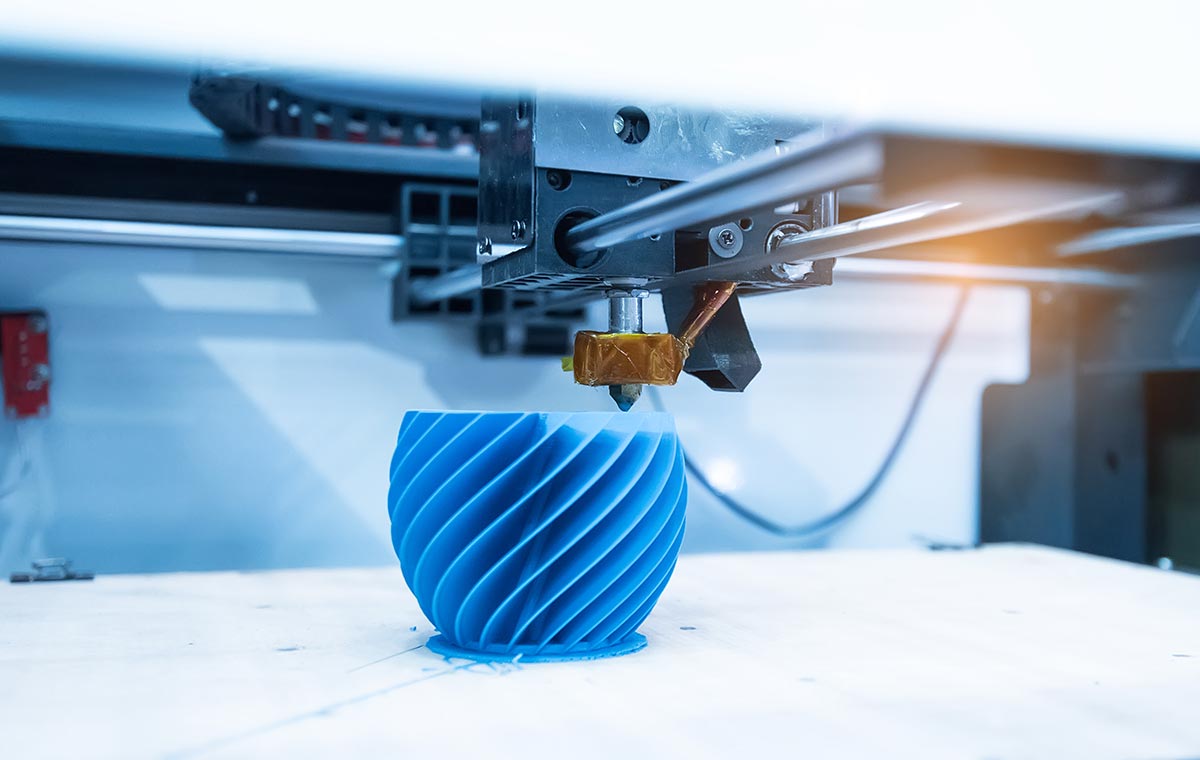

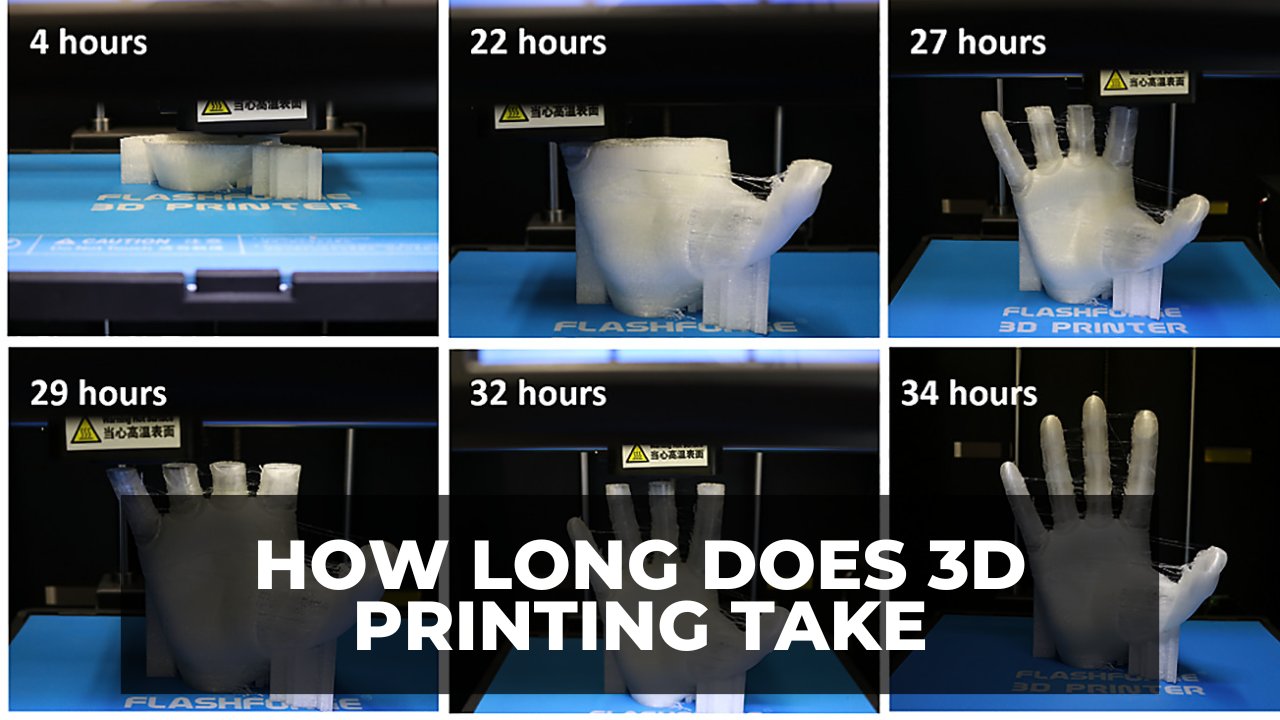

How long does it take to 3D print? This intriguing question marks the beginning of our exploration into the captivating world of 3D printing. We embark on a journey to unravel the intricate factors that influence print time, empowering you with the knowledge to optimize your 3D printing process for maximum efficiency.

From understanding the impact of model size, layer height, infill density, and print speed to delving into advanced techniques like using multiple nozzles and dissolvable supports, this comprehensive guide will equip you with a wealth of practical tips and insights to accelerate your 3D printing endeavors.

Print Time Estimation

Print time in 3D printing is influenced by several factors, including model size, layer height, infill density, print speed, nozzle size, and extrusion width. Understanding these factors can help you estimate print times and optimize your printing process.

Model Size

Larger models require more material and take longer to print. The volume of the model directly affects the print time, with larger volumes resulting in longer print times.

Layer Height

Layer height refers to the thickness of each layer deposited during printing. Thinner layers result in smoother surfaces but increase print time. Conversely, thicker layers reduce print time but may compromise surface quality.

Infill Density

Infill density determines the amount of material used to fill the interior of the model. Higher infill densities increase print time but provide stronger parts. Lower infill densities reduce print time but may result in weaker parts.

Print Speed

Print speed refers to the rate at which the printer extrudes material. Higher print speeds reduce print time but may compromise print quality. Lower print speeds increase print time but produce higher-quality prints.

