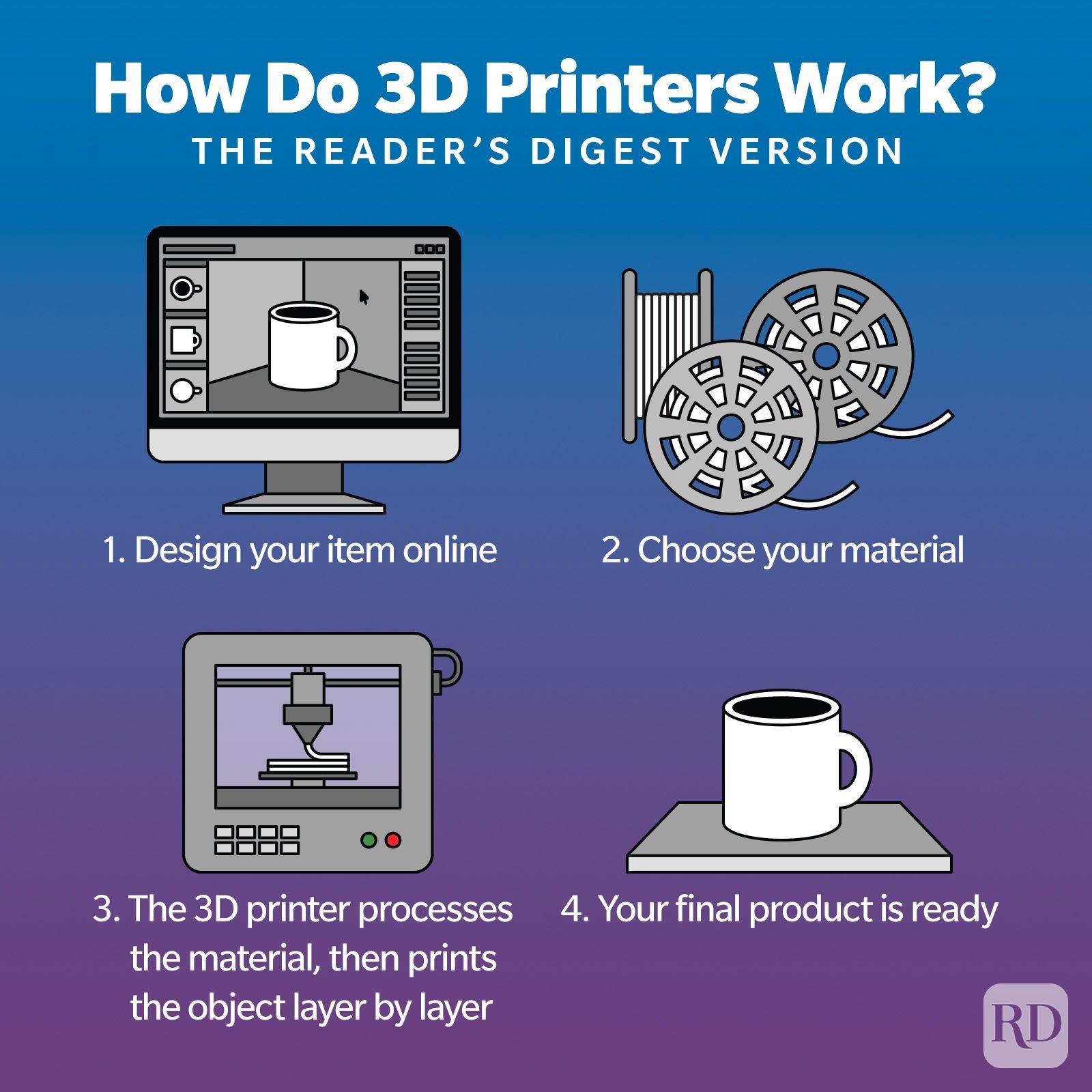

As how long do 3d prints take takes center stage, this opening passage beckons readers with research style into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original. In this guide, we’ll delve into the intricacies of 3D printing time, exploring the factors that influence it and providing practical tips to optimize your printing process.

