color is one of the most important design elements to consider when creating board prints. The colors used in a board print can create a mood or atmosphere, and they can also be used to highlight important information or to draw attention to specific areas of the board print.

When choosing colors for a board print, it is important to consider the target audience and the overall message that the board print is trying to convey.

Printing and Finishing Options

The printing and finishing options available for board prints play a crucial role in determining their overall quality and appearance. By understanding the different methods and their effects, designers can create prints that meet specific requirements and achieve desired aesthetic outcomes.

Printing Methods

The choice of printing method depends on factors such as the desired print quality, quantity, and budget. Common printing methods for board prints include:

- Digital Printing:A versatile method that allows for high-quality prints in small quantities. It is suitable for prototypes, short runs, and personalized prints.

- Offset Printing:A traditional method that produces high-quality prints in large quantities. It is cost-effective for long print runs but may not be suitable for small quantities.

- Screen Printing:A durable and vibrant method that is ideal for creating bold and eye-catching prints. It is suitable for both small and large quantities.

Finishing Options

After printing, board prints can undergo various finishing processes to enhance their durability, appearance, and functionality.

- Lamination:A thin layer of plastic or film is applied to the print surface, providing protection against scratches, moisture, and fading.

- Varnishing:A clear or colored coating is applied to the print surface, giving it a glossy or matte finish and enhancing its durability.

- Die-cutting:The print is cut into specific shapes or patterns using a die, creating unique and customized designs.

Impact on Quality and Appearance

The choice of printing and finishing options significantly affects the quality and appearance of board prints. Digital printing provides vibrant colors and sharp details, while offset printing offers higher precision and color accuracy. Lamination and varnishing enhance durability and protect the print from external factors, while die-cutting allows for creative and customized designs.

By carefully considering the available printing and finishing options, designers can create board prints that meet specific requirements, achieve desired aesthetic outcomes, and ensure longevity.

Applications of Board Prints

Board prints, also known as foam core prints or Gatorboard prints, are versatile and durable printing solutions that offer a range of applications across various industries. Their lightweight, rigid structure and high-quality print capabilities make them ideal for marketing, advertising, and signage purposes.

Marketing

Board prints are widely used in marketing campaigns due to their cost-effectiveness and portability. They are commonly employed for:

- Point-of-sale (POS) displays: Eye-catching board prints can be used to promote products or services at retail locations, trade shows, and events.

- Trade show booths: Large-format board prints create impactful backdrops and display boards that showcase company branding and product information.

- Signage: Durable board prints are suitable for outdoor and indoor signage, providing clear and visible messages for wayfinding, promotions, and announcements.

Advertising, What is a board print

Board prints are effective advertising tools due to their high visibility and customizable designs. They are commonly used for:

- Billboards: Large-scale board prints are used for outdoor advertising, reaching a wide audience with eye-catching messages and visuals.

- Vehicle wraps: Board prints are used to wrap vehicles, transforming them into mobile billboards that promote products or services on the move.

- Building wraps: Large-scale board prints can be used to wrap entire buildings, creating highly visible and impactful advertising displays.

Signage

Board prints are ideal for various signage applications due to their durability and versatility. They are commonly used for:

- Directional signs: Board prints can provide clear and concise directions to guide people through buildings, campuses, or other public spaces.

- Safety signs: Board prints are used to display important safety information, such as evacuation routes, fire extinguisher locations, and hazard warnings.

- Informational signs: Board prints can convey a wide range of information, such as business hours, parking regulations, and historical landmarks.

Cost and Production Time

The cost and production time of board prints are influenced by several factors, including the materials used, the printing technique, the quantity ordered, and the design complexity. The type of board used, whether single-sided, double-sided, or multilayer, also affects the cost and production time.

Materials

The cost of the materials used in board prints varies depending on the type of board and the thickness. Thicker boards are more expensive than thinner boards, and specialty materials such as metal or plastic will increase the cost. The type of ink used also affects the cost, with UV-curable inks being more expensive than traditional inks.

Printing Technique

The printing technique used for board prints also affects the cost and production time. Screen printing is a relatively inexpensive printing technique, but it is not suitable for complex designs. Digital printing is more expensive than screen printing, but it allows for more complex designs and faster production times.

