How to print on tissue paper is an intriguing and multifaceted topic that unveils the art of transforming delicate tissue into eye-catching prints. Embark on this journey as we delve into the intricacies of this process, exploring the materials, techniques, and considerations that empower you to create stunning designs on this delicate medium.

From selecting the appropriate printer and ink to mastering image preparation and troubleshooting common printing issues, this comprehensive guide provides a step-by-step roadmap for achieving exceptional results. Discover the versatility of printed tissue paper, its applications in gift wrapping, crafting, packaging, and marketing, and gain insights into the design principles that elevate your creations.

Materials Required

Printing on tissue paper necessitates specific materials to achieve optimal results.

Suitable Tissue Paper

- Thin and Lightweight:Choose tissue paper that is thin enough to absorb ink properly without smudging.

- Absorbent:Opt for tissue paper with good absorbency to prevent ink from bleeding through.

- Smooth Surface:A smooth surface ensures crisp and clear prints.

Printer and Ink

- Inkjet Printer:Inkjet printers are ideal for printing on tissue paper due to their ability to deliver precise ink droplets.

- Sublimation Printer:Sublimation printers use heat to transfer ink onto the tissue paper, resulting in vibrant and durable prints.

- Pigment Ink:Pigment inks are recommended as they are water-resistant and produce sharper prints.

Additional Tools and Materials

- Craft Knife or Scissors:For trimming and cutting the tissue paper.

- Rulers or Measuring Tape:For precise measurements and alignment.

- Drying Rack:To hang the printed tissue paper for drying.

Printer Setup

Before printing on tissue paper, it is crucial to ensure that your printer is correctly set up to accommodate the delicate nature of the material.

Selecting Appropriate Printer Settings

Most modern printers offer a range of settings specifically designed for different types of paper. When printing on tissue paper, select the “Fine” or “Photo” setting to minimize smudging and ensure optimal ink absorption. Additionally, adjust the print quality to “High” to produce sharp and vibrant prints.