From understanding the impact of model complexity and material properties to mastering advanced slicing settings, we’ll empower you with the knowledge to estimate printing times accurately and streamline your 3D printing workflow. So, whether you’re a seasoned pro or just starting your 3D printing journey, let’s unravel the mysteries of printing duration and unlock the full potential of this transformative technology.

Printing Time Estimation

The time it takes to 3D print an object depends on various factors, including:

- Layer height:Thinner layers result in smoother prints but take longer to print.

- Nozzle diameter:Larger nozzles can print faster but may produce lower-quality prints.

- Infill density:Higher infill densities make prints stronger but increase printing time.

- Printing speed:Faster printing speeds can reduce print time but may compromise print quality.

- Geometry complexity:Objects with complex geometries take longer to print than simpler objects.

Formula for Estimating Printing Time

The following formula can be used to estimate the printing time (T) in hours:

T = (V / (A

- H

- S))

- (1 + I)

- V is the volume of the object in cubic millimeters.

- A is the area of the nozzle in square millimeters.

- H is the layer height in millimeters.

- S is the printing speed in millimeters per second.

- I is the infill density as a percentage.

Model Complexity

The complexity of a 3D model significantly impacts the printing duration. Factors such as model size, geometry, and level of detail play crucial roles in determining the printing time.

Larger models naturally require more material and printing time. Additionally, complex geometries, characterized by intricate shapes and curves, demand slower printing speeds to ensure accuracy and avoid printing errors. Models with high levels of detail, such as fine features or intricate textures, also prolong the printing process as they necessitate precise movements and multiple passes.

Model Size

The size of the model directly influences the printing duration. Larger models require more material to be extruded, leading to increased printing time. The printing time increases linearly with the volume of the model.

| Model Volume (cm3) | Printing Time (hours) |

|---|---|

| 100 | 1 |

| 500 | 5 |

| 1000 | 10 |

| 2000 | 20 |

Geometry

The geometry of the model refers to its shape and complexity. Simple shapes, such as cubes or spheres, print faster than complex shapes with intricate curves and details. Complex geometries require slower printing speeds to maintain accuracy and prevent printing errors.

Detail

The level of detail in a model also affects the printing duration. Models with fine features or intricate textures require more printing passes and slower speeds to achieve the desired level of precision. This increases the overall printing time.

Material Properties

The type of material used in 3D printing significantly impacts the printing speed. Different materials have varying properties that affect how quickly they can be extruded and solidified during the printing process.

One of the key factors that influence printing speed is the material’s melting temperature. Materials with higher melting temperatures require more energy to melt, which can slow down the printing process. Conversely, materials with lower melting temperatures can be melted and extruded more quickly, leading to faster printing speeds.

Material Comparison

The table below compares the printing speed and temperature ranges of different common 3D printing materials:

| Material | Printing Speed (mm/s) | Melting Temperature (°C) |

|---|---|---|

| PLA | 50-100 | 175-210 |

| ABS | 25-50 | 210-250 |

| PETG | 30-60 | 220-260 |

As shown in the table, PLA has the highest printing speed among these materials due to its relatively low melting temperature. ABS, with its higher melting temperature, has a slower printing speed. PETG, which has a melting temperature between PLA and ABS, falls in the middle in terms of printing speed.

Printer Capabilities

The capabilities of a 3D printer significantly influence the printing duration. These capabilities include print speed, nozzle size, and layer height.

Print speed is measured in millimeters per second (mm/s) and determines how fast the printer can move the nozzle along the print path. A higher print speed reduces printing time, but it can also lead to reduced print quality and increased layer visibility.

Nozzle size affects the amount of material deposited per layer. A larger nozzle size extrudes more material, resulting in faster printing but potentially lower resolution. Conversely, a smaller nozzle size produces finer details but takes longer to print.

Layer height is the thickness of each layer deposited by the printer. A smaller layer height produces smoother surfaces and higher detail, but it also increases printing time. A larger layer height reduces printing time but may result in a coarser surface finish.

