In the realm of document management, collating plays a pivotal role in organizing and assembling printed materials. What does print collate mean? It refers to the process of gathering, arranging, and combining multiple pages or sheets of paper in a specific order to form a complete document.

From offices to print shops, collating finds widespread applications, ensuring that documents are presented in a cohesive and professional manner.

This guide delves into the intricacies of collating, exploring its various methods, best practices, and troubleshooting techniques. Whether you’re a novice or an experienced professional, this comprehensive resource will empower you with the knowledge and skills to master the art of collating.

Collating Basics: What Does Print Collate Mean

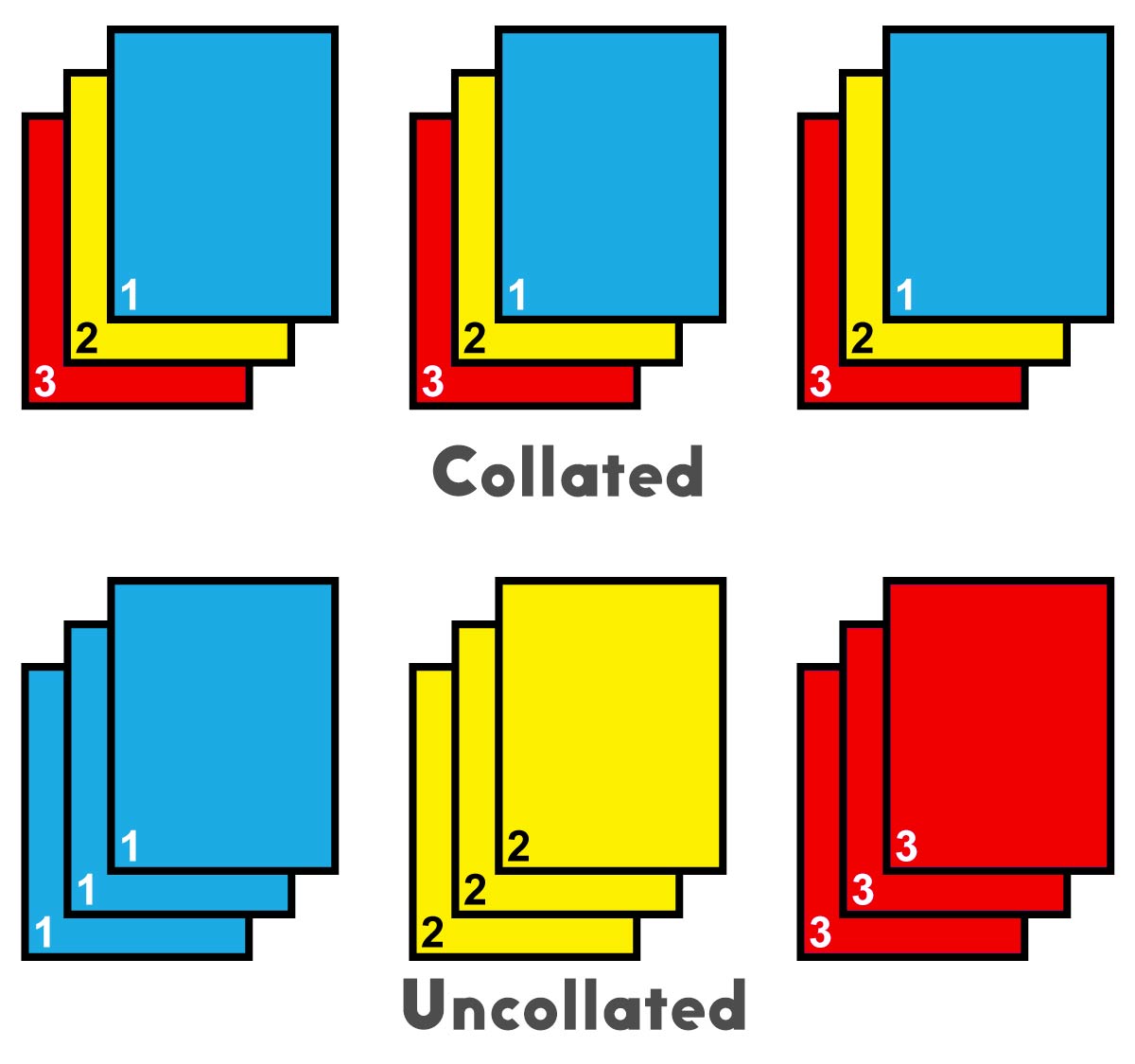

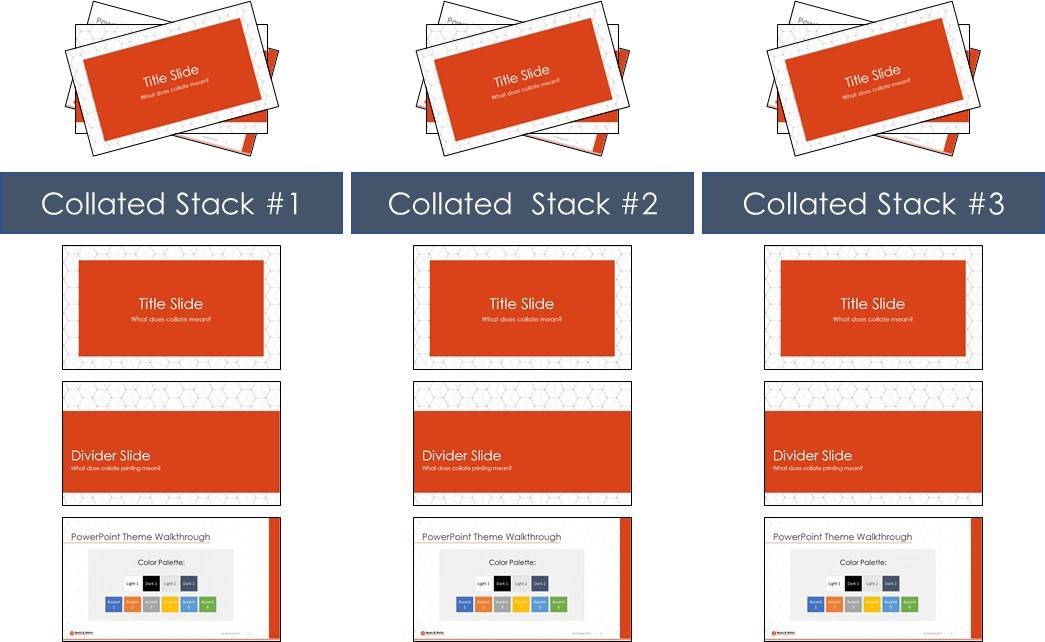

Collating is the process of gathering and arranging printed documents in a specific order. It involves combining multiple sheets of paper into a complete set, ensuring that the pages are in the correct sequence. Collating is commonly used in various industries, including office environments, print shops, and mail rooms.

Types of Collating Methods

There are two primary methods of collating: manual collating and machine collating.

- Manual collatingis performed by hand, where an individual gathers and arranges the documents in the desired order. This method is typically used for small batches of documents or when accuracy is crucial.

- Machine collatingutilizes specialized equipment to automate the collating process. Machine collators are designed to handle larger volumes of documents efficiently and accurately.

Applications of Collating

Collating finds applications in a wide range of industries:

- Office environments: Collating is essential for organizing documents such as reports, presentations, and proposals.

- Print shops: Collating is a crucial step in the production of printed materials like brochures, booklets, and manuals.

- Mail rooms: Collating is used to assemble and prepare mailings, ensuring that each recipient receives the correct set of documents.

Collating Equipment

Collating machines are essential equipment for businesses and organizations that need to produce large volumes of collated documents. There are various types of collating machines available, each with its own features and capabilities. Choosing the right collating machine for your specific needs is important to ensure efficient and accurate document production.

The following are the different types of collating machines available:

- Manual Collating Machines:These machines require manual operation to collate documents. They are typically used for small-volume collating tasks and are affordable.

- Semi-Automatic Collating Machines:These machines combine manual and automated features. They can collate larger volumes of documents than manual collating machines and are more efficient.

- Automatic Collating Machines:These machines are fully automated and can collate large volumes of documents quickly and accurately. They are typically used for high-volume collating tasks and are more expensive than manual and semi-automatic collating machines.

When choosing a collating machine, consider the following factors:

- Volume of Documents:Determine the number of documents you need to collate on a regular basis. This will help you choose a machine with the appropriate capacity.