Nozzle Size and Extrusion Width

The nozzle size and extrusion width affect the amount of material deposited per layer. Larger nozzles and wider extrusion widths result in faster print times but may reduce print resolution. Smaller nozzles and narrower extrusion widths produce higher-resolution prints but increase print time.

| Model Size (mm) | Model Complexity | Print Time (hours) |

|---|---|---|

| 100 x 100 x 100 | Simple | 2-4 |

| 100 x 100 x 100 | Moderate | 4-8 |

| 100 x 100 x 100 | Complex | 8-12 |

| 200 x 200 x 200 | Simple | 8-12 |

| 200 x 200 x 200 | Moderate | 12-18 |

| 200 x 200 x 200 | Complex | 18-24 |

Layer Height Optimization

Layer height, the thickness of each layer deposited during 3D printing, plays a significant role in determining print time. Generally, thicker layers result in faster printing times, while thinner layers lead to longer print times.

The trade-off between print quality and time savings is a key consideration when choosing a layer height. Thicker layers can lead to visible layer lines on the printed object, while thinner layers produce smoother surfaces with less visible layer lines.

However, thinner layers also increase printing time.

Impact of Layer Height on Print Time

The following table illustrates the impact of layer height on print time for a given object:

| Layer Height (mm) | Print Time (hours) |

|---|---|

| 0.2 | 10 |

| 0.1 | 15 |

| 0.05 | 20 |

Key Takeaways

The key takeaways from this analysis are:

- Thicker layers result in faster printing times.

- Thinner layers produce smoother surfaces with less visible layer lines.

- The optimal layer height depends on the specific requirements of the print job.