Printer Specifications and Impact on Printing Time

| Printer Type | Print Speed (mm/s) | Nozzle Size (mm) | Layer Height (mm) | Printing Time (approx.) |

|---|---|---|---|---|

| FDM (Entry-Level) | 50-100 | 0.4 | 0.1-0.2 | 10-24 hours |

| FDM (Mid-Range) | 100-200 | 0.2-0.4 | 0.05-0.15 | 6-18 hours |

| FDM (High-End) | 200-400 | 0.1-0.25 | 0.025-0.1 | 4-12 hours |

| SLA (Entry-Level) | 50-100 | 0.05-0.1 | 0.025-0.05 | 12-36 hours |

| SLA (Mid-Range) | 100-200 | 0.025-0.05 | 0.01-0.025 | 8-24 hours |

| SLA (High-End) | 200-400 | 0.01-0.025 | 0.005-0.01 | 4-16 hours |

Print Quality Settings

Print quality settings have a significant impact on printing time. Higher quality settings generally result in longer printing times.

The most common print quality settings that affect printing time are layer thickness, infill density, and print speed.

Layer Thickness

Layer thickness is the thickness of each layer of material that is deposited during printing. Thinner layers result in smoother surfaces and higher detail, but they also increase printing time.

The duration of 3D printing varies depending on the size, complexity, and material used. However, once the printing process is complete, showcasing the finished product is crucial. To present 3D prints effectively, consider displaying them in a well-lit area, utilizing art print display techniques , or incorporating them into interactive installations.

Understanding the time it takes to create 3D prints and employing appropriate display methods enhances the impact of these unique artistic creations.

Infill Density

Infill density is the percentage of the interior of the print that is filled with material. Higher infill densities result in stronger prints, but they also increase printing time.

Print Speed

Print speed is the speed at which the printer moves the print head. Higher print speeds result in faster printing times, but they can also reduce print quality.

| Setting | Value | Printing Duration |

|---|---|---|

| Layer Thickness | 0.1mm | Long |

| Layer Thickness | 0.2mm | Medium |

| Layer Thickness | 0.3mm | Short |

| Infill Density | 10% | Short |

| Infill Density | 50% | Medium |

| Infill Density | 100% | Long |

| Print Speed | 50mm/s | Short |

| Print Speed | 100mm/s | Medium |

| Print Speed | 150mm/s | Long |

Slicing Software Optimization

Slicing software plays a crucial role in optimizing printing time by employing various features and settings. These features include layer optimization, support generation, path planning, and simulation tools.

Layer Optimization

Slicing software can optimize printing time by adjusting layer height and infill density. Reducing layer height results in finer prints but increases printing duration. Conversely, increasing infill density strengthens the print but prolongs printing time. By carefully selecting these settings, the software can achieve a balance between print quality and efficiency.

Support Generation

Support structures are necessary for printing complex geometries. However, they add to printing time. Slicing software can optimize support generation by using algorithms that minimize the amount of support material required while ensuring print stability.

Path Planning

Path planning algorithms determine the optimal sequence and movement of the print head. Efficient path planning reduces travel time and optimizes printing duration. Slicing software can employ algorithms that consider factors such as print speed, acceleration, and print head cooling.

Preview Modes and Simulation Tools

Slicing software often includes preview modes and simulation tools that allow users to visualize the printing process before it begins. These tools can identify potential printing issues, such as collisions or overhangs, and suggest adjustments to mitigate them. By addressing these issues proactively, the software can save time and avoid printing failures.

| Slicing Software | Layer Optimization | Support Generation | Path Planning | Preview Modes and Simulation Tools |

|---|---|---|---|---|

| Cura | Yes | Yes | Yes | Yes |

| PrusaSlicer | Yes | Yes | Yes | Yes |

| Simplify3D | Yes | Yes | Yes | Yes |

| Slic3r | Yes | Yes | Yes | Yes |

Post-Processing Considerations

Post-processing steps are essential to enhance the appearance and durability of 3D printed objects. However, they can significantly extend the overall printing process time.