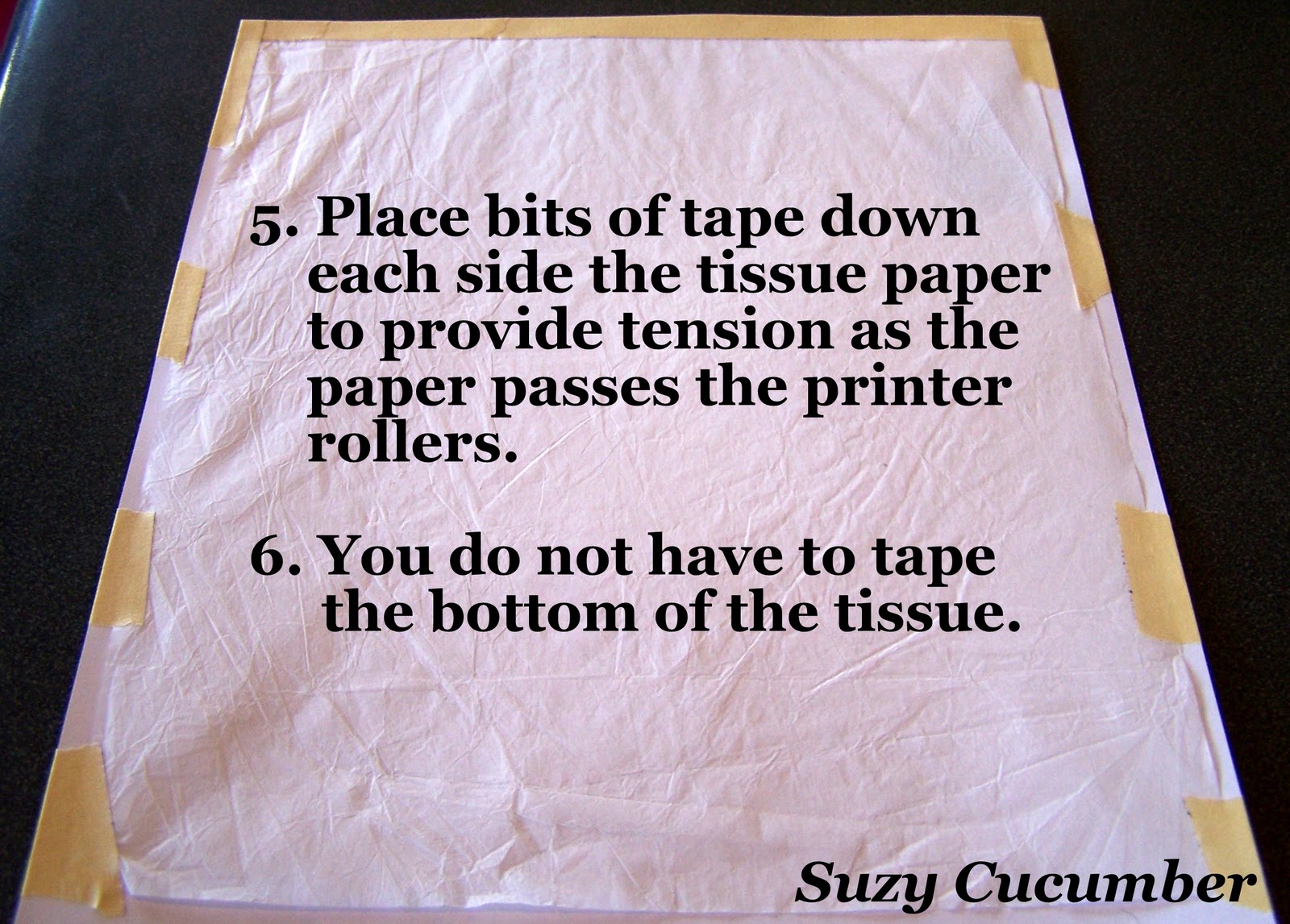

Adjusting Printer Tray

To prevent tissue paper from tearing or jamming during printing, it is essential to adjust the printer tray accordingly. Gently lift the paper tray and extend the paper guides to the edges of the tissue paper stack. Ensure that the guides are not too tight to avoid creasing or bending the paper.

Feeding Tissue Paper

Tissue paper tends to be thin and delicate, so it is important to feed it carefully into the printer. Flatten the stack of tissue paper before loading it into the tray to prevent uneven feeding. Avoid overfilling the tray, as this can lead to paper jams.

Gently guide the tissue paper into the printer using your fingers to prevent tearing or smudging.

Image Preparation

Proper image preparation is crucial for successful tissue paper printing. The following guidelines will ensure optimal results:

Image Resolution:For high-quality prints, use images with a resolution of at least 300 dpi (dots per inch). This ensures crisp and clear images without pixelation.

File Format:Save images in a lossless file format such as TIFF or PNG. These formats preserve image quality without compression, which can degrade the image.

Printing on tissue paper requires specialized techniques due to its delicate nature. While some may question whether printer ink dries out during this process ( does printer ink dry out ), it is essential to consider the type of ink and printer used.

By understanding the properties of the ink and the printing process, you can ensure successful and vibrant prints on tissue paper.

Adjusting Brightness and Contrast

Adjusting brightness and contrast can enhance image visibility on tissue paper. Increase brightness to lighten the image and improve detail in dark areas. Adjust contrast to define edges and enhance overall image sharpness.

Resizing and Cropping Images

Resize images to fit the desired print size while maintaining the original aspect ratio. Cropping allows you to focus on specific areas of the image and remove unnecessary elements.

Printing Process

Printing on tissue paper requires careful handling and precise settings to achieve optimal results. The printing process involves several crucial steps, including loading the tissue paper into the printer, selecting appropriate print quality settings, and ensuring proper alignment and handling.

To begin the printing process, the tissue paper must be carefully loaded into the printer. The specific method of loading may vary depending on the printer model. However, it is generally recommended to use a manual feed tray to avoid damaging the delicate tissue paper.

The tissue paper should be placed in the tray with the printable side facing up and should be gently aligned to ensure proper printing.