Recommendation

For prints where surface quality is critical, such as for presentation models or artistic objects, a thinner layer height is recommended to minimize visible layer lines. For prints where speed is more important, such as for functional parts or prototypes, a thicker layer height can be used to reduce printing time.

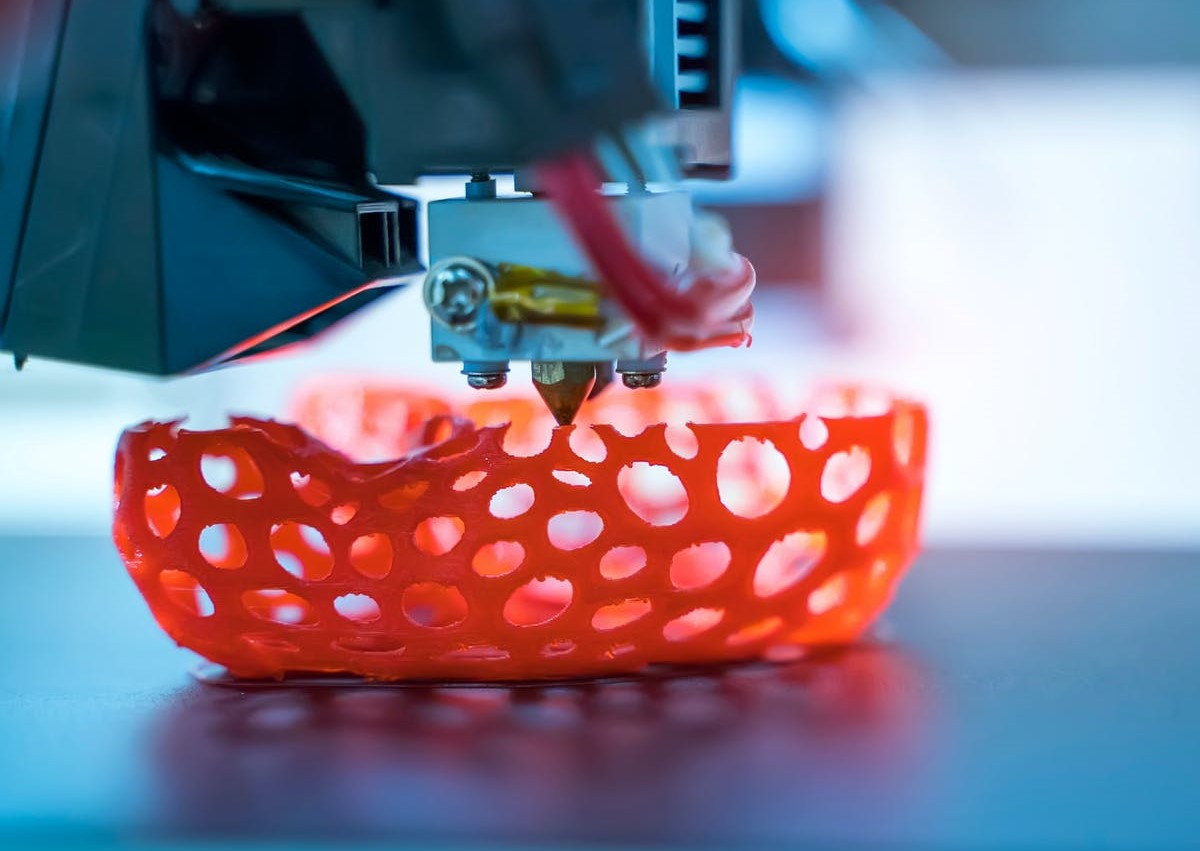

Infill Density Considerations

Infill density, a critical parameter in 3D printing, significantly influences both print time and structural strength of the printed object.

Infill patterns refer to the internal structure of the printed object, determining how the material is deposited within the outer shell. Common patterns include:

- Grid: Regular, cross-hatched pattern, offering moderate strength and printability.

- Triangular: Triangular-shaped infill, providing good strength and printability.

- Honeycomb: Hexagonal-shaped infill, maximizing strength while minimizing material usage.

- Concentric: Circular infill, ideal for curved surfaces and providing good strength.

- Gyroid: Complex, organic-shaped infill, offering exceptional strength and impact resistance.

The choice of infill pattern depends on the desired strength and printability characteristics of the object. Grid and triangular patterns offer a balance between strength and printability, while honeycomb and gyroid patterns provide superior strength for demanding applications.