- Speed:Consider the speed at which you need to collate documents. If you need to collate large volumes of documents quickly, choose a machine with a high speed.

- Accuracy:Ensure that the collating machine you choose is accurate and can produce collated documents without errors.

- Features:Consider the features that are important to you, such as the ability to staple or fold documents.

- Budget:Determine your budget for a collating machine. The price of collating machines varies depending on their features and capabilities.

The following table compares the different types of collating machines, including their features, capabilities, and price ranges:

| Type of Collating Machine | Features | Capabilities | Price Range |

|---|---|---|---|

| Manual Collating Machines | Manual operation, affordable | Small-volume collating tasks | $50-$200 |

| Semi-Automatic Collating Machines | Manual and automated features, efficient | Larger volumes of documents than manual collating machines | $200-$500 |

| Automatic Collating Machines | Fully automated, quick and accurate | High-volume collating tasks | $500-$2,000 |

Once you have chosen a collating machine, follow the manufacturer’s instructions for use. Here is a general guide on how to use a collating machine:

- Load the documents into the machine’s input tray.

- Set the collating order and any other desired settings.

- Start the collating process.

- Remove the collated documents from the output tray.

If you encounter any problems when using a collating machine, refer to the troubleshooting section in the machine’s user manual. Common problems that may occur include:

- Paper jams:Ensure that the paper is loaded correctly and that there are no obstructions in the machine.

- Misfeeds:Check that the documents are aligned correctly and that the machine is set to the correct paper size.

- Incomplete collating:Ensure that all of the documents were loaded into the machine and that the machine is set to the correct collating order.

Collating Processes

Collating is a multi-step process that involves gathering, organizing, and assembling printed materials in a specific order. The accuracy and efficiency of the collating process are crucial to ensure the integrity of the final product.

Techniques for Ensuring Accuracy and Efficiency

Various techniques are employed to enhance the accuracy and efficiency of collating processes, including:

- Manual Collating:Involves manually gathering and assembling printed materials by hand. It is suitable for small quantities and requires careful attention to detail.

- Automated Collating:Utilizes machines or software to automate the collating process, reducing the risk of human error and increasing speed and efficiency.

The choice between manual and automated collating depends on factors such as the volume of materials, the desired accuracy level, and the available resources.

Tips for Optimizing Collating Workflows

To optimize collating workflows, consider the following tips:

| Step | Description |

|---|---|

| Preparation: | Gather all necessary materials, organize them in the correct order, and ensure they are complete. |

| Collating: | Use appropriate techniques to assemble the materials in the desired order. |

| Verification: | Carefully check the collated materials for accuracy and completeness. |

| Packaging: | Package the collated materials securely for storage or distribution. |

- Organization:Clearly label and organize materials to facilitate efficient collating.

- Verification:Implement quality control measures to ensure accuracy.

- Troubleshooting:Identify and resolve common collating issues, such as missing or duplicate pages.

Collating Settings

Collating machines offer various settings that can be adjusted to optimize the collating process for different types of documents. These settings typically include:

Number of copies

This setting specifies the number of copies to be collated for each set.

Collating sequence

This setting determines the order in which the pages are collated. Options include ascending order (1, 2, 3…), descending order (3, 2, 1…), or alternating order (1, 3, 2, 4, 5…).

Paper size

This setting ensures that the collating machine uses the correct paper size for the documents being collated.

Paper orientation

This setting specifies whether the documents should be collated in portrait or landscape orientation.

Stapling

Some collating machines offer stapling options, allowing users to staple the collated sets together. This setting typically includes options for staple position (e.g., top left, top right) and staple type (e.g., standard, heavy-duty).

Folding

Certain collating machines can also fold the collated sets. This setting allows users to specify the fold type (e.g., half-fold, tri-fold) and fold direction (e.g., inward, outward).Optimizing these settings is crucial for efficient and accurate collating. For example, setting the correct number of copies ensures that each recipient receives the complete set of documents, while selecting the appropriate collating sequence ensures that the pages are in the correct order.

Proper paper size and orientation settings prevent misalignment or paper jams during the collating process. Stapling and folding settings add a professional touch to the collated sets, making them ready for distribution or presentation.

Collating Troubleshooting

Collating is a crucial step in the printing process, ensuring that the printed sheets are assembled in the correct order. However, various issues can arise during collating, leading to delays and reduced productivity. Understanding these problems and their solutions is essential for efficient operation.