Print Quality Settings

After loading the tissue paper, the print quality settings should be adjusted to optimize the printing results. The print quality settings can be accessed through the printer’s control panel or software interface. The following settings are particularly important for printing on tissue paper:

- Paper Type:Select the “Tissue Paper” option or the closest available setting that matches the type of tissue paper being used.

- Print Resolution:Choose a higher print resolution (e.g., 1200 dpi or higher) to ensure sharp and detailed prints.

- Ink Type:Use pigmented inks or dye-based inks that are specifically designed for printing on tissue paper.

- Print Speed:Reduce the print speed to allow the ink to dry properly and prevent smudging.

It is important to note that the optimal print quality settings may vary depending on the specific printer model and the type of tissue paper being used. Experimentation and adjustments may be necessary to achieve the desired results.

Troubleshooting

When printing on tissue paper, several common issues can arise. Understanding these issues and their solutions can help ensure a successful printing process.

Common printing problems include smudging, ink bleeding, and misalignment. These issues can be caused by various factors, such as improper printer settings, inadequate ink absorption, or misalignment of the print head.

Resolving Printing Issues

Smudging and Ink Bleeding

- Cause:Insufficient ink absorption by the tissue paper.

- Solution:Use high-quality tissue paper specifically designed for printing or apply a thin layer of clear acrylic spray to the printed surface to seal the ink.

Misalignment

- Cause:Misalignment of the print head or incorrect printer settings.

- Solution:Check the printer’s alignment settings and adjust them if necessary. Ensure the tissue paper is properly loaded into the printer.

Preventing Print Errors

- Use high-quality tissue paper specifically designed for printing.

- Ensure the printer is properly calibrated and maintained.

- Load the tissue paper correctly into the printer.

- Test print on a small piece of tissue paper before printing the final product.

- Allow the ink to dry completely before handling the printed tissue paper.

Applications of Tissue Paper Printing

Printed tissue paper offers a versatile range of applications beyond its primary use as a protective wrapping material. Its vibrant designs and customization options make it a creative and effective medium for various purposes.

Gift Wrapping

Printed tissue paper elevates the presentation of gifts, adding a touch of elegance and personalization. Its lightweight and delicate texture gently cushions delicate items, while its vibrant prints create an eye-catching visual appeal.

Crafting

In the realm of crafting, printed tissue paper becomes a versatile material for creating unique and decorative projects. Its thin and pliable nature allows for intricate folding, cutting, and decoupage techniques, inspiring imaginative creations such as paper flowers, garlands, and ornaments.

Packaging

Printed tissue paper serves as an aesthetically pleasing and protective packaging solution for a wide range of products. Its delicate touch provides a layer of cushioning, while its vibrant prints enhance the overall presentation. From delicate jewelry to luxurious perfumes, printed tissue paper adds a touch of sophistication and exclusivity to packaging.

Marketing and Branding

Businesses leverage printed tissue paper as a cost-effective and impactful marketing tool. Custom designs featuring logos, brand colors, and promotional messages can create a lasting impression on customers. By incorporating printed tissue paper into packaging and gift wrapping, businesses reinforce their brand identity and increase visibility.

Design Considerations

The design of your tissue paper print plays a crucial role in determining its visual appeal and effectiveness. Here are some important considerations to keep in mind:

High-Quality Images: Using high-quality images is essential for producing sharp and vibrant prints. Low-resolution images will result in pixelated and blurry prints that lack detail and clarity.

Color and Contrast

The colors and contrast of your design have a significant impact on the overall look and readability of the printed tissue paper. Bright and contrasting colors create a bold and eye-catching effect, while subtle and muted colors can convey a more elegant or understated tone.

It’s important to consider the color of the tissue paper itself when selecting your design colors. For example, printing dark colors on light-colored tissue paper will result in a more vibrant and visible print, while printing light colors on dark tissue paper may require additional layers of ink to achieve the desired opacity.

Creating Eye-Catching Designs

To create eye-catching and visually appealing designs, consider the following tips:

- Use bold and simple fonts that are easy to read, even from a distance.

- Incorporate high-quality images or graphics that are relevant to your message or brand.

- Experiment with different colors and patterns to create a unique and memorable design.