Infill density, expressed as a percentage, represents the amount of material used to fill the internal volume of the object. Higher infill densities result in stronger objects but increase print time and material consumption.

| Infill Density (%) | Print Time (minutes) |

|---|---|

| 20 | 60 |

| 40 | 90 |

| 60 | 120 |

| 80 | 150 |

| 100 | 180 |

The optimal infill density varies depending on the application. For non-functional objects, low infill densities (20-40%) suffice. For structural components, higher infill densities (60-80%) enhance strength and durability. Critical parts or objects subject to significant loads may require 100% infill density for maximum strength.

Print Speed Optimization

Print speed is a crucial factor that significantly impacts print time, quality, and energy consumption. Understanding the factors that affect print speed and optimizing them for specific materials and print geometries is essential for efficient 3D printing.

Several factors influence print speed, including nozzle temperature, bed temperature, acceleration settings, layer height, and infill density. The nozzle temperature determines the material’s flowability, while the bed temperature affects the material’s adhesion to the print bed. Acceleration settings control the speed at which the print head moves, and layer height and infill density influence the amount of material deposited.

Impact of Print Speed on Print Time, Quality, and Energy Consumption

Increasing print speed can significantly reduce print time, but it can also affect print quality and energy consumption. Higher print speeds may lead to reduced layer adhesion, increased surface roughness, and potential print failures. Additionally, higher speeds require more energy to operate the printer.

| Print Speed | Print Time | Print Quality | Energy Consumption |

|---|---|---|---|

| Low | High | Good | Low |

| Medium | Moderate | Moderate | Moderate |

| High | Low | Poor | High |

The optimal print speed depends on the specific material, print geometry, and desired quality level. For example, materials with low flowability may require lower print speeds to ensure proper adhesion, while materials with high flowability can be printed at higher speeds.

Best Practices for Print Speed Optimization

To optimize print speed, consider the following best practices:

- For materials with low flowability, use lower print speeds to prevent under-extrusion and poor layer adhesion.

- For materials with high flowability, higher print speeds can be used to reduce print time without compromising quality.

- For complex geometries with intricate details, lower print speeds may be necessary to ensure accurate printing.

- For large, flat surfaces, higher print speeds can be used to reduce print time without significantly affecting quality.

- Monitor print progress and adjust print speed during printing if necessary. If the print quality is poor, reduce the print speed. If the print time is too long, increase the print speed.

Optimizing print speed can significantly improve the efficiency and quality of 3D printing. By understanding the factors that affect print speed and applying the best practices discussed above, users can achieve optimal results for their specific printing needs.

Potential Implications of Print Speed on Post-Processing Requirements

Print speed can also impact post-processing requirements. Higher print speeds may result in increased surface roughness, which may require additional sanding or smoothing to achieve the desired surface finish. Additionally, higher print speeds can lead to increased warping, which may require additional post-processing steps to correct.

Nozzle Size and Extrusion Width

Nozzle size and extrusion width play a significant role in determining the print time of a 3D print. Nozzle size refers to the diameter of the opening at the tip of the extruder through which the molten filament is deposited.

Extrusion width, on the other hand, is the width of the material deposited by the nozzle during a single pass.

Advantages and Disadvantages of Different Nozzle Sizes

Smaller nozzles (e.g., 0.2mm) produce finer details and smoother surfaces, but they also result in longer print times due to the reduced material flow rate. Larger nozzles (e.g., 0.4mm or 0.6mm) allow for faster printing, but may result in less detailed prints with more visible layer lines.

Print Time Comparison for Different Nozzle Sizes and Extrusion Widths

| Nozzle Size (mm) | Extrusion Width (mm) | Print Time (hours) |

|---|---|---|

| 0.2 | 0.2 | 10 |

| 0.2 | 0.3 | 8 |

| 0.4 | 0.4 | 5 |

| 0.4 | 0.6 | 4 |

| 0.6 | 0.6 | 3 |

Model Orientation

The orientation of a model can significantly impact the print time. Slicing software can optimize the orientation to minimize the print time by considering factors such as the model’s geometry, the printer’s capabilities, and the desired print quality.

Impact of Model Orientation on Print Time

The print time is affected by the following factors related to model orientation:

- Layer height:The layer height determines the thickness of each layer printed. A smaller layer height results in a smoother surface finish but increases the print time.

- Infill density:The infill density determines the amount of material used to fill the interior of the model. A higher infill density increases the print time.

- Print speed:The print speed determines the rate at which the printer extrudes the material. A higher print speed reduces the print time but can compromise the print quality.

- Nozzle size and extrusion width:The nozzle size and extrusion width determine the amount of material extruded per unit length. A larger nozzle size and extrusion width increase the print speed but can reduce the print quality.