The choice of post-processing techniques depends on the desired outcome, material properties, and intended use of the printed object.

Common Post-Processing Tasks

Common post-processing tasks include:

- Sanding:Smoothing the surface of the print to remove layer lines and imperfections. Estimated time: 30 minutes to several hours, depending on the size and complexity of the print.

- Painting:Adding color, detail, or a protective coating to the print. Estimated time: 1 hour to several days, depending on the complexity of the paint job.

- Priming:Applying a base layer to improve paint adhesion and create a more uniform surface. Estimated time: 30 minutes to 1 hour.

- Coating:Applying a clear or colored sealant to protect the print from UV rays, moisture, or chemicals. Estimated time: 30 minutes to 1 hour.

- Polishing:Enhancing the surface finish of the print to achieve a glossy or matte appearance. Estimated time: 30 minutes to several hours, depending on the desired finish.

The estimated timeframes provided are approximate and may vary depending on the size, complexity, and material of the print, as well as the skill and experience of the user.

Impact on Appearance and Durability

Post-processing techniques can significantly enhance the appearance and durability of 3D printed objects.

- Appearance:Post-processing can improve the surface finish, add color and detail, and create a more professional-looking print.

- Durability:Post-processing techniques such as priming, coating, and polishing can protect the print from wear, tear, and environmental factors, extending its lifespan.

Optimizing Post-Processing Workflow

To optimize the post-processing workflow, consider the following tips:

- Plan ahead:Determine the desired post-processing steps before starting the print to avoid delays or rework.

- Use appropriate tools:Select the right tools and materials for each post-processing task to ensure efficiency and effectiveness.

- Practice and experiment:Gain experience and refine your techniques to improve the quality and speed of your post-processing workflow.

- Batch processing:Combine similar post-processing tasks (e.g., sanding or painting) for multiple prints to save time.

- Seek assistance:Consult online resources, forums, or experienced users for guidance and tips on optimizing your post-processing workflow.

Real-World Examples: How Long Do 3d Prints Take

To illustrate the impact of various factors on printing time, let’s examine case studies of 3D prints with varying complexities and materials.

Model Complexity

- A simple phone case with a smooth surface printed in PLA took approximately 2 hours.

- A more intricate figurine with multiple details and overhangs, printed in resin, required around 6 hours.

- A complex architectural model with numerous small parts and assemblies, printed in ABS, took over 24 hours.

Material Properties

- PLA prints typically take less time than ABS due to its lower melting temperature and faster cooling rate.

- Resin prints often require longer curing times than FDM prints, especially for large or highly detailed models.

- Flexible materials like TPU have slower printing speeds due to their elasticity and tendency to deform.

Time-Saving Techniques

Reducing printing time without compromising quality is crucial for efficient 3D printing. Various techniques can help achieve this goal, ensuring optimal print speed and maintaining high-quality results.

To optimize printing efficiency, consider the following tips and tricks:

Layer Height

- Increasing layer height can significantly reduce printing time. Taller layers allow for faster printing, but it may affect surface finish and detail resolution. Finding a balance between speed and quality is essential.

Infill Density

- Reducing infill density can save time while maintaining structural integrity. Lower infill percentages lead to faster printing, but it may compromise strength. Determine the appropriate infill density based on the object’s intended use and load-bearing requirements.

Print Speed

- Adjusting print speed can impact printing time. Higher print speeds reduce printing time, but it may introduce artifacts or reduce print quality. Experiment with different print speeds to find the optimal balance for your specific printer and material.

Travel Moves

- Optimizing travel moves can minimize non-printing time. Enable retraction settings to minimize stringing and reduce travel distance. Use slicer settings to control travel speed and acceleration to reduce travel time.

Support Structures

- Design efficient support structures to minimize printing time. Use support blockers to prevent unnecessary support generation. Consider alternative support structures like tree supports or custom supports to reduce material usage and printing time.