- Consider the overall layout and composition of your design to ensure it is balanced and visually appealing.

Examples of Effective and Ineffective Design Elements

Here are some examples of effective and ineffective design elements for tissue paper printing:

- Effective:Using high-resolution images with bright and contrasting colors.

- Ineffective:Using low-resolution images with dull and muted colors.

- Effective:Incorporating a bold and easy-to-read headline.

- Ineffective:Using a small and difficult-to-read font.

- Effective:Creating a balanced and visually appealing layout.

- Ineffective:Cluttering the design with too many elements.

Tools and Resources for Creating Professional-Looking Designs

There are a variety of tools and resources available to help you create professional-looking designs for tissue paper printing. Here are a few recommendations:

- Adobe Photoshop:A powerful image editing and design software that allows you to create high-quality images and graphics.

- Canva:An online graphic design platform that offers a wide range of templates and tools for creating eye-catching designs.

- GIMP:A free and open-source image editing software that provides a comprehensive set of features for creating and editing images.

Ink Types

The choice of ink for tissue paper printing is crucial to ensure optimal results. Different types of ink possess unique characteristics that influence their suitability for specific printing needs. This section provides an overview of the various ink types, their advantages, disadvantages, and guidance on selecting the best ink for your project.

Factors to consider when selecting ink for tissue paper printing include drying time, colorfastness, environmental impact, and cost.

Dye-Based Inks

Dye-based inks are widely used in inkjet printing and are known for their vibrant colors and affordability. They are composed of water-soluble dyes that penetrate the tissue paper fibers, resulting in excellent color reproduction.

- Advantages:Vibrant colors, affordable, widely available

- Disadvantages:Slow drying time, susceptible to fading and water damage

Pigment-Based Inks

Pigment-based inks contain solid particles of pigment that adhere to the surface of the tissue paper. They offer superior colorfastness and water resistance compared to dye-based inks.

- Advantages:Excellent colorfastness, water-resistant, durable

- Disadvantages:Slower drying time, may produce less vibrant colors

Sublimation Inks

Sublimation inks are specialized inks used in a unique printing process called sublimation printing. These inks transform from a solid to a gas when heated, bonding with the fibers of the tissue paper. Sublimation inks produce high-quality, durable prints with excellent color accuracy.

- Advantages:Vibrant colors, durable, water-resistant

- Disadvantages:Requires specialized equipment, higher cost

Comparison Table of Ink Types

The following table summarizes the key characteristics of each ink type discussed:

| Ink Type | Drying Time | Colorfastness | Environmental Impact | Cost |

|---|---|---|---|---|

| Dye-Based | Slow | Low | Low | Affordable |

| Pigment-Based | Slower | High | Moderate | Moderate |

| Sublimation | Fast | High | Moderate | Higher |

Paper Thickness

The thickness of tissue paper significantly influences the printing process and the final results. Thicker tissue paper is more robust and can withstand the printing process better, while thinner paper is more delicate and prone to tearing or wrinkling. Understanding the impact of paper thickness is crucial for selecting the appropriate paper for the desired results.

Choosing the Appropriate Paper Thickness

The choice of paper thickness depends on several factors, including the type of printer used, the desired print quality, and the intended application. For inkjet printers, thicker tissue paper (around 15-20 gsm) is generally recommended to prevent ink bleeding and smudging.

Laser printers, on the other hand, can handle thinner paper (around 10-15 gsm) without compromising print quality.

Handling and Storing Tissue Paper of Varying Thicknesses

Tissue paper of varying thicknesses requires careful handling and storage to maintain its integrity. Thicker paper can be handled more roughly, while thinner paper requires more delicate handling to avoid tearing. Store tissue paper in a cool, dry place away from direct sunlight and moisture to prevent warping or damage.

Printing Techniques

Various printing techniques are employed for tissue paper, each with unique advantages and disadvantages. Understanding these techniques helps in selecting the most suitable method for specific needs.

Flexography

- Uses flexible printing plates made of rubber or photopolymer.

- Suitable for high-speed printing of large volumes.