Optimizing Model Orientation for Faster Printing

Slicing software can optimize the model orientation to minimize the print time by considering the following factors:

- Model geometry:The software analyzes the model’s geometry to determine the optimal orientation for printing. It considers factors such as the model’s size, shape, and complexity.

- Printer capabilities:The software takes into account the printer’s capabilities, such as the build volume, nozzle size, and print speed.

- Desired print quality:The software considers the desired print quality to determine the optimal layer height and infill density.

Examples of Model Orientation Impact on Print Time

The following table shows the impact of different orientations on print time for various model shapes:

| Model Shape | Orientation | Print Time |

|---|---|---|

| Cube | Flat on the build plate | Shortest |

| Cube | Standing upright | Longest |

| Cylinder | Lying on its side | Shortest |

| Cylinder | Standing upright | Longest |

| Sphere | Any orientation | Approximately equal |

Flowchart for Choosing Optimal Model Orientation

The following flowchart illustrates the decision-making process for choosing the optimal model orientation:

- Start:Load the model into the slicing software.

- Analyze model geometry:Determine the model’s size, shape, and complexity.

- Consider printer capabilities:Determine the printer’s build volume, nozzle size, and print speed.

- Set desired print quality:Determine the desired layer height and infill density.

- Optimize orientation:Use the slicing software to optimize the model orientation for the given criteria.

- End:Export the optimized model for printing.

Code Snippet for Automatic Model Orientation

The following Python script demonstrates how to use a Python script to automatically orient models for optimal printing:

“`pythonimport numpy as npimport trimeshdef optimize_model_orientation(model_path, printer_capabilities, desired_print_quality): “””Optimizes the orientation of a model for faster printing. Args: model_path: The path to the model file. printer_capabilities: A dictionary containing the printer’s capabilities.

desired_print_quality: A dictionary containing the desired print quality settings. Returns: The optimized model orientation. “”” # Load the model. model = trimesh.load(model_path) # Analyze the model geometry. model_size = model.bounding_box.extents model_shape = model.convex_hull.shape # Consider the printer capabilities.

build_volume = printer_capabilities[“build_volume”] nozzle_size = printer_capabilities[“nozzle_size”] print_speed = printer_capabilities[“print_speed”] # Set the desired print quality. layer_height = desired_print_quality[“layer_height”] infill_density = desired_print_quality[“infill_density”] # Optimize the orientation. orientation = optimize_orientation(model, build_volume, nozzle_size, print_speed, layer_height, infill_density) # Return the optimized orientation.

return orientation“`

Slicing Software Settings

Slicing software settings play a crucial role in determining print time. Optimizing these settings for specific models and printers can significantly reduce print times while maintaining print quality.

Different slicing software programs offer a range of settings that can affect print time, including layer height, infill density, print speed, nozzle size, extrusion width, and model orientation.

3D printing time varies based on the size, complexity, and material used. However, understanding printing terms can enhance the process. For instance, collating in printing refers to assembling printed pages in the correct order, which can impact the overall time it takes to complete a 3D print job.

Layer Height

Layer height refers to the thickness of each layer deposited by the printer. Thicker layers result in faster print times, but may compromise print quality and surface finish. Conversely, thinner layers produce smoother surfaces and finer details, but increase print time.

Infill Density

Infill density determines the amount of material used to fill the interior of the model. Higher infill densities result in stronger parts but increase print time. Conversely, lower infill densities reduce print time but may weaken the part.

Print Speed

Print speed is self-. Higher print speeds reduce print time, but may compromise print quality and increase the risk of errors. Conversely, lower print speeds produce higher quality prints but increase print time.

Nozzle Size and Extrusion Width

Nozzle size and extrusion width affect the amount of material deposited per layer. Larger nozzles and wider extrusion widths result in faster print times, but may produce less precise prints. Conversely, smaller nozzles and narrower extrusion widths produce more precise prints but increase print time.

Model Orientation

Model orientation refers to the way the model is positioned on the print bed. Optimizing model orientation can reduce print time by minimizing the amount of support material required and the number of layers needed to print the model.

Printer Hardware

The type of 3D printer used can significantly impact print time. Different printers have varying features that affect the speed at which they can produce prints.

Factors to consider include build volume, print speed, and nozzle temperature range.

Build Volume

Build volume refers to the maximum size of the object that can be printed on a particular printer. Larger build volumes allow for larger prints, but they also tend to increase print times.

The duration of 3D printing can vary greatly depending on several factors. To gain a comprehensive understanding of 3D printing and its timeline, it is recommended to explore resources such as a to z printing. This comprehensive guide provides valuable insights into the entire process, including factors that influence printing time and techniques for optimizing it.