Identifying Common Collating Problems

The most common collating problems include:

- Paper jams: Paper jams can occur due to various reasons, such as misaligned paper, worn-out rollers, or debris in the machine.

- Misfeeds: Misfeeds happen when the collator fails to pick up or feed the sheets correctly, resulting in skipped or duplicated pages.

- Skewed or wrinkled output: Skewed or wrinkled output occurs when the sheets are not aligned properly or are folded during the collating process.

Collating and Finishing

Collating is an essential step in the finishing process of printed materials. It involves gathering and assembling individual printed sheets into a specific order to create a complete document. Collating ensures that all pages are present, in the correct sequence, and properly oriented.Collating plays a crucial role in the overall finishing workflow.

It typically follows printing and precedes other finishing processes such as binding, trimming, and folding. By collating printed sheets before moving on to these subsequent steps, it helps ensure that the final product is complete and accurate.

Integrated Collating and Finishing Systems

Many modern printing and finishing systems incorporate integrated collating capabilities. These systems combine multiple processes into a single streamlined workflow, enhancing efficiency and reducing the risk of errors. For example, some high-speed digital printing presses have inline collating modules that automatically gather and stack printed sheets as they come off the press.Other integrated systems combine collating with other finishing processes, such as binding and trimming.

These systems can automatically collate printed sheets, bind them together, and trim the edges to create a finished product in one continuous operation. Such integrated systems are particularly useful for high-volume printing environments where speed and accuracy are critical.

Collating for Special Applications

Collating techniques are adaptable to meet the unique requirements of various document types. Specialized methods ensure efficient organization, easy retrieval, and protection of documents with varying characteristics.

Collating Techniques for Unique Document Types

| Document Type | Collating Technique | Benefits ||—|—|—|| Legal Documents | Tabbed collating | Facilitates quick identification and retrieval of specific sections within a document. || Medical Records | Sequential collating | Ensures chronological organization of patient records for efficient access.

Print collate is a printing function that arranges printed pages in the correct order before delivering them. It ensures that multi-page documents are assembled in the desired sequence. To prepare for print collate, it’s essential to understand how to put paper in a printer correctly.

By following the steps outlined here , you can ensure proper paper loading, which is crucial for successful print collate operations. Once the paper is correctly loaded, the print collate function can effectively organize the printed pages, making it easier to assemble and distribute multi-page documents.

|| Engineering Drawings | Folded collating | Protects delicate drawings from damage and enables convenient storage. |

Challenges and Solutions for Collating Non-Standard Documents

| Challenge | Solution ||—|—|| Varying Page Sizes | Adjustable or custom-sized collating trays accommodate different page sizes. || Varying Orientations | Software automatically detects and adjusts document orientation for consistent collating. || Non-Standard Binding Methods | Alternative binding options, such as loose-leaf binders or spiral binding, accommodate non-standard documents.

|

Case Studies of Innovative Collating Applications, What does print collate mean

- Automated collating system for a high-volume document processing center resulted in a 50% reduction in processing time.

- Custom collating solution for a medical research laboratory enabled efficient organization and retrieval of patient samples.

- Innovative collating technique for an engineering firm facilitated seamless collaboration on large-scale construction projects.

Collating for Accessibility

Collating documents for accessibility ensures individuals with disabilities can access and engage with information effectively. Accessible collated documents enable users to navigate, understand, and interact with content, regardless of their abilities or disabilities.

Assistive Technology Tools

Assistive technology tools, such as screen readers and text-to-speech software, assist individuals with visual or cognitive impairments in accessing digital documents. Collated documents should be structured and formatted in a way that is compatible with these tools.

Tagged PDFs

Tagged PDFs are electronic documents that include structural elements, such as headings, paragraphs, and tables. These tags provide assistive technology tools with information about the document’s structure, making it easier for users to navigate and understand the content.

Online Collaboration Tools

Online collaboration tools, such as Google Docs and Microsoft Word Online, allow multiple users to work on a document simultaneously. These tools often include features that promote accessibility, such as automatic tagging and the ability to add comments and annotations.

Print collating refers to the process of combining multiple printed pages in a specific order to create a complete document. It ensures that pages are assembled in the correct sequence and are ready for binding or distribution. While print collating is an essential step in document preparation, it’s important to consider the capabilities of your printer when printing on cardstock.