- Produces sharp and vibrant prints with good ink coverage.

- Limitations include lower resolution compared to other techniques.

Offset Lithography

- Involves transferring the image from a metal plate to a rubber roller, then to the tissue paper.

- Delivers high-quality prints with excellent color accuracy and detail.

- Suitable for medium to large print runs.

- Requires longer setup times and is more expensive than flexography.

Digital Printing

- Uses inkjet or laser technology to directly print the image onto the tissue paper.

- Offers fast turnaround times and is suitable for short-run printing.

- Provides high-resolution prints with variable data capabilities.

- Can be more expensive than traditional printing methods.

Gravure Printing

- Involves etching the image into a metal cylinder, which is then filled with ink and transferred to the tissue paper.

- Produces high-quality prints with excellent detail and color reproduction.

- Suitable for large print runs and long-lasting prints.

- Requires specialized equipment and is more expensive than other techniques.

Screen Printing

- Uses a mesh screen to transfer ink onto the tissue paper.

- Suitable for printing thick layers of ink, creating raised or textured effects.

- Offers versatility in terms of ink types and substrates.

- Can be slower and less precise than other techniques.

Sustainability: How To Print On Tissue Paper

Printing on tissue paper has environmental implications that need to be addressed to promote sustainability in the industry. Understanding the impact of tissue paper production and printing practices on the environment is crucial for adopting responsible measures.

The production of tissue paper involves deforestation, water consumption, and greenhouse gas emissions. Deforestation occurs to obtain raw materials for paper production, while water is used extensively in the pulping and bleaching processes. Additionally, the manufacturing process releases greenhouse gases, contributing to climate change.

Reducing Waste and Promoting Sustainability

To reduce waste and promote sustainability in tissue paper printing, several measures can be implemented:

- Use recycled paper:Opting for recycled tissue paper reduces the demand for virgin materials and conserves natural resources.

- Optimize ink usage:Employing efficient printing techniques and optimizing ink usage minimizes waste and reduces the environmental impact of ink production.

- Implement efficient printing practices:Adopting eco-friendly printing practices, such as double-sided printing and reducing print runs, can conserve resources and reduce waste.

Recycling and Disposal

Recycling and proper disposal of used tissue paper are essential for sustainability:

- Home recycling:In home settings, used tissue paper can be recycled through municipal recycling programs or composted if biodegradable.

- Industrial recycling:Large-scale tissue paper users, such as hospitals and offices, can implement industrial recycling programs to recover and reuse waste paper.

- Proper disposal:Tissue paper should not be flushed down toilets as it can clog plumbing systems. Instead, it should be disposed of in designated waste containers.

Initiatives and Consumer Choices

Organizations and initiatives are actively working to reduce the environmental impact of tissue paper printing:

- Forest Stewardship Council (FSC):FSC certifies forests that meet sustainability standards, ensuring responsible sourcing of raw materials for paper production.

- Sustainable Tissue Paper Alliance (STPA):STPA promotes sustainable practices in the tissue paper industry, including responsible sourcing, water conservation, and waste reduction.

Consumer choices play a significant role in promoting sustainability in the tissue paper industry. By choosing products made from recycled materials, supporting eco-friendly printing practices, and recycling used tissue paper, consumers can contribute to reducing the environmental impact of the industry.

Emerging Technologies and Innovations

Emerging technologies and innovative solutions can further enhance sustainability in the printing process:

- Digital printing:Digital printing reduces waste by eliminating the need for printing plates and allowing for on-demand printing.

- Waterless printing:Waterless printing techniques use alternative methods to traditional water-based printing, reducing water consumption.

- Biodegradable inks:Biodegradable inks minimize the environmental impact of ink production and disposal.

By adopting sustainable practices, promoting responsible sourcing, and embracing emerging technologies, the tissue paper printing industry can reduce its environmental impact and contribute to a more sustainable future.

Safety Precautions

When working with tissue paper for printing purposes, it is essential to adhere to safety precautions to prevent accidents or injuries.