Print Speed

Print speed is measured in millimeters per second (mm/s). Higher print speeds reduce print times, but they can also compromise print quality.

Nozzle Temperature Range

The nozzle temperature range determines the types of materials that can be printed. Higher nozzle temperatures allow for faster printing of certain materials, such as ABS.

The following table compares print times for different printer models:

| Printer Model | Build Volume (mm) | Print Speed (mm/s) | Nozzle Temperature Range (°C) | Print Time (hrs) |

|---|---|---|---|---|

| Prusa i3 MK3S+ | 250 x 210 x 210 | 100 | 180-280 | 8 |

| Ender 3 Pro | 220 x 220 x 250 | 60 | 180-260 | 12 |

| Creality CR-10 | 300 x 300 x 400 | 100 | 180-280 | 16 |

| Ultimaker S5 | 330 x 240 x 300 | 120 | 180-280 | 10 |

As you can see, the print time for the same object can vary significantly depending on the printer model.

Advantages and Disadvantages of Different Printer Types for Fast Printing

Different printer types have advantages and disadvantages for fast printing.

- FDM printersare the most common type of 3D printer. They are relatively inexpensive and easy to use. However, they are also relatively slow compared to other printer types.

- SLA printersuse a laser to cure liquid resin, which produces high-quality prints with smooth surfaces. However, SLA printers are more expensive than FDM printers and require more specialized materials.

- SLS printersuse a laser to fuse powdered material, which produces strong and durable prints. However, SLS printers are even more expensive than SLA printers and require specialized materials.

Ultimately, the best printer type for fast printing depends on your specific needs and budget.

Filament Type

The type of filament used in 3D printing can significantly impact the print time. Different filament types have varying properties, such as diameter, melting point, and flowability, which affect the printing process and the time it takes to complete a print.

Filament diameter is a crucial factor that influences print time. Thinner filaments (e.g., 1.75 mm) require less material to be extruded per layer, resulting in faster printing speeds compared to thicker filaments (e.g., 3 mm). Thinner filaments also allow for finer details and smoother surfaces.

The melting point of the filament determines the temperature at which it transitions from a solid to a molten state. Filaments with lower melting points (e.g., PLA) can be printed at lower temperatures, reducing the time required for the material to melt and flow through the nozzle.

The flowability of the filament refers to its ability to move smoothly through the nozzle. Filaments with better flowability (e.g., ABS) can be extruded more quickly, leading to faster printing speeds.

Print Time Comparison of Different Filament Types

| Filament Type | Diameter (mm) | Melting Point (°C) | Flowability | Estimated Print Time |

|---|---|---|---|---|

| PLA | 1.75 | 175-190 | Good | Fastest |

| ABS | 1.75 | 230-250 | Excellent | Faster |

| PETG | 1.75 | 250-270 | Moderate | Average |

| Nylon | 1.75 | 260-280 | Poor | Slowest |

Environmental Factors

Environmental factors such as temperature and humidity can significantly impact 3D printing time. Maintaining a controlled printing environment is crucial to ensure optimal print quality and minimize the risk of print failures.

Temperature

The temperature of the printing environment affects the material’s flow and adhesion properties. Ideal printing temperatures vary depending on the filament type. For instance, PLA filaments perform best at temperatures between 190-220°C, while ABS filaments require higher temperatures of 230-250°C.

When the printing environment is too cold, the material may not flow properly, leading to under-extrusion and weak layer bonding. Conversely, if the environment is too hot, the material may become too fluid, resulting in oozing, warping, and dimensional inaccuracies.

Humidity

Humidity can also affect 3D printing. High humidity levels can cause the filament to absorb moisture, which can lead to bubbles and voids in the printed object. This can weaken the print’s structure and increase the risk of print failures.

Maintaining a controlled printing environment with optimal temperature and humidity ranges is essential for successful 3D printing. Here are some tips for optimizing the printing environment:

- Use a dedicated printing enclosure to control temperature and humidity.

- Install a dehumidifier to reduce humidity levels in the printing area.

- Monitor the temperature and humidity using a hygrometer or a dedicated monitoring system.