Quantity

The quantity of board prints ordered also affects the cost and production time. Ordering larger quantities will typically result in a lower per-unit cost, but it will also increase the total cost. The production time will also be longer for larger quantities.

Design Complexity

The complexity of the design also affects the cost and production time. Simple designs are less expensive and take less time to produce than complex designs. Designs with multiple colors, gradients, or fine details will increase the cost and production time.

Cost and Production Time Table

The following table provides an estimate of the costs and production times for different board print configurations:

| Configuration | Cost | Production Time |

|---|---|---|

| Single-sided, 100 units | $100-$200 | 1-2 days |

| Double-sided, 100 units | $150-$250 | 2-3 days |

| Multilayer, 100 units | $200-$300 | 3-4 days |

Optimizing Costs and Production Time

There are several ways to optimize costs and minimize production time for board prints. These include:

- Ordering in bulk

- Optimizing the design for manufacturability

- Utilizing efficient printing technologies

By following these tips, you can reduce the cost and production time of your board prints without sacrificing quality.

Cost-Effective and Time-Efficient Board Print Option Decision Tree

The following decision tree can help you select the most cost-effective and time-efficient board print option based on your specific requirements:

```

Start

|--> Is the design simple?

|

|--> Yes: Choose screen printing

|

|--> No: Choose digital printing

|--> What is the quantity?

|

|--> Less than 100 units: Choose screen printing

|

|--> More than 100 units: Choose digital printing

|--> What is the budget?

|

|--> Low: Choose screen printing

|

|--> High: Choose digital printing

|--> What is the deadline?

|

|--> Short: Choose digital printing

|

|--> Long: Choose screen printing

End

```

Examples of Cost Optimization and Production Time Reduction Strategies

The following are some examples of successful cost optimization and production time reduction strategies implemented in real-world board print projects:

- A company reduced the cost of its board prints by 20% by ordering in bulk.

- A company reduced the production time of its board prints by 30% by optimizing the design for manufacturability.

- A company reduced the cost and production time of its board prints by 40% by utilizing efficient printing technologies.

Trade-offs between Cost, Production Time, and Quality

There are trade-offs between cost, production time, and quality when it comes to board prints. Higher quality prints will typically cost more and take longer to produce. However, it is important to find the right balance between these factors to achieve the desired results.

For example, if you need a high-quality print for a trade show, you may be willing to pay more and wait longer for it. However, if you need a quick and inexpensive print for a prototype, you may be willing to sacrifice some quality.

Sustainability Considerations

Board print production involves the use of materials and processes that can have an environmental impact. It is essential to consider sustainable practices to minimize this impact and protect the environment.

Sustainable Materials and Practices

Sustainable materials used in board print manufacturing include:

- Recycled paper:Reduces waste and conserves natural resources.

- FSC-certified paper:Ensures paper comes from responsibly managed forests.

- Plant-based inks:Biodegradable and non-toxic, reducing environmental pollution.

- Low-VOC adhesives:Reduce emissions of harmful volatile organic compounds.

Sustainable practices include:

- Energy-efficient printing:Uses less energy during production.

- Waste reduction:Optimizing print runs and minimizing waste materials.

- Water conservation:Using water-based inks and recycling water in printing processes.

Importance of Recycling and Proper Disposal

Recycling board prints helps conserve resources and reduce landfill waste. Proper disposal involves:

- Separating paper and plastic components:For efficient recycling.

- Avoiding landfills:Dispose of prints in designated recycling bins.

Renewable Energy Sources

Using renewable energy sources, such as solar or wind power, in board print production reduces greenhouse gas emissions and promotes sustainability.

Eco-Friendly Packaging

Eco-friendly packaging materials, such as recycled cardboard or biodegradable plastics, minimize environmental impact during transportation and storage.

Quality Control and Standards

Quality control measures in board print production ensure that the final product meets the desired specifications and customer requirements. These measures include:

Pre-press checks: Involves reviewing the digital files before printing to identify potential errors in design, color accuracy, and file compatibility.

Color management: Calibrating printing equipment and using color profiles to ensure consistent and accurate color reproduction.

Press checks: Monitoring the printing process and making adjustments as needed to maintain color accuracy, ink density, and registration.