Printing on tissue paper requires a delicate touch and specialized techniques. While the profitability of print-on-demand services remains a topic of debate, with insights available at is print on demand profitable , the process of printing on tissue paper involves carefully selecting the right ink and paper combination, ensuring proper drying time, and using a gentle touch to avoid tearing the delicate material.

Potential Hazards:

- Flammability:Tissue paper is highly flammable and can easily ignite if exposed to heat sources. This poses a significant fire hazard, especially in enclosed spaces.

- Paper Cuts:Handling sharp printing materials, such as razor blades or paper cutters, can lead to paper cuts and other injuries if not handled carefully.

Safety Precautions:

- Keep printing materials away from heat sources:Never place tissue paper or other printing materials near open flames, heaters, or other heat sources to prevent accidental ignition.

- Wear gloves and safety glasses:When handling sharp materials, always wear protective gloves and safety glasses to minimize the risk of cuts or eye injuries.

- Ensure proper ventilation:Printing processes can release fumes or gases, so it is important to work in a well-ventilated area to prevent the inhalation of harmful substances.

Proper Handling and Storage:

- Storage conditions:Store tissue paper in a cool, dry place away from direct sunlight or moisture to prevent damage or deterioration.

- Safe handling:Always handle printing materials carefully to avoid spills or accidents. Keep them away from children and pets to prevent accidental ingestion or injury.

Cost Considerations

Printing on tissue paper involves various cost factors that need to be considered to optimize project expenses. These include:

Paper Type and Quality, How to print on tissue paper

The type and quality of tissue paper significantly impact the printing cost. Higher-quality paper with a smoother surface and higher basis weight (thickness) generally costs more than lower-quality paper.

Ink Type and Coverage

The type of ink used and the coverage area affect the cost. Solvent-based inks are typically more expensive than water-based inks. Additionally, printing with full-color coverage costs more than printing with a single color or black and white.

Printing Method

The printing method chosen, such as offset printing, digital printing, or screen printing, influences the cost. Offset printing is often more cost-effective for large quantities, while digital printing is suitable for smaller runs.

Order Quantity

The number of prints ordered directly affects the cost. Ordering in bulk usually results in lower per-unit costs.

Shipping Costs

Shipping costs vary depending on the quantity, weight, and destination of the printed tissue paper. Larger orders and longer shipping distances generally incur higher shipping costs.

Estimating Printing Costs

To estimate the cost of a printing project, consider the following steps:

- Calculate the number of prints needed.

- Determine the printing method and paper type based on the project requirements.

- Obtain quotes from multiple printers to compare pricing.

Tips for Saving Money on Printing Costs

- Use recycled paper or paper with a lower basis weight.

- Print in black and white instead of color.

- Order in bulk to take advantage of volume discounts.

- Negotiate with printers for discounts or special rates.

- Utilize online printing services or comparison websites to find the most competitive pricing.

Legal Considerations

Adhering to legal considerations is crucial when printing on tissue paper. Understanding copyright and intellectual property laws is essential to avoid any infringement issues.

If you intend to print copyrighted material, it’s imperative to obtain the necessary permissions from the copyright holder. Failure to do so may result in legal consequences.

Obtaining Permissions

To obtain permission to print copyrighted material, you can follow these steps:

- Identify the copyright holder: Determine who owns the copyright to the material you wish to print.

- Contact the copyright holder: Reach out to the copyright holder and request permission to use their copyrighted material.

- Negotiate terms: Discuss the terms of use, including the scope of the permission, duration, and any applicable fees.

- Obtain a written agreement: Secure a written agreement that Artikels the terms of use and protects both parties’ rights.

Clarifying Questions

What types of tissue paper are suitable for printing?

For optimal results, choose tissue paper specifically designed for printing, which is typically thicker and more durable than regular tissue paper.

Can I use any printer to print on tissue paper?

Not all printers are equipped to handle the delicate nature of tissue paper. Look for printers with a manual feed option and adjustable settings for paper thickness.

How do I prevent smudging or ink bleeding when printing on tissue paper?

Use high-quality ink designed for tissue paper printing and allow ample drying time before handling the prints to prevent smudging. Adjust the printer settings to reduce ink flow and avoid oversaturation.