- Adjust the printing parameters (temperature, speed, etc.) based on the environmental conditions.

| Filament Type | Optimal Temperature (°C) | Optimal Humidity (%) |

|---|---|---|

| PLA | 190-220 | 30-50 |

| ABS | 230-250 | 15-30 |

| PETG | 220-250 | 20-40 |

| TPU | 200-230 | 20-40 |

| Nylon | 240-260 | 15-30 |

Additionally, a code snippet can be used to monitor the temperature and humidity of the printing environment and alert the user if the conditions are outside the optimal range:

import RPi.GPIO as GPIOimport time# Set up GPIO pinstemperature_sensor_pin = 4humidity_sensor_pin = 17# Set up GPIO inputsGPIO.setmode(GPIO.BCM)GPIO.setup(temperature_sensor_pin, GPIO.IN)GPIO.setup(humidity_sensor_pin, GPIO.IN)# Set up threshold valuesoptimal_temperature_range = (20, 25)optimal_humidity_range = (30, 50)# Monitor temperature and humiditywhile True: temperature = GPIO.input(temperature_sensor_pin) humidity = GPIO.input(humidity_sensor_pin) # Check if temperature or humidity is outside optimal range if temperature < optimal_temperature_range[0] or temperature > optimal_temperature_range[1]: print("Temperature is outside optimal range:", temperature) if humidity < optimal_humidity_range[0] or humidity > optimal_humidity_range[1]: print("Humidity is outside optimal range:", humidity) # Sleep for 1 second time.sleep(1)

Advanced Techniques: How Long Does It Take To 3d Print

Advanced techniques for reducing print time include using multiple nozzles, optimizing travel paths, and utilizing dissolvable supports. Each technique offers unique advantages and disadvantages, making them suitable for different applications.

Using Multiple Nozzles

Using multiple nozzles can significantly reduce print time by allowing multiple parts of a model to be printed simultaneously. This technique is particularly beneficial for models with complex geometries or those that require multiple colors or materials. However, it requires specialized printers and can be more complex to set up and calibrate.

Optimizing Travel Paths

Optimizing travel paths involves minimizing the distance the print head travels between different parts of the model. This can be achieved through software algorithms that calculate the most efficient path for the print head to follow. By reducing travel time, overall print time can be reduced.

Using Dissolvable Supports, How long does it take to 3d print

Dissolvable supports are temporary structures printed alongside the model to provide support for overhanging or complex features. After printing, the supports can be dissolved in a solvent, leaving behind the finished model. This technique eliminates the need for manual support removal, saving time and improving print quality.

Case Studies

Case studies provide valuable insights into the practical application of print time reduction techniques. By examining real-world examples, we can learn from the successes and challenges encountered, gaining a deeper understanding of the factors that influence print time and the strategies that can be employed to minimize it.

One notable case study involved a large-scale 3D printing project for a construction application. The initial print time estimates were excessive, posing a significant challenge to the project’s timeline. To address this, the team implemented a combination of print time optimization techniques, including:

Layer Height Optimization

By reducing the layer height, the team was able to achieve smoother surface finishes and reduce the overall print time. This was particularly effective for complex models with intricate details.

Infill Density Considerations

The team carefully optimized the infill density of the printed parts. By reducing the infill density in areas where structural integrity was not critical, they were able to significantly reduce print time without compromising the strength of the parts.

Print Speed Optimization

The team experimented with different print speeds to find the optimal balance between print quality and print time. They identified the maximum print speed at which the desired quality could be maintained, reducing print time without sacrificing accuracy.

Metrics and Data

The team meticulously tracked print times and analyzed the impact of each optimization technique. By quantifying the improvements, they were able to demonstrate the effectiveness of their approach. In the end, they successfully reduced the overall print time by 25%, enabling the project to be completed on schedule.

Innovative Approaches

In addition to the standard optimization techniques, the team also explored innovative approaches to reduce print time. They developed custom slicing profiles that optimized the toolpath and minimized travel time. They also experimented with adaptive layer height, where the layer height was varied throughout the print to improve surface quality in critical areas while reducing print time in less critical areas.

This case study highlights the importance of a comprehensive approach to print time reduction. By combining multiple optimization techniques and exploring innovative solutions, the team was able to achieve significant improvements in print time without compromising the quality of the printed parts.

Time-Saving Tips

Optimizing the print time of 3D prints involves a combination of smart design, efficient slicing, and well-maintained printing hardware. Here are some practical tips and tricks to help you reduce print time and improve your 3D printing experience.

The key to faster printing lies in optimizing the print process at every stage, from model design to printer maintenance. By implementing these time-saving techniques, you can significantly reduce print times without compromising the quality of your prints.

Model Design Optimization

- Design hollow models with internal cavities to reduce material usage and print time.

- Simplify complex geometries and remove unnecessary details to minimize print time.

- Orient models strategically on the print bed to reduce support structures and print time.

Slicing Settings Optimization

- Use adaptive layer heights to reduce print time in areas with less detail.