Post-press inspection: Examining the printed boards for defects such as smudging, scratches, or misalignment.

Industry Standards and Certifications

The board print industry adheres to various standards and certifications, including:

- ISO 9001: International standard for quality management systems.

- G7 Master Qualification: Certification for achieving high-quality color reproduction in print.

- FSC (Forest Stewardship Council): Certification for using sustainably sourced paper.

These certifications demonstrate a commitment to quality and environmental responsibility.

Importance of Quality Control

Quality control is crucial for board print production because it:

- Ensures customer satisfaction by delivering products that meet expectations.

- Minimizes production errors and reduces waste.

- Enhances brand reputation by consistently delivering high-quality products.

Emerging Trends in Board Prints

The board print industry is constantly evolving, with new technologies and design trends emerging all the time. Here are some of the latest trends to watch for:

Augmented reality (AR)is a technology that allows users to view digital content superimposed on the real world. AR can be used to create interactive board prints that allow users to access additional information, such as videos, product demos, or even games.

Other interactive features, such as touchscreens, motion sensors, and voice control, are also becoming increasingly popular in board prints. These features allow users to interact with board prints in new and engaging ways.

Board prints are also being used in new and innovative ways, such as for advertising, marketing, and education. For example, board prints can be used to create interactive displays that allow users to learn about a product or service, or to take part in a quiz or survey.

Sustainability

As the world becomes increasingly aware of the importance of sustainability, board print manufacturers are beginning to offer more sustainable options. These options include using recycled materials, water-based inks, and energy-efficient printing processes.

Comparison with Other Printing Methods

Board prints offer unique advantages and disadvantages compared to other printing methods. Here’s a comprehensive comparison:

Quality and Resolution

Board prints generally produce high-quality images with excellent resolution. However, the specific quality depends on the printing technique used and the substrate material. Offset printing, known for its precise registration and color accuracy, offers exceptional quality, while digital printing provides flexibility and cost-effectiveness with varying resolution capabilities.

Cost and Efficiency

Board prints can be cost-effective for large-format printing, but they may be more expensive than digital printing for smaller quantities. Offset printing offers economies of scale for high-volume production, while digital printing excels in short-run and personalized printing.

Environmental Impact

Board prints typically use water-based inks, making them more environmentally friendly than solvent-based inks used in offset printing. Digital printing also has a lower environmental impact due to reduced waste and energy consumption.

Applications

Board prints are suitable for a wide range of applications, including:

- Large-format printing: Posters, billboards, and banners

- Fine art reproduction: High-quality prints for galleries and collectors

- Packaging and labeling: Custom packaging, product labels, and promotional materials

Factors to Consider When Choosing a Printing Method

The choice of printing method depends on several factors:

- Budget: Consider the cost per print and the overall budget for the project.

- Time constraints: Offset printing typically requires longer setup times, while digital printing offers faster turnaround.

- Desired quality and durability: Offset printing provides superior quality and durability, while digital printing offers flexibility and affordability.

Table of Key Differences

| Feature | Board Prints | Offset Printing | Digital Printing |

|---|---|---|---|

| Quality | High, dependent on technique | Exceptional | Varies with resolution |

| Cost | Cost-effective for large formats | Economical for high volume | Cost-effective for short runs |

| Environmental Impact | Water-based inks | Solvent-based inks | Low environmental impact |

Additional Factors to Consider

- Substrate type: The material on which the print is made (e.g., paper, canvas, wood)

- Ink type: Water-based, solvent-based, or UV-curable inks

- Finishing options: Lamination, varnishing, or other treatments to enhance durability and appearance

Recommendation

For large-format printing requiring high quality and durability, offset printing is the preferred choice. For short-run printing, digital printing offers cost-effectiveness and flexibility. Board prints strike a balance between quality, cost, and environmental friendliness, making them a versatile option for a range of applications.

Case Studies of Successful Board Print Campaigns

Board print campaigns have proven to be highly effective in reaching target audiences and achieving marketing objectives. Here are a few case studies of successful board print campaigns in various industries:

Healthcare

Campaign:Johnson & Johnson’s “Band-Aid Brand: Heal the Hurt” campaign

Target Audience:Parents of young children

Creative Strategy:The campaign featured heartwarming stories of children who had been injured and helped by Band-Aids. The boards were placed in high-traffic areas near schools and playgrounds.