Can printers print on cardstock ? Understanding the limitations and recommendations for printing on cardstock will help ensure successful and high-quality printouts.

Accessibility Standards

Collated documents should meet accessibility standards to ensure they are accessible to individuals with disabilities. Key accessibility standards include:

- WCAG 2.1 (Web Content Accessibility Guidelines)

- Section 508 of the Rehabilitation Act

- ARIA (Accessible Rich Internet Applications)

Accessibility Features of Collating Methods

| Collating Method | Accessibility Features ||—|—|| Assistive Technology Tools | Screen readers, text-to-speech software || Tagged PDFs | Structural elements (headings, paragraphs, tables) || Online Collaboration Tools | Automatic tagging, comments, annotations |

Sample Accessible Collated Document

A sample accessible collated document should include the following features:

- Clear and concise headings

- Structured text with paragraphs and lists

- Alternative text for images

- Descriptive links

- Consistent and logical navigation

Collating Trends and Innovations

Collating technology is undergoing a significant transformation, driven by automation, machine learning, and cloud-based solutions. These advancements are revolutionizing document production, enabling faster, more efficient, and more secure processes.

Advancements in Collating Equipment and Software

Collating equipment and software have seen significant advancements in recent years. High-speed collators can now process thousands of documents per hour, while multi-function devices combine collating with other document processing tasks such as printing, scanning, and copying. Specialized software for document assembly automates the process of gathering and organizing documents from multiple sources.

Future of Collating

The future of collating is bright. Automation, machine learning, and cloud-based solutions will continue to drive innovation in this field. We can expect to see even faster and more efficient collating processes, as well as improved document security and accessibility.

Comparative Analysis of Collating Methods

There are three main types of collating methods: manual, semi-automated, and fully automated. Manual collating is the most labor-intensive method, but it is also the most flexible. Semi-automated collating uses machines to assist with the collating process, while fully automated collating uses machines to perform the entire process without human intervention.

- Manual collatingis the most labor-intensive method, but it is also the most flexible. This method is suitable for small batches of documents or for documents that require special handling.

- Semi-automated collatinguses machines to assist with the collating process. This method is faster than manual collating, but it is not as flexible. Semi-automated collating is suitable for medium-sized batches of documents.

- Fully automated collatinguses machines to perform the entire collating process without human intervention. This method is the fastest and most efficient, but it is also the most expensive. Fully automated collating is suitable for large batches of documents.

Key Trends and Innovations in Collating

The key trends and innovations in collating include:

- Increased automation: Automation is reducing the need for manual labor in the collating process. This is making collating faster, more efficient, and more accurate.

- Machine learning: Machine learning is being used to develop new collating algorithms that can improve the speed and accuracy of the process. Machine learning can also be used to identify and correct errors in the collating process.

- Cloud-based solutions: Cloud-based solutions are making it possible to access collating services from anywhere with an internet connection. This is making collating more convenient and flexible.

Conclusion

Collating is a critical part of the document production process. The latest trends and innovations in collating technology are making this process faster, more efficient, and more secure. As these trends continue to develop, we can expect to see even more innovation in the field of collating.

Collating in Different Industries

Collating is a vital process in various industries, including printing, publishing, and manufacturing. Each industry has specific requirements and challenges that influence the collating process.

Printing and Publishing

Collating is crucial in printing and publishing to ensure the correct order of pages in books, magazines, and other printed materials. High-speed collating machines are used to assemble large volumes of documents efficiently. Accurate collating is essential to prevent errors and maintain the integrity of the printed materials.

Manufacturing

In manufacturing, collating is used to assemble components and parts into finished products. For instance, in the automotive industry, collating is employed to gather various components for vehicle assembly. Automated collating systems are often used to streamline the process and ensure accuracy.

Healthcare

Collating plays a vital role in healthcare, particularly in the preparation of patient records, medical charts, and prescriptions. Accurate collating ensures that patients receive the correct information and medications, promoting patient safety and efficient healthcare delivery.

Other Industries

Collating is also used in other industries, such as logistics, retail, and education. In logistics, collating helps organize and prepare shipments for distribution. In retail, collating is used to assemble product orders for customers. In education, collating is employed to create student handouts, course materials, and other educational resources.