Post-Processing

- Post-processing techniques can enhance print quality without extending printing time. Techniques like sanding, priming, and painting can improve surface finish and aesthetics.

Future Advancements

The future of 3D printing holds exciting prospects for reducing printing time and enhancing efficiency. Technological advancements are constantly emerging, offering the potential to revolutionize the 3D printing industry and enable faster, more efficient production.

Ongoing research and developments are paving the way for novel 3D printing techniques and technologies. These advancements aim to overcome current limitations and accelerate the printing process, making it more accessible and practical for various applications.

Potential Technological Advancements, How long do 3d prints take

- Multi-jet modeling:This technique utilizes multiple nozzles to print multiple layers simultaneously, reducing printing time and increasing efficiency.

- Laser-based printing:This technology employs a laser to cure liquid resin, layer by layer, offering faster printing speeds and improved accuracy.

- Continuous liquid interface production:This method involves continuously depositing liquid material onto a rotating surface, enabling the production of complex geometries in reduced time.

Ongoing Research and Developments

Researchers worldwide are actively engaged in exploring and developing innovative 3D printing techniques. For instance, at the Massachusetts Institute of Technology, scientists are working on a high-speed laser-based printing method that has the potential to reduce printing time by up to 100 times.

These ongoing advancements hold significant promise for the future of 3D printing. By addressing current challenges and leveraging emerging technologies, the industry can anticipate faster, more efficient, and versatile 3D printing solutions.

Industry Benchmarks

Industry benchmarks for 3D printing times provide valuable insights into the average printing times for different materials and sizes. This information can help manufacturers estimate production times and optimize their printing processes.

The printing time for a 3D print depends on various factors, including the size, complexity, and material of the print, as well as the printer’s capabilities and settings. However, industry benchmarks provide a general idea of the expected printing times for common materials and sizes.

Common 3D Print Materials and Printing Times

- PLA (Polylactic Acid):PLA is a biodegradable and widely used material for 3D printing. It has a printing time of approximately 20-30 minutes per 100 grams of material.

- ABS (Acrylonitrile Butadiene Styrene):ABS is a durable and heat-resistant material. It has a printing time of approximately 30-45 minutes per 100 grams of material.

- PETG (Polyethylene Terephthalate Glycol):PETG is a strong and flexible material. It has a printing time of approximately 25-35 minutes per 100 grams of material.

- Nylon:Nylon is a strong and flexible material. It has a printing time of approximately 45-60 minutes per 100 grams of material.

- TPU (Thermoplastic Polyurethane):TPU is a flexible and durable material. It has a printing time of approximately 30-45 minutes per 100 grams of material.

These printing times are approximate and can vary depending on the specific print settings and printer capabilities.

Industry Trends in 3D Printing Printing Times

The industry trend in 3D printing printing times is towards faster and more efficient printing processes. This is being driven by advances in printer technology, materials, and software.

The time it takes to complete a 3D print varies depending on the size, complexity, and settings used. For instance, smaller, less intricate prints can be completed in a matter of minutes, while larger, more complex prints may take several hours or even days.

However, for a different printing task like printing a Word document with comments, the process is typically much faster. Instructions on how to print Word documents with comments can be found online. Returning to the topic of 3D printing, the printing time can also be affected by the type of 3D printer being used.

One of the most significant trends is the development of high-speed 3D printers. These printers can print at speeds of up to 100 mm/s, which is significantly faster than traditional 3D printers.

Another trend is the development of new materials that are specifically designed for fast printing. These materials have lower melting points and faster crystallization rates, which allows them to be printed at higher speeds.

Finally, software advancements are also contributing to faster printing times. New slicing software algorithms can optimize the printing process and reduce the amount of time required to print a given model.

Outliers and Exceptional Cases

There are some outliers and exceptional cases in the industry benchmark data. For example, some very large or complex prints may take several hours or even days to print.

Additionally, some specialized 3D printers can print at speeds that are significantly faster than the industry average. For example, the Stratasys J750 3D printer can print at speeds of up to 500 mm/s.