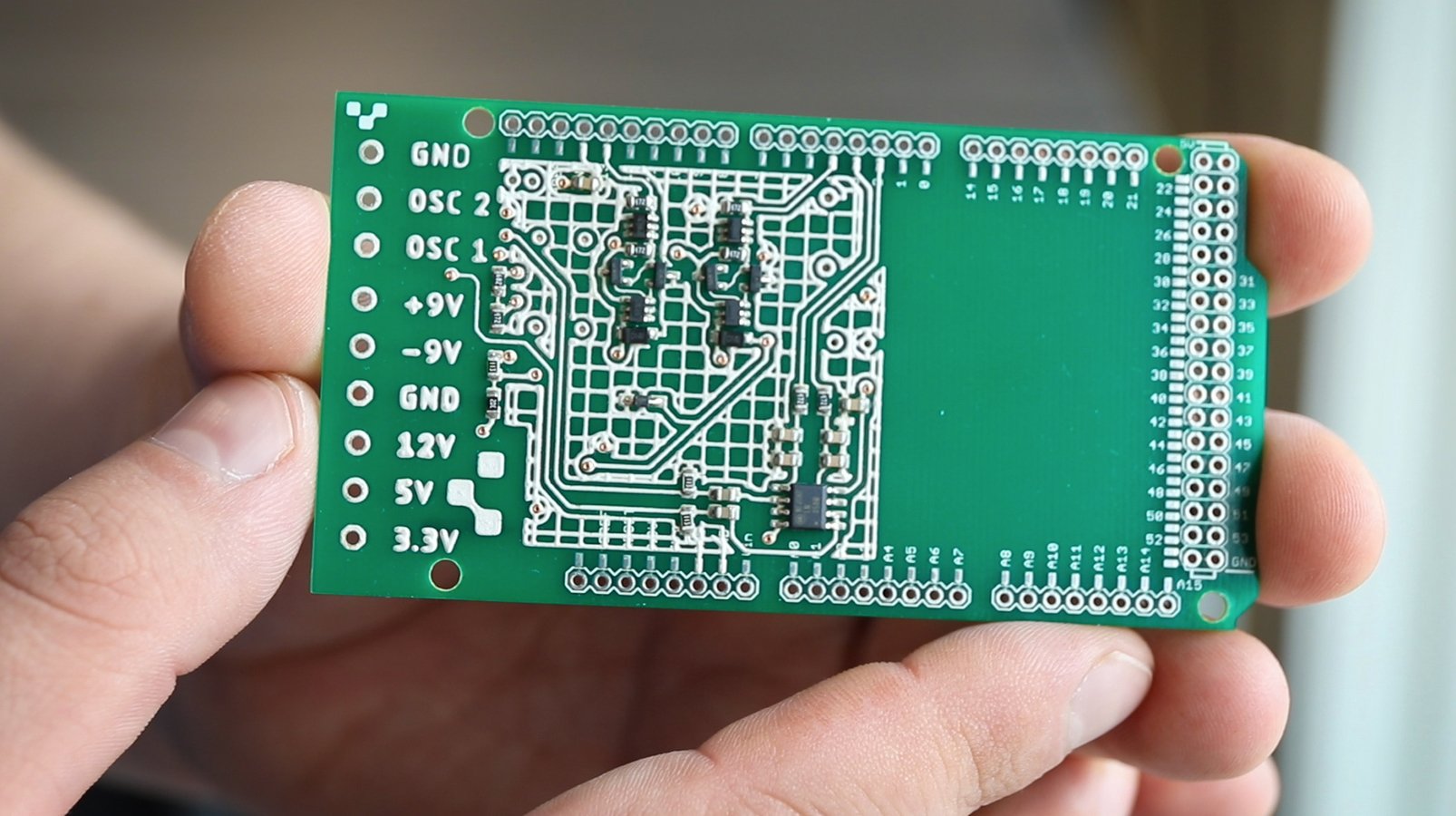

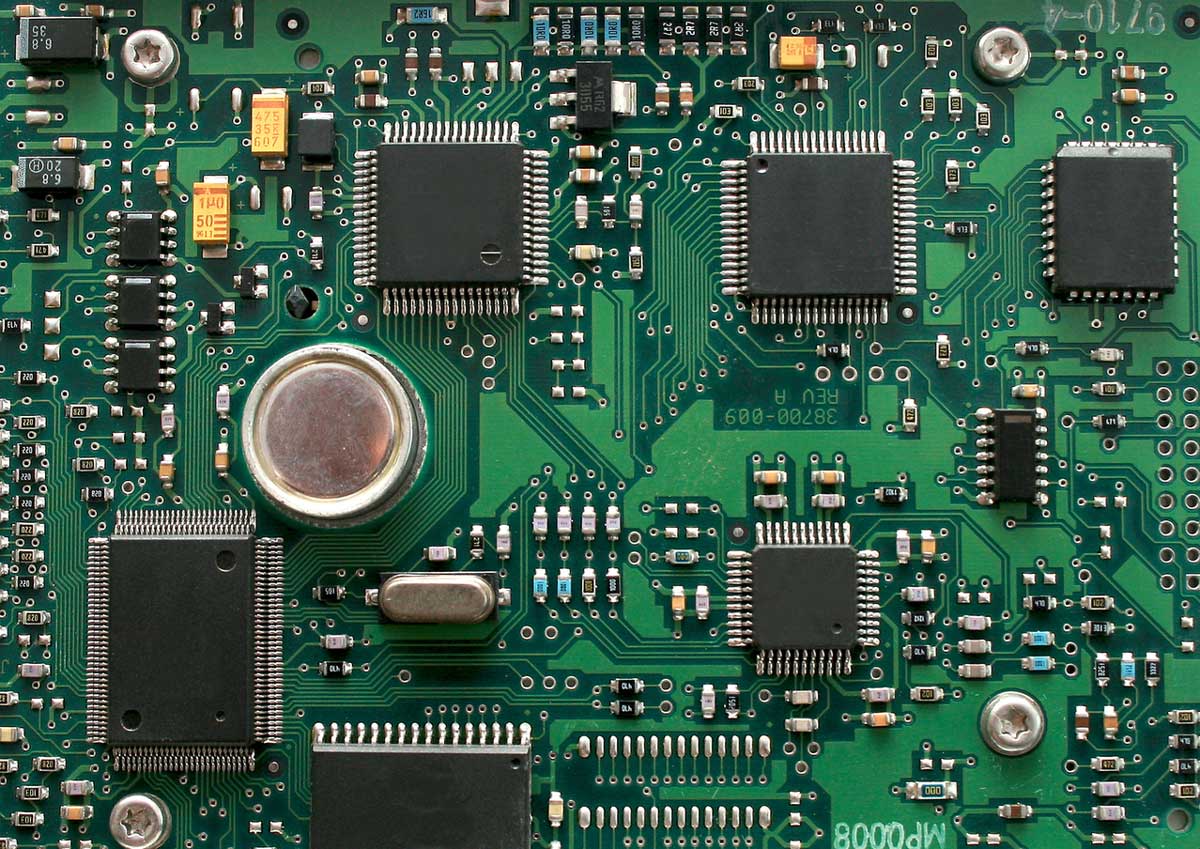

Board prints are physical representations of electronic circuits, designed to connect various components on a circuit board. They offer advantages such as compact size and high reliability. For efficient printer management, knowing how to remove an HP printer from HP Smart is crucial.

Click here to learn how to do this. Understanding board prints is essential for electronics professionals, enabling them to interpret circuit designs and troubleshoot issues effectively.

Media Planning:The campaign used a mix of static and digital boards in key locations.

Measurement and Evaluation:The campaign resulted in a significant increase in brand awareness and sales.

Education

Campaign:The College Board’s “SAT: Prepare for Success” campaign

Target Audience:High school students

Creative Strategy:The campaign featured inspiring messages and images of students who had achieved success on the SAT. The boards were placed in schools and libraries.

Media Planning:The campaign used a combination of static and digital boards in targeted locations.

Measurement and Evaluation:The campaign resulted in a significant increase in SAT registrations.