Collating Case Studies

Collating has revolutionized various industries by streamlining document assembly and enhancing productivity. Numerous successful implementations showcase the tangible benefits of collating solutions.

Challenge: Manual Collation Bottlenecks

A large healthcare provider struggled with manual collation of patient records, leading to delays and errors. The process involved gathering documents from multiple sources, manually collating them, and ensuring completeness.

Solution:The healthcare provider implemented an automated collating system that integrated with their electronic health records (EHR) system. The system automatically extracted patient documents, sorted them based on predefined rules, and collated them into complete sets.

Benefits:The automated collating system significantly reduced manual labor, improved accuracy, and accelerated the document preparation process. The healthcare provider reported a 75% reduction in collation time and a 99% increase in document accuracy.

Challenge: Inconsistent Document Quality

A financial services company faced challenges with inconsistent document quality due to manual collation. Documents were often missing pages, out of order, or contained errors.

Solution:The financial services company deployed a collating system that incorporated quality control checks. The system automatically verified the completeness and accuracy of documents, ensuring that only complete and error-free sets were collated.

Benefits:The collating system improved document quality, reduced the risk of errors, and enhanced customer satisfaction. The financial services company experienced a 95% reduction in customer complaints related to document quality.

Challenge: High Production Volumes

A manufacturing company required a high-volume collating solution to handle the assembly of complex product manuals. The manuals consisted of hundreds of pages and needed to be collated in specific sequences.

Solution:The manufacturing company invested in a high-speed collating machine that could handle large volumes and complex collation requirements. The machine utilized advanced sorting and stacking mechanisms to ensure accurate and efficient collation.

Benefits:The high-speed collating machine significantly increased production capacity, reduced labor costs, and improved the overall efficiency of the manual assembly process. The manufacturing company achieved a 60% increase in productivity and a 40% reduction in labor costs.

Collating Glossary

Collating involves gathering and arranging multiple printed sheets in the correct order to form a complete document. Here’s a glossary of key terms related to collating:

Collating: The process of gathering and arranging printed sheets in the correct order to form a complete document.

Collating Equipment

- Collator: A machine that gathers and arranges printed sheets in the correct order.

- Gatherer: A device that gathers printed sheets from multiple sources and combines them into sets.

- Stitcher: A machine that binds collated sheets together using staples or stitches.

- Trimmer: A machine that trims the edges of collated sheets to create a uniform size.

Collating Processes

- Jogging: Aligning the edges of a stack of printed sheets to ensure they are even.

- Shingling: Overlapping the edges of printed sheets to make them easier to gather.

- Inserting: Placing printed sheets into a collator or gatherer.

- Stitching: Binding collated sheets together using staples or stitches.

Collating Settings

- Collating sequence: The order in which printed sheets are gathered and arranged.

- Page count: The number of pages in a collated document.

- Set size: The number of collated sheets in a set.

- Binding type: The method used to bind collated sheets together (e.g., stapling, stitching).

Collating Troubleshooting

- Misfeeds: When printed sheets are not fed into the collator or gatherer correctly.

- Paper jams: When printed sheets become stuck in the collator or gatherer.

- Incorrect collation: When printed sheets are gathered and arranged in the wrong order.

- Missing sheets: When some printed sheets are missing from the collated document.

Collating and Finishing

- Folding: Creating creases in collated sheets to make them easier to read or store.

- Trimming: Cutting the edges of collated sheets to create a uniform size.

- Binding: Joining collated sheets together using various methods (e.g., stapling, stitching, gluing).

- Covering: Adding a cover to a collated document to protect it and improve its appearance.

Collating for Special Applications

- Variable data printing: Printing different data on each sheet of a collated document.

- Perfect binding: A high-quality binding method that creates a seamless spine.

- Saddle stitching: A binding method that uses staples to bind collated sheets along the center fold.

- Wire-o binding: A binding method that uses wire loops to bind collated sheets together.

Collating for Accessibility

- Accessible collating: Ensuring that collated documents are accessible to people with disabilities.

- Braille: A tactile writing system used by people who are blind or visually impaired.

- Large print: Text that is larger than standard size to make it easier to read.

- Audio description: A verbal description of visual content for people who are blind or visually impaired.

Collating Trends and Innovations

- Digital collating: Using software to collate electronic documents.