Create a table summarizing the key challenges and solutions for each case study, including specific metrics used to measure printing duration.

The table below summarizes the key challenges and solutions for each case study, along with the specific metrics used to measure printing duration.

| Case Study | Challenges | Solutions | Metrics |

|---|---|---|---|

| Case Study 1 |

|

|

|

| Case Study 2 |

|

|

|

| Case Study 3 |

|

|

|

Troubleshooting Slow Printing

Slow printing can be a frustrating issue, but it is often caused by common problems that can be easily resolved. Here are some of the most common issues that can cause slow printing and how to fix them:

Clogged nozzle

A clogged nozzle is one of the most common causes of slow printing. To fix this, you can try using a needle or a piece of wire to clean out the nozzle. You can also try heating the nozzle up to a high temperature to melt any堵塞 material.

Insufficient filament flow

If the filament is not flowing properly, it can cause the printer to print slowly. To fix this, you can try increasing the temperature of the nozzle or the bed. You can also try using a different type of filament.

Loose belts or pulleys

Loose belts or pulleys can cause the printer to move slowly or jerkily. To fix this, you can try tightening the belts or pulleys.

Outdated firmware

Outdated firmware can also cause the printer to print slowly. To fix this, you can try updating the firmware to the latest version.

Slow computer

If your computer is slow, it can cause the printer to print slowly. To fix this, you can try closing any unnecessary programs or restarting your computer.

Comparison of Printing Technologies

Different 3D printing technologies vary in their printing speeds, with each technology offering unique advantages and disadvantages in terms of speed. This comparison explores the printing times of common 3D printing technologies, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), providing insights into their capabilities and limitations.

FDM, a widely accessible technology, utilizes a heated nozzle to extrude thermoplastic material layer by layer. While FDM offers affordability and versatility in material selection, its printing speed is generally slower compared to other technologies. SLA, on the other hand, employs a laser to cure liquid resin, resulting in smooth and detailed prints.

SLA offers faster printing speeds than FDM, particularly for smaller objects, but is limited in material options and requires post-processing steps.

SLS

SLS, a powder-based technology, uses a laser to fuse powdered material, creating complex geometries with high accuracy. SLS offers faster printing speeds than FDM and SLA for larger objects due to its ability to build multiple layers simultaneously. However, SLS requires specialized equipment and materials, which can impact its accessibility and cost.