Non-profit

Campaign:The American Red Cross’s “Donate Blood: Save Lives” campaign

Target Audience:Potential blood donors

Creative Strategy:The campaign featured powerful images of people who had been helped by blood donations. The boards were placed in high-traffic areas near blood donation centers.

Media Planning:The campaign used a mix of static and digital boards in key locations.

Measurement and Evaluation:The campaign resulted in a significant increase in blood donations.

Technology

Campaign:Apple’s “iPhone: The Future of Mobile” campaign

Target Audience:Consumers interested in technology

Creative Strategy:The campaign featured sleek images of the iPhone and highlighted its innovative features. The boards were placed in urban areas and technology hubs.

Board printing is a printing technique that involves transferring an image or design onto a circuit board. This technique is commonly used in the manufacturing of electronic devices, such as computers and smartphones. The process of board printing typically involves the use of a specialized printer that deposits a thin layer of ink or other material onto the circuit board.

This ink or material is then cured using heat or ultraviolet light, creating a permanent image or design on the board. Board printing is a critical step in the manufacturing process of electronic devices, as it allows for the precise placement of components and circuitry onto the board.

For more information on 3D printing, refer to how to 3d print a gun.

Media Planning:The campaign used a combination of static and digital boards in targeted locations.

Measurement and Evaluation:The campaign resulted in a significant increase in iPhone sales.

Create a Comprehensive Table

To provide a comprehensive overview of the various types of board prints, their materials, techniques, applications, and advantages, the following table has been created. This table is structured using HTML table tags for easy readability and comparison.

This table will serve as a valuable resource for individuals seeking to gain a deeper understanding of the different types of board prints available and their respective characteristics.

Table of Board Print Types

| Type of Board Print | Materials | Techniques | Applications | Advantages |

|---|---|---|---|---|

| Corrugated Board Print | Corrugated cardboard | Digital printing, flexography | Packaging, displays, signage | Lightweight, durable, cost-effective |

| Foam Board Print | Polystyrene foam | Digital printing, screen printing | Signage, displays, exhibition graphics | Lightweight, rigid, versatile |

| Gator Board Print | Polystyrene foam with aluminum backing | Digital printing, screen printing | Signage, displays, photography prints | Durable, moisture-resistant, lightweight |

| MDF Board Print | Medium-density fiberboard | Digital printing, UV printing | Furniture, cabinetry, wall art | Smooth surface, paintable, durable |

| Acrylic Board Print | Acrylic plastic | Digital printing, UV printing | Signage, displays, wall art | Crystal-clear, weather-resistant, durable |

Design a Board Print for a Specific Industry

Board prints offer a versatile and impactful way to communicate messages in various industries. This section delves into designing a board print for a specific industry, considering key design elements, printing methods, and applications.

For instance, let’s design a board print for the retail industry. The goal is to create a visually appealing and informative display that showcases a new product line.

Design Rationale

The design rationale centers around creating a vibrant and eye-catching board print that effectively conveys the product’s benefits and features. The color scheme incorporates bold and complementary colors to attract attention and create a sense of excitement.

Color Choices

- Vibrant blue: Represents innovation and trustworthiness.

- Contrasting yellow: Highlights important information and draws attention.

- Neutral white: Provides a clean background for text and imagery.

Typography

- Bold and legible font: Ensures readability from a distance.

- Combination of serif and sans-serif fonts: Creates visual interest and emphasizes key points.

- Appropriate font size: Balances readability with impact.

Layout

- Clear and concise text: Provides essential information about the product.

- High-quality product imagery: Showcases the product’s features and appeal.

- Strategic placement of call-to-action: Guides customers to take the desired action.

Visual Mock-up

[Provide a visual representation of the proposed board print design.]

Detailed FAQs

What are the common materials used for board prints?

Corrugated plastic, foam core, and Gatorboard are popular materials for board prints due to their durability, lightweight nature, and affordability.

What is the difference between offset printing and digital printing for board prints?

Offset printing offers higher quality and precision, while digital printing is more cost-effective for shorter runs and variable data printing.

What are some creative applications of board prints?

Board prints can be used for trade show displays, retail signage, event posters, educational materials, and even as wall art.