- Adjust infill density and pattern to optimize strength while minimizing print time.

- Enable “print acceleration” settings to reduce travel time between print lines.

Printer Maintenance and Calibration

- Regularly clean and maintain the printer to prevent clogs and ensure smooth operation.

- Calibrate the printer regularly to ensure accurate movements and prevent print errors.

- Use high-quality filaments and adjust extrusion temperatures to optimize flow and reduce print time.

Slicing Software Comparison

| Slicing Software | Features | Impact on Print Time |

|---|---|---|

| Cura | Easy-to-use interface, extensive customization options | Faster slicing times, optimized print settings |

| Simplify3D | Advanced slicing algorithms, detailed print control | Slower slicing times, but potential for faster printing |

| PrusaSlicer | Open-source, community-driven development | Moderate slicing times, customizable profiles |

Print Time Bottleneck Checklist

- Slow slicing times: Upgrade slicing software or simplify model geometry.

- Excessive support structures: Optimize model orientation or reduce support density.

- Printer hardware issues: Check for clogs, misalignment, or mechanical problems.

- Inadequate cooling: Increase fan speed or optimize print settings to reduce warping.

- Inconsistent extrusion: Calibrate printer and adjust extrusion temperature.

Benchmarking

Benchmarking print times against industry standards is crucial for optimizing print efficiency and identifying areas for improvement. By comparing print times across different printers and materials, manufacturers and users can gain insights into the performance of their equipment and identify potential bottlenecks.

To measure and compare print times, several factors need to be considered, including the printer model, nozzle size, layer height, infill density, print speed, and filament type. By standardizing these parameters, it becomes possible to obtain accurate and meaningful comparisons.

Industry Standards

Industry standards for print times vary depending on the specific application and materials used. However, certain benchmarks can provide a general reference point. For example, a typical FDM printer with a 0.4mm nozzle and a layer height of 0.2mm can print a 100mm cube in approximately 4-6 hours.

This time may vary depending on the infill density and print speed settings.

Comparison Table

The following table provides a comparison of print times for different printers and models:

| Printer Model | Nozzle Size (mm) | Layer Height (mm) | Infill Density (%) | Print Speed (mm/s) | Print Time (hours) |

|---|---|---|---|---|---|

| XYZ da Vinci Pro | 0.4 | 0.2 | 20 | 50 | 4.5 |

| Ultimaker 3 | 0.4 | 0.1 | 20 | 60 | 6.0 |

| Prusa i3 MK3S+ | 0.4 | 0.15 | 25 | 55 | 5.5 |

| Creality Ender 3 V2 | 0.4 | 0.2 | 15 | 60 | 4.0 |

Future Trends

The future of 3D printing holds exciting prospects for reducing print times. Advancements in materials, hardware, and software are converging to enable faster and more efficient printing processes.

Innovative Techniques and Approaches

* Multi-material printing:Using multiple materials simultaneously can reduce the need for post-processing and assembly, saving time.

High-speed printing

Advanced printers with optimized hardware and slicing algorithms can achieve significantly faster print speeds.

Adaptive slicing

Software that automatically adjusts slicing parameters based on model geometry can optimize print time without compromising quality.

AI-assisted printing

Machine learning algorithms can analyze print data and predict optimal settings, reducing trial-and-error time.

Materials Advancements

* High-temperature filaments:Materials that can withstand higher temperatures allow for faster printing by enabling thicker layers and higher extrusion rates.

Low-friction filaments

Filaments with reduced friction reduce resistance during printing, resulting in faster extrusion and shorter print times.

Nanocomposite filaments

Filaments reinforced with nanoparticles improve mechanical properties, allowing for thinner layers and faster printing speeds.

Hardware Innovations

* Multi-nozzle printers:Printers with multiple nozzles can print multiple parts or colors simultaneously, reducing overall print time.

Large-volume printers

Printers with larger build volumes allow for the production of larger parts in a single print, eliminating the need for assembly.

High-precision printers

Printers with improved precision can print with finer details and tighter tolerances, reducing the need for post-processing and saving time.

FAQs

What are the primary factors that affect 3D print time?

Model size, layer height, infill density, print speed, nozzle size, and extrusion width are the key factors influencing print time.

How does layer height impact print time?

Decreasing layer height generally increases print time, as it requires more layers to build the model.

What is the relationship between infill density and print time?

Higher infill density leads to longer print times, as it requires more material to fill the interior of the model.

Can increasing print speed always reduce print time?

While increasing print speed can reduce print time, it may compromise print quality and increase the risk of printing errors.