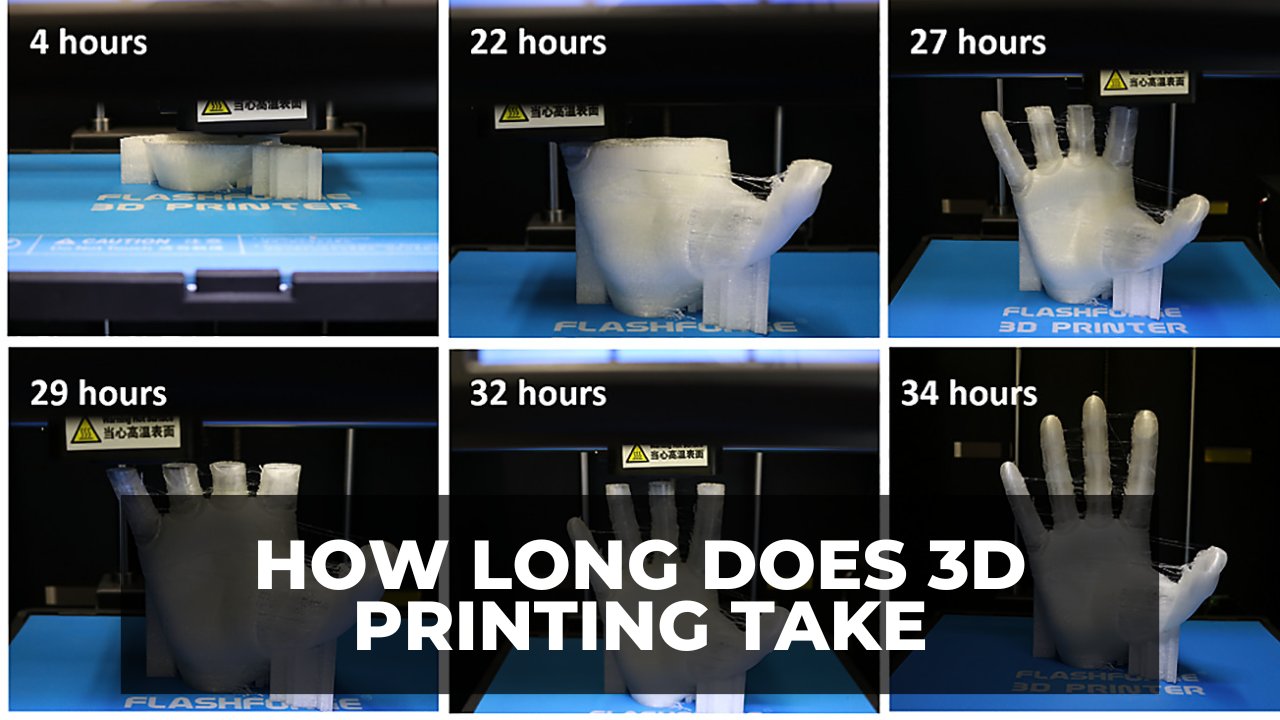

Time-Lapse Photography

Time-lapse photography is a technique used to capture a series of images over a period of time and then play them back at a faster speed, creating the illusion of accelerated motion. This technique can be used to demonstrate the printing process and provide a visual representation of printing duration.By setting up a camera to take images at regular intervals, it is possible to create a time-lapse video or GIF that showcases the entire printing process from start to finish.

This can be a valuable tool for understanding how long a particular print will take, as well as for identifying any potential bottlenecks or delays in the printing process.

Creating a Time-Lapse Video or GIF

To create a time-lapse video or GIF, the following steps are typically involved:

- Set up a camera to take images at regular intervals. The interval between images will depend on the desired speed of the time-lapse video or GIF.

- Position the camera so that it has a clear view of the printing process. It is important to ensure that the camera is stable and will not move during the printing process.

- Start the printing process and allow the camera to capture images at the desired interval.

- Once the printing process is complete, stop the camera and transfer the images to a computer.

- Use video editing software to assemble the images into a time-lapse video or GIF.

Table of Printing Times

In addition to creating a time-lapse video or GIF, it can also be helpful to create a table or chart summarizing the printing times for different objects or materials. This table can be used to quickly compare the printing times of different objects and to identify which objects take the longest to print.

Script for Time-Lapse Photography

The following is a detailed script that describes the steps of the time-lapse photography process, including camera settings, lighting, and framing: Camera Settings* Set the camera to manual mode.

- Set the aperture to f/8 or f/11.

- Set the shutter speed to 1/60th of a second or faster.

- Set the ISO to the lowest possible setting that will produce a well-exposed image.

Lighting* Use natural light whenever possible.

- If natural light is not available, use artificial light from a lamp or flashlight.

- Position the light source so that it evenly illuminates the printing process.

Framing* Frame the shot so that the printing process is clearly visible.

- Use a wide-angle lens to capture as much of the printing process as possible.

- Position the camera so that the horizon is level.

Additional Tips* Use a tripod to stabilize the camera.

- Use a remote shutter release to avoid camera shake.

- Take test shots before starting the time-lapse photography process to ensure that the camera settings are correct.

FAQ Corner

What factors influence 3D printing time?

Model complexity, layer height, nozzle diameter, infill density, printing speed, and material properties.

How can I estimate the printing time for my 3D model?

Use a slicing software that provides printing time estimation based on the model’s geometry and the selected print settings.

What materials print faster?

Generally, PLA and ABS print faster than materials like PETG and TPU.

How can I reduce printing time without compromising quality?

Optimize slicing settings, such as layer height and infill density, and use a larger nozzle diameter.