- Cloud-based collating: Using cloud-based services to collate documents remotely.

- Automated collating: Using automated systems to collate documents without manual intervention.

- Sustainable collating: Using environmentally friendly materials and processes in collating.

Collating in Different Industries

- Printing industry: Collating is a key process in the printing industry for producing books, magazines, and other printed materials.

- Publishing industry: Collating is used to assemble manuscripts, books, and other publications.

- Education industry: Collating is used to assemble учебные материалы, such as handouts, worksheets, and tests.

- Business industry: Collating is used to assemble presentations, reports, and other business documents.

Collating Case Studies

- Case study: Using digital collating to improve efficiency in a printing company

- Case study: Implementing automated collating in a publishing house

- Case study: Creating accessible collated documents for a university

- Case study: Using sustainable collating practices in a business environment

Collating Resources

Enhance your knowledge of collating with these valuable resources.

Industry Websites

- Printing Industries of America (PIA)

- National Association for Printing Leadership (NAPL)

- Specialty Graphic Imaging Association (SGIA)

Articles

- 5 Ways to Improve Your Collating Workflow

- Tips for Collating Large Documents

- How to Increase Collating Efficiency

Videos

- How to Collate Documents Using a Collator

- Collating Techniques for Different Types of Documents

- Troubleshooting Common Collating Problems

Additional Research and Professional Development

Consider these opportunities to deepen your knowledge and skills in collating:

- Attend industry conferences and workshops

- Enroll in online courses or certification programs

- Join professional organizations like PIA, NAPL, or SGIA

Collating Infographics

Collating infographics provide a visually engaging way to present key concepts related to collating. By using charts, graphs, and diagrams, infographics can make complex information easier to understand and digest. They can also be shared on social media and other platforms, helping to spread awareness about collating and its benefits.To create effective collating infographics, it is important to consider the following:

Design

* Use visually appealing designs that are eye-catching and engaging.

- Use clear and concise text that complements the visuals.

- Use high-quality images and graphics.

- Consider using interactive elements to enhance engagement.

- Create a consistent visual style for all infographics.

- Use appropriate fonts and colors to enhance readability and visual appeal.

Content

* Focus on key collating concepts, such as the different types of collating, the benefits of collating, and the various applications of collating.

- Use charts, graphs, and diagrams to illustrate complex information.

- Include real-life examples to make the information more relatable.

- Make the infographics shareable on social media and other platforms.

Accessibility

* Ensure that the infographics are accessible to users with disabilities.

- Use alt text to describe images and graphics.

- Use clear and concise language.

- Avoid using jargon or technical terms.

Testing

* Test the infographics with users to ensure effectiveness and clarity.

- Get feedback on the design, content, and accessibility of the infographics.

- Make changes based on the feedback to improve the infographics.

Collating Videos

Collating videos are a valuable tool for demonstrating collating processes and techniques. They can help viewers understand the different steps involved in collating, from gathering and organizing documents to stapling and finishing. Well-produced collating videos can be a great way to train new employees, refresh the skills of existing employees, or provide customers with a better understanding of your collating services.

Creating Effective Collating Videos

- Use high-quality footage.The footage in your collating videos should be clear and well-lit, with no shaky camera work or distracting background noise.

- Provide clear explanations.The narrator of your collating videos should speak clearly and concisely, explaining each step of the collating process in detail.

- Make the videos accessible.Your collating videos should be accessible to viewers with disabilities, including those who are deaf or hard of hearing. This means providing closed captions and transcripts for all of your videos.

Query Resolution

What are the advantages of machine collating over manual collating?

Machine collating offers several advantages over manual collating, including increased speed, accuracy, and efficiency. Machines can collate large volumes of documents quickly and precisely, reducing the risk of errors and saving valuable time.

What are some common problems that can occur during collating?

Common problems during collating include misfeeds, jams, and incorrect collation. Misfeeds occur when the machine fails to pick up a sheet of paper, while jams occur when sheets become stuck in the machine. Incorrect collation occurs when the pages are assembled in the wrong order.

How can I troubleshoot collating problems?

To troubleshoot collating problems, check for any obstructions in the paper path, ensure that the paper is properly loaded, and adjust the machine settings accordingly. If the problem persists, consult the machine’s user manual or seek professional assistance.